Router Bit Bearings for Enhanced Precision & Control

Understanding the role of bearings in router bits is crucial for any woodworker aiming for high precision and control in their projects. This guide covers the types, benefits, and selection tips for router bit bearings, ensuring your tools maintain top performance.

Introduction to Router Bit Bearings

Bearings are integral to router bits, reducing friction and enhancing tool precision. High-quality bearings ensure smooth operations and extended tool life by minimizing wear and efficiently dissipating heat.

Function and Mechanism of Bearings

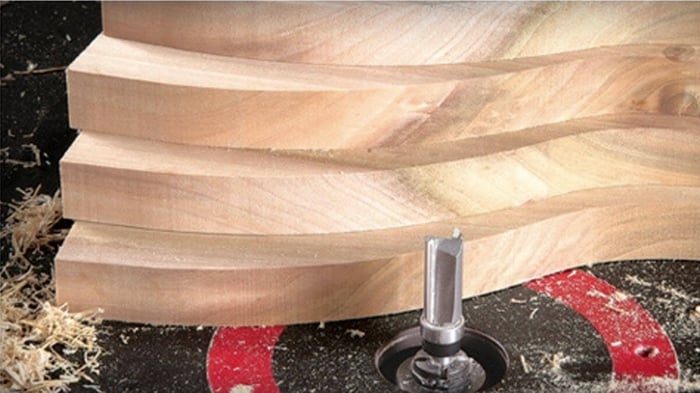

Bearings support the rotating shaft of router bits, facilitating smooth and efficient cutting actions. They reduce operational stress and prevent inaccuracies, crucial for achieving clean and precise cuts in woodworking.

Benefits of Using Bearings in Router Bits

Integrating bearings into router bits enhances tool efficiency, reduces heat build-up, and ensures consistent performance. This results in prolonged tool life and superior craftsmanship in woodworking projects.

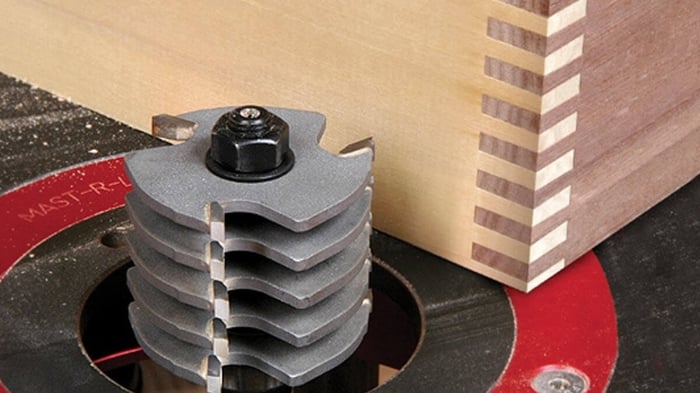

Bearings are commonly used in flush trim router bits, as well as other profiling bits where the bit follows a path along the edge of the workpiece, such as:

Different Types of Bearings in Router Bits

Router bits commonly use ball bearings for smooth, detailed work and roller bearings for tasks requiring high durability and load capacity. Choosing the right type depends on the specific needs of your woodworking projects.

Comparison: Ball Bearings vs. Roller Bearings

Ball bearings provide precise movement ideal for intricate detailing, while roller bearings offer superior strength and load capacity, making them suitable for more intensive woodworking tasks.

Selecting the Right Bearing for Your Project

The choice of bearing should align with your project's demands—consider factors like load capacity, rotational speed, and the bearing's material. Ensure compatibility with your router bit to achieve the best results.

Key Factors to Consider

Evaluate the requirements of your woodworking project, including the necessary precision, speed, and durability. Match these requirements with the bearing's capabilities to optimize tool performance and project outcomes.

Maintenance Tips for Router Bit Bearings

Regular cleaning and proper lubrication extend the life of your bearings and maintain tool efficiency. Replace bearings promptly when signs of wear appear to avoid tool damage and maintain work quality.

Effective Cleaning and Replacement Strategies

Maintain a regular maintenance schedule to clean and inspect your bearings. Replace worn bearings to prevent tool failure and ensure consistent performance in your woodworking projects.

Frequently Asked Questions

What is the Function of a Bearing in a Router Bit?

A bearing guides the router bit to maintain precise cut depth and stability, essential for high-quality woodworking finishes.

When to Replace Router Bit Bearings?

Replace bearings when you notice decreased performance or increased noise and vibration, ensuring uninterrupted tool operation and precision.