Flooring the Opposition

How often do you walk on what looks like a solid hardwood floor, only to realize it’s just a thin veneer? You feel it underfoot — that springy sensation and the telltale slap of floating panels tapping the subfloor with each step.

Another common polished timber floor uses full-thickness boards, but if they’re not tongue and grooved together, each plank is often nailed down in haste, leaving rows of nail holes filled with poorly matched putty.

But what if you have found some beautiful timber, either new or reclaimed, that you’d love to use? The solution is to make your own floorboards — and creating your own tongue and grooves is the way to go. A basic tongue and groove joint can join boards well, but Toolstoday.com offers a more refined flooring router bit set from Amana Tool, endorsed by Lonnie Bird.

This matched set of two flooring router bits is exceptionally well made. I don’t usually notice the fit of the shaft in the router, but these bits were particularly well machined. Many companies overlook the shaft quality, accepting microridges from tooling marks — but these were remarkably smooth and fit perfectly. Smoothness doesn’t cause slippage; lubrication or insufficient contact area does. In fact, ridges can reduce the contact area between the router shaft and the collet.

A smooth shaft maximizes contact and grip. If you doubt this, remember that Formula 1 cars perform best on slick tires in dry weather — more surface contact means better performance.

Beyond the shaft, the overall finish of these bits is excellent: no rough brazing, and high-quality carbide firmly bonded to the base material.

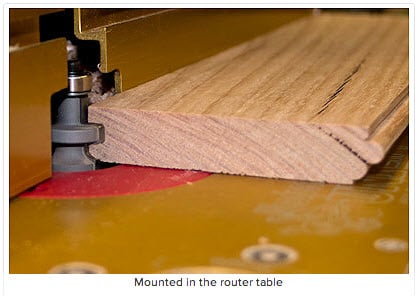

These router bits should be used in a table-mounted router, and a fence is highly recommended. Although the bits have bearings, thinner boards may not engage them fully, so a fence ensures precise alignment. There are two sets available: one for boards 5/8″–3/4″ (the set I have) and another for boards 1/2″–5/8″.

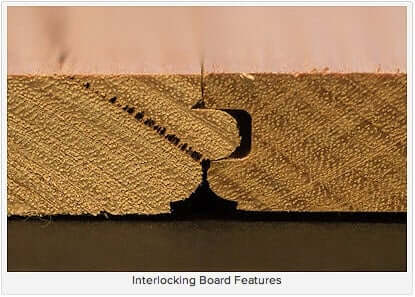

One smart feature is that these bits don’t produce an overly deep groove or an excessively long tongue — there’s no need for a Gene Simmons–length tongue here! Proper proportions mean you won’t risk splitting or breaking off part of the board during installation.

Several thoughtful design details further improve the Amana Tool system:

- Flush fit: Boards come together perfectly flat, minimizing visible gaps and allowing seasonal wood movement with minimal impact.

- Hidden nail slot: A small triangular notch allows you to drive a nail at an angle through the solid wood, securing the board to the joist without interfering with the joint or splitting the tongue.

- Rounded tongue and groove: Rounded edges reduce stress points, minimizing the risk of cracking or breakage.

- Drain cavity: A larger space at the bottom of the joint helps prevent moisture buildup and wicking into the boards.

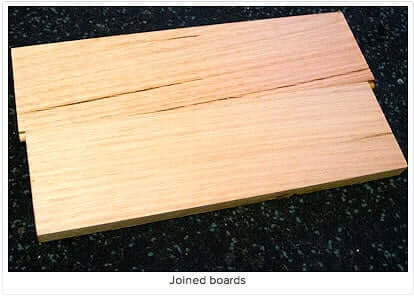

When joined, the boards create a seamless, professional-looking floor where only the natural grain shows the boundary between planks. Using a robust thickness adds to the floor’s longevity and feel. Making your own tongue and groove boards with a quality bit set can save you money and lets you hand-pick the timber for a truly custom floor.

Once again, and unsurprisingly, Amana Tool delivers superb router bits — available from Toolstoday.com.

Originally posted on September 30th, 2012 by Stuart. Read the original article here.