An Essential Guide to Shaper Cutters

The Essential Tool for Industrial Production

If you are involved in production and woodworking on an industrial level, you understand that one big variable to your efficiency of work is the machines and tools found in the shop. If you have ever taken a tour of someone else’s shop, there are two subjects that immediately come up in conversation.

One, current projects being worked on, and two, the machines and tools the shop owner has collected over the years. Aside from the Table Saw, Planer, and Band saw, there is one other machine which deserves just as much attention: the Shaper.

Intermediary Step Between Rough Cut and Hand Work

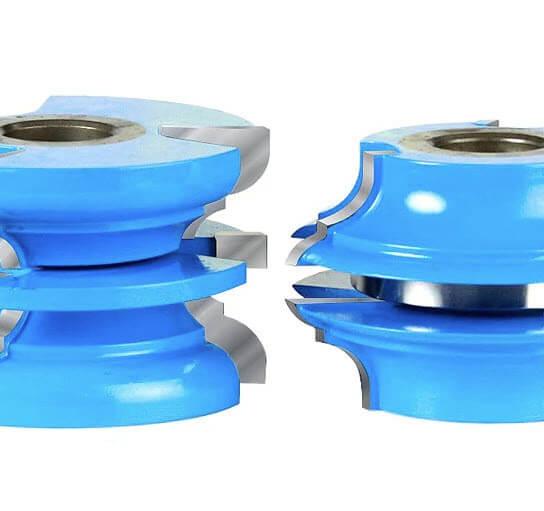

The shaper cutter becomes the intermediary machine used between rough cutting and hand work. This is where your pieces really take shape (excuse the pun). While the shaper itself has limited capabilities, a huge variety of shaper cutters are available on the market to expand your shaper’s capabilities.

The shaper can be used for joinery, straight edge, profiling, molding, window sash, wainscot, paneling, stile and rail, raised panel, door-making, tongue and groove, mission style, cabinet door making, flooring, raised panel shaper cutters and more…

The most beneficial aspect of a shaper and shaper cutters is that you don’t have to purchase an entire set of cutters at one time. When you get to a point where you need a specific profile for a job, you just need to go online and order the specific cutter for that job and it arrives within days.

As a woodworker, you understand that your profits don’t just come from the revenue from the final piece but from the cost savings in overhead as well. So if you’re on a budget, you can purchase on a need-only basis. Over time, your collection of cutters will grow, increasing your repertoire of abilities.

Profiles

The following are some examples of cutter profiles which correlate with what it is used for.

Solid Carbide Insert Knife Door Making

Cost

Shopping around for shaper cutters one can find examples from both sides of the spectrum; lesser quality to high quality. For the most part, these levels of quality also correspond to its cost. There are a few things you should know before purchasing cutters.

First: material; what is the shaper cutter made of? Currently solid carbide or carbide tipped is a great choice. Carbide is extremely hard, keeps its sharp edge and is able to withstand high heat.

Second, purchase from a reputable company. Not only will you receive what was advertised but you will also receive great customer service and accountability if needed.

View the hundreds of Shaper Cutters in stock at toolstoday.com.