Best End Mill Bits

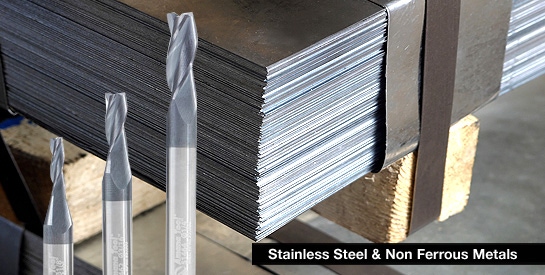

End Mill bits are typically used for metalworking, although they can be (and often are) used on wood. Choose solid carbide to handle the high rotational speeds, specific feed rates, and cutting forces involved in metal milling. An Aluminum Titanium Nitride (AlTiN) coating provides extra wear resistance and allows for faster speed rates with less heat buildup.

Amana end mills are made from their exclusive, ultra-fine micrograin carbide, and feature a 30 degree center-cutting mill end, a corner chamfer (for extra strength), up-cut design and very importantly, a AlTiN Coating.

When cutting stainless steel, cast iron, or even titanium on your CNC machine, these are the bits you want.

Why is it called an End Mill?

Typically, end mill bits cut along the lateral sides of the bit, as opposed to plunging down into the material.

You can cut slots by starting at one end of the material and cutting across, or use an end mill for profiling along the peripheral edge of the material.

These End Mills Take a Plunge!

With their 30 degree center-cutting mill end, and their up-cut design, Amana solid carbide CNC spiral end mills can cut metal both laterally and vertically. So go ahead, take the plunge.

Suitable Materials

The AlTiN coating, along with a few physical attributes (upcut, mill end, corner chamfer, etc.) combine to give you a router bit that can rout and mill steel, stainless steel, even titanium. These router bits are specifically designed for CNC machines, which is a good thing, as you can then accurately control feed rates to match the material being cut.

How Many Flutes Do I Need?

Two flutes provide a good balance between speed of cut and finish quality.

Three or even four flutes are used for a smoother finish, and, for peripheral milling, increased speed rates.

Generally, the more flutes a router bit has, the finer the finish it will produce. This is because the bit makes more cuts per revolution. This also means each flute gets less wear.

However, there's a trade-off: more flutes typically mean more heat and slower material removal because the channels for chip evacuation are narrower. So, in plunge applications, 2 flutes are better.

Fewer flutes typically allow for faster material removal because there's more space for the chips to evacuate. However, the finish might be rougher compared to bits with more flutes.

To sum: Choose 2 flute endmills for efficient vertical plunging, pocketing and slotting operations. 3 and 4 fluted tools offer the promise of improved surface finishes, longer service life and increased feed-rates with peripheral milling applications.

Chamfered Corners for Greater Strength

A typical end mill's number one major wear point will be the corner, especially when making numerous plunge cuts.

By chamfering the corners by 45-degrees, Amana end mills have greater edge strength and extended tool life

.

.

Wide Range of Sizes

This series comes in diameters from 1/16 to 1/2 inch, and a cutting height from 3/16 to 1 inch. (As well as common metric sizes.) Longer bits will have more vibration, so always choose the shortest bit which will do the job.

Still too big? Miniature end mills are designed for micro-applications including signmaking, jewelry making, and more.

Doing a lot of end milling? Get a 4-pack or an 8 piece set!

You can also purchase the same solid carbide with AlTiN coating as a 90 degree V-spiral drill / end mill for grooving and edge-chamfering.

(Jump to 6:15 to see the 51462 End Mill rough out this bald eagle medallion.)