Spindle Cutters

Headed into Carbatec today to have a quick play with a spindle moulder they have on the shop floor. Wasn’t in a position to fire it up, but still it was very interesting to explore the machine a bit closer.

The spindle chosen was 30mm diameter, to match the cutters I have from Toolstoday.com

Just taking the spacers off the spindle, and I quickly became aware that the tolerances on a spindle moulder are quite precise. The two nuts on the top of the spindle have opposite threads, decreasing the possibility that they can work loose. The moulder is reversible, so this also explains why the nuts have opposing threads. The reversibility of the spindle moulder is one of the distinct advantages it has over a router table. (Of course you also have to turn the cutter upside down if you are going to run it backwards, so it is an obvious advantage the cutters do not have an attached shaft like a router bit!)

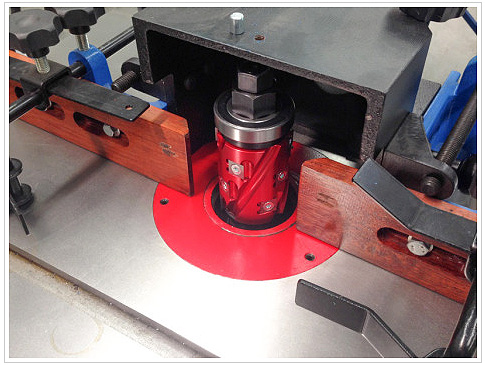

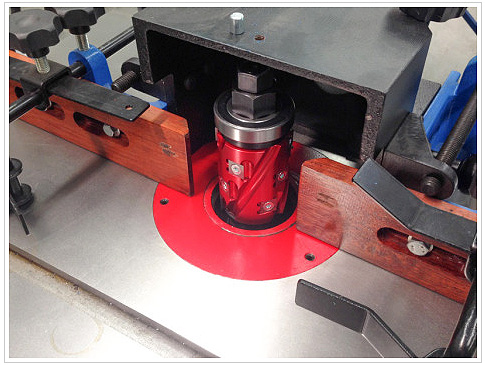

The first cutter I set up was the Insert Spiral Jointing Cutter.

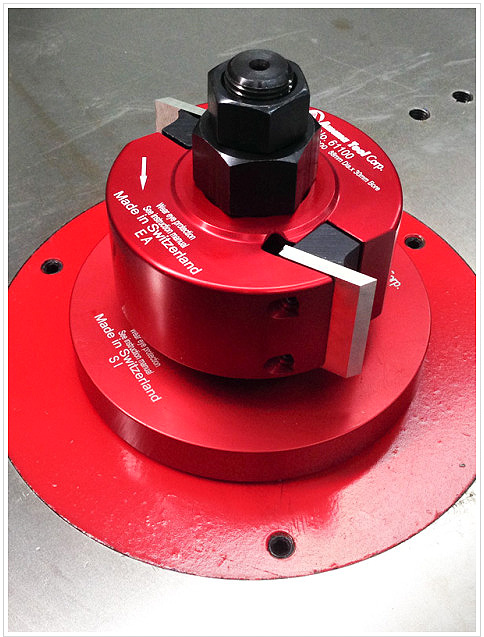

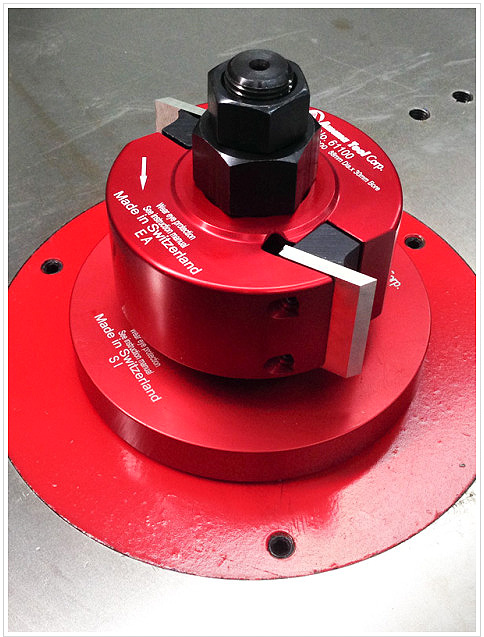

It has 12 cutters set in a staggered pattern around a spiral – although not a slicing action, this still has the advantage of easy chip clearance, and a much lower power requirement than if it was full width straight blades. Chippers are reportedly a lot quieter than straight cutters as well.

Each tooth has 4 sides, so keeping blades sharp is a simple matter of rotating the cutter to have a new edge doing the work. An engraved dot on each blade helps you keep track of which edges are still fresh.

Replacing carbide cutters are also quite cheap if one is used up, or breaks. I haven’t seen one break myself, on this or on other cutters (I have some router bits that use them), but it is potential if you hit something hard, carbide being brittle, as well as exceptionally hard itself.

They are a great looking cutter, and I can assure you the carbides are sharp (from a bit too personal experience while handling the cutter – just a slight scratch, but a reminder just how sharp the blades are).

The cutter in this case has a wider diameter hole than needed for a 30mm shaft, but reducers adapt the cutter to fit your particular machine. The tolerances are surprisingly close – not too tight that it jambs on, but you can feel it slip on the shaft without any play whatsoever.

I have set this cutter up with a bearing guide above, but you could also choose to have it below as well if preferred for the particular application. The fence is somewhat optional because of the bearing, but I would suggest it is a safety feature, preventing work making an undue degree of contact with the cutter (particularly at the wrong angle). The fence on this particular spindle moulder is very agricultural, and would quickly frustrate me with the various holddowns (sounds like a perfect situation for the MagFence, and/or power feed!)

One of the advantages of this setup over a traditional jointer, is that bearing (called a rub collar in this application) being ‘the fence’ means you are not limited to planing straight surfaces only. Even if doing straight surfaces, after flattening one face of a board, it can then rest fully on the table when you machine the edge, rather than trying to hold it against the vertical fence of the jointer.

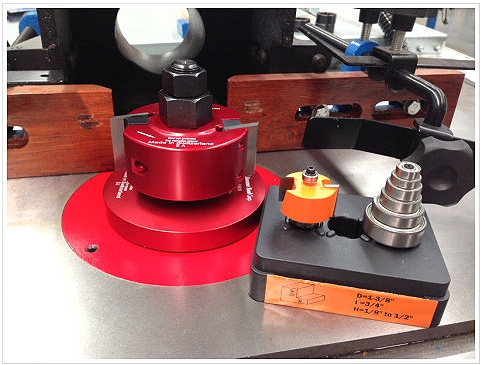

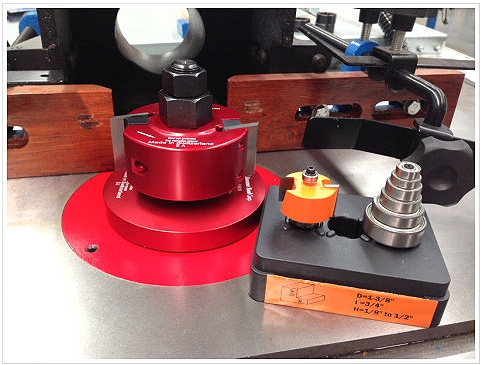

The other moulder cutter I set up was the Profile Pro Multi-Shaper starter set, along with a massive rub collar! They say it is for arched or cathedral doors, but I reckon it is for cathedral arches!

In this case I chose to mount the rub collar below the cutter head. It spins freely (and is proud of the table), and allows you control over what you are cutting by following an attached template. Again, using the fence is mandatory, if only for safety’s sake.

Although I am only showing the straight cutters here, there are 7 different profiles in the set, and a whole heap more you can buy (relatively cheaply). There is also a blank blade set if you want to have a workshop machine a specific profile you require.

To give you an idea of the scale we are talking about here, if you were using a router for this job, this is the equivalent router bit.

That certainly says something doesn’t it!

I am hoping at the show this weekend to be able to fire up one (or both) these cutters, to see the things in action not sure which stand will have a working moulder as yet – Gabbett Machinery will certainly have their combo machine there – hope they are provided sufficient power!

Originally posted on October 15th, 2013 by Stuart

Read the original article here.