How to Choose and Use a Power Drill

If you're looking to take on some DIY projects around the house, having a power drill in your toolbox is essential. But with so many types of power drills available, how do you know which one is right for you?

We explore the different types of power drills, factors to consider when choosing one, and provide tips on how to use a power drill safely and effectively.

Whether you're a beginner or a seasoned DIYer, this guide will help you make the most out of your power drill.

What Is a Power Drill?

A power drill is a versatile tool used for drilling holes and driving screws in various materials such as wood, metal, and plastic, providing efficiency and precision in DIY projects and professional applications.

It operates by rotating a drill bit at high speed, allowing users to create clean and accurate holes with ease. With a wide range of drill bits available, including twist bits, spade bits, and hole saws, power drills can accommodate different hole sizes and types, catering to a variety of project requirements. The adjustable torque settings on many power drills enable users to control the drilling depth and speed, ensuring optimal results without damaging the material being worked on.

Types of Power Drills

Power drills come in various types, each designed for specific tasks and user preferences, such as cordless drills for portability, impact drivers for versatility, and drill presses for precision drilling.

Corded Drills

Corded drills are reliable power tools that operate through a direct power source, offering consistent performance and unlimited runtime for tasks that require continuous drilling or high power output.

These drills are known for their robust motors that deliver strong torque and high-speed rotations, making them ideal for heavy-duty applications such as drilling through tough materials like concrete, metal, and hardwood.

Their consistent power supply ensures that they maintain a steady drilling speed without the need for recharging or battery replacements, allowing users to work efficiently without interruptions.

Corded drills are renowned for their durability and long operational lifespan, providing reliable performance over extended periods of use.

Cordless Drills

Cordless drills provide the convenience of mobility and freedom from power cords, powered by rechargeable batteries that offer portability and flexibility for users in various settings.

With their battery-powered operation, users can enjoy the flexibility to work in locations without access to electrical outlets. The cordless design allows for easy transportation, making them ideal for on-the-go applications. These drills typically come in compact sizes, ensuring they can be easily stored or carried around. The user comfort is also enhanced as the absence of a cord eliminates the need to constantly position and untangle it during use, providing a seamless drilling experience.

Impact Drivers

Impact drivers are designed to deliver high torque and rotational force, making them suitable for heavy-duty tasks such as metal drilling, screw driving, and fastening applications.

These power tools are equipped with adjustable torque settings, allowing users to customize the power output according to the specific task requirements. This feature not only enhances efficiency but also helps prevent overdriving screws or damaging delicate materials.

Impact driverss excel in demanding applications thanks to their durability and robust construction, ensuring consistent performance even in challenging conditions. With their ability to effectively drill through tough metals, impact drills provide users with a versatile tool for various projects in workshops or construction sites.

Rotary Hammer

Rotary hammers are specialized tools capable of delivering a hammering action in addition to rotation, making them ideal for drilling into tough materials like concrete, brick, and stone.

This dual-action feature allows for more efficient and precise drilling, especially in dense surfaces where standard drills may struggle. The impact drilling capability of hammer drills enables them to power through hard materials with ease, reducing the time and effort required for tasks like installing anchors or creating holes for pipes. Their suitability for masonry work makes them a popular choice among professionals in construction, remodeling, and DIY projects. The ability to switch between regular drilling and hammer drilling modes enhances their versatility, making them valuable tools for various applications.

Drill Press

A drill press is totally different. It's a stationary power tool designed for super-precise drilling of holes. It consists of a motor, a spindle that rotates the drill bit, a table that supports the workpiece, and a depth stop for controlling the drilling depth

Here are some key features of a drill press:

- Accuracy: Because the drill press is stationary and the workpiece is secured in place, it allows for more accurate drilling compared to a handheld drill.

- Versatility: Drill presses can handle a wider variety of drill bit sizes and can be used for drilling holes in various materials, including wood, metal, and plastic.

- Control: The variable speed settings on a drill press allow you to adjust the drilling speed to match the material you are working with.

- Depth control: The depth stop on a drill press allows you to precisely control the depth of the hole you are drilling.

Drill presses are commonly used in woodworking, metalworking, and DIY projects. They are a valuable tool for anyone who needs to drill precise holes on a regular basis.

| Feature | Power Drill | Impact Driver | Rotary Hammer | Drill Press |

|

Primary Function |

Drilling holes in wood, metal, plastic | Driving screws and fasteners | Drilling holes in hard masonry (concrete, brick) | Drilling precise holes in wood, metal, plastic |

|

Impact Mechanism |

No | Yes (rotational force) | Yes (hammering action) | No |

|

Material Handling |

Best for softer materials | Best for driving screws, good for drilling in wood and metal | Best for hard, brittle materials | Best for precise drilling in stationary workpiece |

|

Chuck Type |

Keyed or keyless | Keyless | SDS (special shank) | Keyed |

|

Versatility |

Can drill with various bits, some models have screwdriver | Limited drilling capabilities | Can also chisel in addition to drilling | Limited functionality |

|

Portability |

Highly portable, often cordless options | Portable, typically cordless | Less portable, often corded | Not portable, stationary tool |

|

Precision |

Moderate | Moderate | Lower precision due to hammering | High precision due to stationary design and variable speed control |

|

Price Range |

Most affordable option | Moderate price range | Most expensive option | Moderate price range |

Factors to Consider When Choosing a Power Drill

When selecting a power drill, it is essential to consider various factors such as chuck size for different drill bits, speed and torque settings for versatile applications, ergonomic design for user comfort, and additional features like LED lights for enhanced visibility.

Power Source

The power source of a drill, whether corded or cordless, determines its mobility and runtime, with cordless drills typically featuring rechargeable batteries with varying voltage ratings for different power levels.

Having the freedom to move around without being tethered to a power outlet is a major advantage of cordless drills. The power of a corded drill can be consistent and reliable, ideal for continuous heavy-duty use.

When considering battery voltage for a cordless drill, higher voltage typically equates to more power and torque, allowing for easier drilling into tougher materials. Higher voltage batteries usually mean longer runtimes, although they may also add weight to the drill, affecting its portability and comfort during use.

Chuck Size

The chuck size of a drill determines the range of drill bits it can accommodate, with larger chuck sizes allowing for the use of various drill bit types for different drilling applications and materials.

Having a drill with the right chuck size is crucial for ensuring compatibility with a wide array of drill bits, ranging from standard twist bits to spade bits, hole saws, and even specialty bits like Forstner bits.

Each type of drill bit serves a specific purpose, whether it's drilling through wood, metal, concrete, or other materials. The precision and efficiency of your drilling operations greatly depend on the correct match between the chuck size and the drill bit being used.

Speed and Torque

Speed and torque settings in a drill determine the rotation speed and twisting force applied during drilling, allowing users to adjust these settings for different materials, drilling techniques, and precision requirements.

By varying the speed, users can control how fast the drill bit rotates, impacting the efficiency and smoothness of the drilling process. Higher speeds are often used for softer materials like wood, while lower speeds are preferred for tougher materials like metal or concrete.

On the other hand, adjusting the torque setting determines the amount of twisting force applied, influencing the drill's power and its ability to handle resistance. Fine-tuning these settings not only enhances drilling performance but also increases the versatility and precision of the tool, making it easier to achieve accurate and clean holes.

Ergonomics and Comfort

Ergonomics and user comfort are crucial aspects of a power drill, with features like ergonomic design and a comfortable grip handle enhancing user experience, reducing fatigue, and improving control during extended use.

The design elements of a drill play a significant role in how comfortable and easy it is to operate. A well-thought-out handle that fits nicely in the user's hand can not only reduce strain on the hand and wrist but also enhance overall control and precision. Ergonomic considerations extend beyond just immediate comfort, as they can impact the user's ability to work efficiently over time.

By prioritizing ergonomics in drill design, manufacturers can ensure that their tools are not only effective but also sustainable for long-term usage, promoting user well-being and productivity.

Additional Features

Modern power drills often come with additional features such as built-in LED lights for improved visibility in low-light conditions and keyless chucks that allow for quick and tool-free drill bit changes, enhancing user convenience and efficiency.

These supplementary features not only make tasks easier but also contribute to the overall performance of the power drill. For instance, some models now include adjustable clutch settings that help prevent overdriving screws, making it ideal for different materials.

Ergonomic designs with rubberized grips provide comfort during extended use, reducing hand strain and fatigue. Some advanced drills even feature smart technology like Bluetooth connectivity for monitoring battery life and adjusting settings wirelessly, setting a new standard for convenience in power tool operation.

How to Use a Power Drill Safely and Effectively

Using a power drill safely and effectively involves following proper safety precautions, selecting the right drill bit types for specific materials, and employing correct drilling techniques to achieve accurate and clean results.

Wear Protective Gear

Before operating a power drill, it is essential to wear appropriate protective gear such as safety goggles, gloves, and ear protection to safeguard against potential hazards and ensure personal safety during drilling tasks.

Safety goggles are crucial to shield the eyes from debris and flying particles that may result from drilling. Gloves not only protect your hands from cuts and scrapes but also provide a better grip on the drill, reducing the risk of accidents. Ear protection is necessary to prevent hearing damage due to the loud noise produced by power drills. It is important to secure loose clothing and tie back long hair to avoid entanglement with the drill. Maintaining a clutter-free workspace and following proper operating instructions further contribute to a safe working environment.

Familiarize Yourself with the Drill

Before starting any drilling operation, it is crucial to read the user manual provided by the manufacturer to understand the drill's features, functions, and safety guidelines, ensuring proper usage and optimal performance.

Familiarizing yourself with the user manual not only enhances your understanding of the drill but also allows you to make the most out of its various features for efficient drilling. By exploring the different settings and capabilities of the drill as outlined in the manual, you can achieve precise results on your projects.

The safety instructions provided in the manual are essential for preventing accidents and ensuring your well-being during usage. Taking the time to familiarize yourself with these guidelines can significantly reduce the risk of injuries and damages.

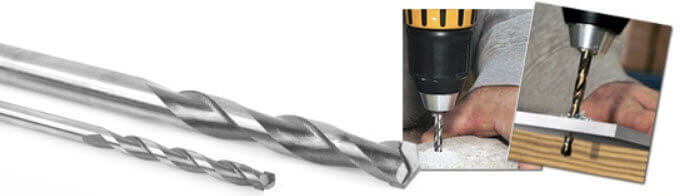

Choose the Right Drill Bit

Selecting the right drill bit for the material and task at hand is essential for achieving precision drilling results, with different drill bit types available for wood, metal, masonry, and other materials.

Whether you are a seasoned DIY enthusiast or a professional contractor, knowing which drill bit to use can make a significant difference in the outcome of your project. Wood requires a different type of drill bit compared to metal or masonry due to variations in hardness and texture. Using the correct bit ensures that you can drill efficiently and with precision, reducing the risk of damaging the material or compromising the structural integrity of your work. Understanding the impact of correct bit selection can enhance both the efficiency and quality of your drilling tasks.

Secure Your Workpiece

Before starting to drill, ensure that the workpiece is securely clamped or held in place to prevent movement or slippage during drilling, maintaining accuracy, and safety throughout the operation.

Securing your workpiece properly not only ensures precise drilling but also minimizes the likelihood of accidents or damage. To achieve consistent drilling depths, it is advisable to use depth stop collars or adjustable drilling guides. These tools help control the depth of the drill bit, allowing you to maintain uniform hole depths effortlessly.

Inspect the drill bit for any damage or wear before starting to ensure efficient drilling and reduce the risk of any unforeseen issues. Always prioritize safety measures to create a conducive environment for successful drilling tasks.

Start Slow and Steady

When using a power drill, start at a low speed and gradually increase the speed based on the material being drilled, utilizing the forward/reverse function as needed for drilling and screwdriving operations.

Variable speed settings are a key feature in power drills, allowing you to adjust the speed to suit different materials or tasks. For precision drilling, starting at a slower speed gives you better control over the drilling process, minimizing the risk of mistakes. When switching to screwdriving, the forward/reverse function comes in handy for driving screws in and out efficiently. By being mindful of speed control and using the right settings for each task, you can achieve optimal results and prolong the life of your power drill.

Maintain Good Posture

Maintaining good posture while using a power drill is essential for reducing strain and fatigue, with ergonomic design features and the drill's weight distribution playing a crucial role in ensuring user comfort and control.

Proper body positioning not only enhances comfort but also reduces the risk of injuries such as muscle strains and back pain that can result from poor posture.

By keeping your back straight, shoulders relaxed, and distributing the weight evenly between both arms, you can minimize the load on specific muscle groups, leading to less fatigue over extended drilling tasks.

Implementing these ergonomic practices not only promotes efficiency in your work but also supports long-term physical health and well-being in the workshop or job site environment.

Keep Your Work Area Clean and Organized

Maintaining a clean and organized work area when using a power drill is essential for safety, efficiency, and precision, with proper drill storage ensuring accessibility and protection for the tool and accessories.

A clutter-free workspace reduces the risk of accidents and injuries by preventing tripping hazards and allowing ample room for maneuvering the drill safely. By keeping a tidy environment, workers can quickly locate necessary equipment, such as drill bits, without wasting time searching through disorganized spaces. It also promotes a more focused mindset, as a neat workspace minimizes distractions and enhances concentration during drilling tasks.

Implementing efficient drill storage solutions, like wall-mounted racks or portable tool chests, not only keeps the workspace tidy but also prolongs the life of the drill by protecting it from damage when not in use.

Practice, Practice, Practice

Improving drilling skills and achieving precision require consistent practice with the power drill, focusing on mastering drilling techniques, handling the tool with confidence, and honing accuracy for various applications.

Regularly practicing with a power drill not only enhances your proficiency but also enables you to fine-tune your technique and ensure precise outcomes. Understanding the intricacies of different drilling methods and how to optimize them can significantly boost your efficiency.

By continuously refining your skills, you develop a keen eye for detail and the ability to tackle diverse drilling tasks with ease. Embracing the learning process and seeking improvement grants you a competitive edge in the field, allowing you to deliver superior results consistently.

Frequently Asked Questions

1. What should I consider when choosing a power drill?

When choosing a power drill, you should consider the drill's power source (corded or cordless), its speed and torque, its size and weight, and the type of projects you will be using it for.

2. How do I determine the right size and weight for my power drill?

The size and weight of a power drill should be determined by the type of projects you will be using it for. For smaller projects, a lighter and more compact drill may be suitable, while larger projects may require a heavier and more powerful drill.

3. Can I use a cordless power drill for heavy duty projects?

Yes, you can use a cordless power drill for heavy duty projects. However, it is important to choose a drill with a high voltage and torque to ensure it can handle the task efficiently.

4. Is it necessary to have different drill bits for different materials?

It is recommended to have different drill bits for different materials to ensure the best results. For example, a wood drill bit may not work well on metal or concrete, and vice versa.

5. How do I safely use a power drill?

To safely use a power drill, always read the instruction manual carefully and wear appropriate safety gear such as goggles and gloves. Make sure the drill is turned off and unplugged when changing drill bits or making adjustments.

6. Can I use the same power drill for drilling and driving screws?

Yes, most power drills have a drill and driver mode that allows you to use the same drill for both drilling and driving screws. Just make sure to adjust the torque setting accordingly for each task.