PRODUCT DETAILS

Click an item to expand and learn more

-

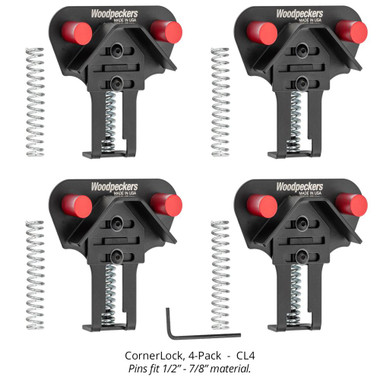

Woodpeckers new CornerLocks spring into action whenever you need two pieces of stock held square to each other. Use them to hold projects in alignment while your install fasteners, apply bar clamps or figure out the next step in your process. They couldn't be easier to use. Just compress the spring and drop the CornerLock over the two pieces. The spring captures your material between a square steel corner and two alignment pins. Just slide the stock into perfect alignment and you're done. Two different springs are provided. The lighter spring is perfect for delicate projects. When components are bigger and you want to make sure things don't move, switch back to the standard springs.

The steel square jaw on the inside of the CornerLock is mounted on a slide. This allows you to work with stock of different thicknesses…up to 1/4" of variation. The jaw automatically slides over to compensate for the difference. You get even pressure on both the thick and thin pieces.

Standard CornerLocks work with material from 1/2" to 7/8". If you work with a lot of thinner material, you can get an optional set of larger alignment pins. These larger pins give you a solid grip on material as thin as 1/4" while still allowing you to grip 3/4" stock. It takes just seconds to change from the standard alignment pins to the thin stock pins.

Of course, nothing says you can only use CornerLocks on corners. They'll work in the middle of a board, too. Align shelves in a cabinet wherever you want them. Play with the spacing all you want with CornerLocks holding the shelf in place while you and your significant other decide on just the right spacing.

Unlike lightweight plastic versions you may have seen on the internet, CornerLocks are built from steel and aircraft-grade aluminum. Each tool is individually formed on our computerized press brake, not molded by the millions. The reference surface isn't a spongy rubber pad, it's a precision-machined anodized aluminum cylinder. This is a tool that will be used on every project, instead of being lost in the back of a drawer.

Like all Woodpeckers products, CornerLocks are precisely machined and carefully inspected in our Strongsville, Ohio, facility just south of Cleveland.

Additional Info

- Holding two pieces of stock square to each other during assembly or construction.

- Keeping projects aligned while installing fasteners, such as screws or nails.

- Assisting in the application of bar clamps to ensure even pressure and alignment.

- Facilitating precise alignment of components during the construction process, especially useful in woodworking and cabinetry.

- Providing adjustable pressure for delicate projects with a lighter spring option, preventing damage to sensitive materials.

- Securing larger, heavier components with a standard spring to ensure they don't move during assembly.

- Accommodating stock of varying thicknesses, thanks to an adjustable steel square jaw, making it versatile for different project requirements.

- Offering a solid grip on thin materials as well as thicker stock by switching out alignment pins, enhancing the tool's adaptability.

- Aligning shelves within a cabinet to desired spacing, proving useful in custom shelving projects and interior renovations.

- Utilizing beyond corners, for instance, in the middle of boards for unique project requirements or creative applications.

- Constructed from durable materials such as steel and aircraft-grade aluminum, ensuring longevity and reliability for all types of projects.

- Precision-machined for accuracy, making it an essential tool in professional woodworking shops and for hobbyists seeking high-quality results.

- Designed and inspected in a facility known for producing high-quality tools, guaranteeing a level of craftsmanship and reliability.

-

-

CornerLock

CornerLock Production Update: CornerLock

Production Update: CornerLock