Top FAQs About Circular Saw Blades

Circular saw blades are an essential tool for a wide range of cutting tasks, from rip cuts to crosscuts and everything in between. Whether you're a professional contractor or a DIY enthusiast, understanding the different types of circular saw blades and how to choose the right one for your project is crucial.

In this comprehensive guide, we will explore the various types of circular saw blades, the factors to consider when selecting the right blade for your needs, and essential tips for care and maintenance. We also address (very important!) safety precautions. If you've ever wondered about the different types of circular saw blades, when to replace them, or how to ensure their longevity, we've got you covered.

Let's delve into the world of circular saw blades and equip you with the knowledge you need for successful cutting projects.

What Is A Circular Saw Blade?

A circular saw blade is a cutting tool specifically designed for woodworking applications, capable of making precise and efficient cuts in various wood materials.

It is crafted with sharp teeth around its edge that swiftly bites into the wood, creating smooth and clean cuts. Circular saw blades come in different sizes and tooth configurations, allowing them to cut through softwoods like pine and cedar, as well as hardwoods such as oak, maple, and mahogany. They are essential for projects like framing, decking, and furniture making, providing woodworkers with the versatility and accuracy needed for professional-quality results.

What Are The Different Types Of Circular Saw Blades?

Circular saw blades come in a variety of types, each tailored to specific wood cutting requirements and techniques, providing versatility and precision in woodworking applications.

They can be classified based on the number of teeth, blade material, and tooth design. For example, rip blades with fewer teeth are ideal for making long, parallel cuts along the wood grain, while crosscut blades with more teeth provide clean and precise cuts across the grain.

There are specialty blades such as dado blades for making wide grooves and rabbeting blades for creating recessed edges. Understanding the capabilities and ideal usage scenarios for each type of circular saw blade is essential for achieving optimal results in woodworking projects.

What Are Rip Blades?

Rip blades are designed for making long, parallel cuts along the wood grain, ideal for tasks such as dimensioning lumber and creating straight edges in woodworking projects.

They feature fewer teeth compared to crosscut blades, with larger gullets for efficient chip removal and reduced heat buildup. This design helps prevent binding and burning, making them well-suited for the repetitive nature of rip cuts. As a result, they are widely used in table saws and circular saws for effectively cutting through hardwood and softwood, enhancing the accuracy and smoothness of the cut edges.

Woodworkers rely on rip blades to achieve precise wood dimensions and maintain a high level of craftsmanship in their projects.

What Are Crosscut Blades?

Crosscut blades are optimized for making perpendicular cuts across the wood grain, delivering clean and accurate results for tasks such as sawing boards and creating precise wood joints in woodworking projects.

These blades are designed with a series of evenly spaced teeth that are shaped to cleanly slice through the wood fibers, reducing splintering and tear-out commonly associated with crosscutting. Their unique tooth geometry and alternating bevel angles facilitate smooth and efficient cutting, ensuring minimal resistance and strain on the power tool. When used with a suitable saw, crosscut blades enhance the blade's ability to make precise, splinter-free cuts, making them invaluable for woodworkers who prioritize the quality and precision of their woodworking endeavors.

What Are Combination Blades?

Combination blades are versatile options that can perform both rip cuts and crosscuts effectively, offering convenience and flexibility for various woodworking tasks without the need for frequent blade changes.

They are designed to handle different types of wood, from softwoods to hardwoods, delivering clean and precise cuts. This dual-purpose design makes them ideal for DIY enthusiasts, craftsmen, and professional woodworkers alike, as they can tackle a wide range of projects with ease. Their multifunctional capabilities also make them a cost-effective choice, saving both time and money by eliminating the necessity for separate blades for different cutting tasks. Whether it's creating joinery, building furniture, or making cabinetry, combination blades are a valuable tool to have in your woodworking arsenal.

What Are Plywood Blades?

Plywood blades are engineered to deliver smooth and tear-free cuts specifically tailored for plywood and veneer materials, ensuring precise and clean results in woodworking projects involving these materials.

They are designed with high tooth-count and special tooth geometry to minimize chipping and splintering, which are common challenges when cutting plywood. The tooth configuration and hook angles are optimized to efficiently cut through the layers of plywood, providing exceptional control and reducing the risk of material tear-out.

This specialized construction ensures that the blades maintain their sharpness and cutting precision for extended periods, offering reliability and consistent performance in woodworking applications. The use of high-quality materials in the manufacturing process enhances the durability and longevity of plywood blades, making them a valuable investment for woodworkers seeking professional-grade results in their plywood cutting tasks.

What Are Dado Blades?

Dado blades are designed for creating grooves and dadoes in wood, offering adjustable widths and depth settings for precise joinery and groove-cutting requirements in woodworking projects.

These versatile blades are capable of cutting grooves of varying widths, making them ideal for tasks like cabinet making, shelving, or creating snug-fitting joints for bookcases and drawers. Their adjustable nature allows woodworkers to customize the size of the dadoes, ensuring a perfect fit for the parts being connected. This level of precision and flexibility makes dado blades an essential tool for fine woodworking, where accuracy and sturdy joinery are paramount.

What Are Miter Blades?

Miter blades are tailored for making miter cuts at precise angles, offering accuracy and consistency for creating bevels, miters, and angled cuts in woodworking projects with ease and precision.

They are designed with specialized tooth configurations and angles to ensure clean and smooth cuts in various types of wood, allowing woodworkers to achieve seamless joints and precise corner fittings. Miter blades are integral for creating intricate and seamless frames, moldings, and trims. Their ability to handle complex cutting tasks with efficiency makes them indispensable for professionals and hobbyists alike in the woodworking industry."

What Are The Factors To Consider When Choosing A Circular Saw Blade?

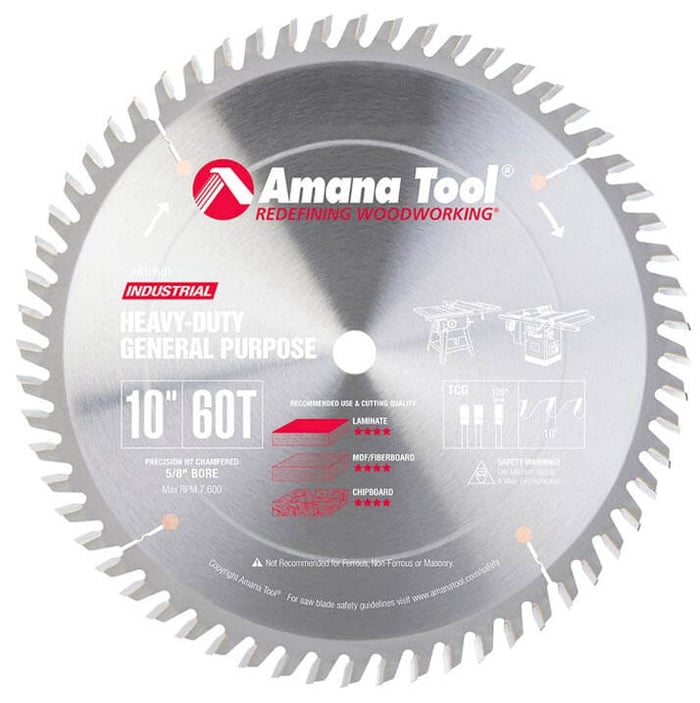

When selecting a circular saw blade, several key factors need to be considered, including the blade size, number of teeth, material composition, kerf size, and RPM rating, to ensure optimal performance and cutting precision in woodworking tasks.

The blade size determines the depth of the cut, with larger blades suiting thicker materials. The number of teeth affects the smoothness of the cut, with more teeth yielding finer finishes. The material composition of the blade impacts its durability and suitability for specific woodworking applications.

Considering kerf size and RPM rating is crucial for minimizing waste and ensuring compatibility with the saw's speed, respectively. Regular maintenance, such as cleaning and sharpening, contributes to prolonged blade lifespan and consistent cutting performance.

What Size Blade Do I Need?

The size of a circular saw blade directly impacts its cutting capacity and compatibility with different saw models, requiring careful consideration to ensure proper fit and performance for woodworking applications.

The blade size influences the depth and precision of cuts, affecting the efficiency and quality of woodworking projects. It is crucial to match the blade size with the specific tasks at hand, such as cross-cutting or ripping, to achieve optimal results. Understanding the saw's limitations and recommended blade sizes is essential to prevent accidents and maximize safety.

Each blade size has its unique advantages, catering to various woodworking needs, from intricate detailing to large-scale construction. Effective utilization of appropriate blade sizes contributes significantly to achieving flawless and professional woodworking outcomes.

How Many Teeth are on a Saw Blade?

The number of teeth on a circular saw blade influences its cutting speed, finish quality, and material adaptability, making it a critical factor in determining the blade's effectiveness for different woodworking requirements.

By varying the tooth count, woodworkers can achieve specific performance attributes tailored to their projects. A higher tooth count generally results in smoother cuts with finer finish quality, making it ideal for materials like plywood or melamine. On the other hand, blades with fewer teeth offer faster cutting speeds and are more suitable for rougher materials such as softwood.

The tooth configuration, like alternate top bevel (ATB) or triple chip grind (TCG), further enhances the blade's performance for crosscuts, rip cuts, or combo cuts, ensuring optimized results across various woodworking tasks.

What are Circular Saw Blades Made Of?

The material composition of a circular saw blade, such as carbide-tipped or high-speed steel, directly affects its durability, cutting precision, and suitability for specific wood types and cutting techniques in woodworking applications.

Carbide-tipped blades are known for their exceptional durability and sharpness, making them well-suited for cutting through hardwoods and abrasive materials. On the other hand, high-speed steel blades offer excellent cutting precision and are suitable for working with softer woods and general-purpose cutting tasks. Selecting the right blade material is crucial for optimizing the blade's performance and achieving precise, clean cuts in woodworking projects, ultimately impacting the overall quality of the finished workpieces.

What is Kerf Size?

The kerf size of a circular saw blade determines the width of the cut and the material waste generated, influencing the efficiency and accuracy of woodworking operations, making it an important consideration for blade selection.

Optimizing the kerf dimensions allows woodworkers to achieve finer cuts, as smaller kerf sizes result in reduced material waste and thinner cuts, enhancing precision. Smaller kerf sizes also contribute to improved cutting efficiency, as they require less power to drive the blade through the wood, thereby increasing productivity.

Understanding the impact of kerf size on woodworking processes empowers craftsmen to select the most suitable saw blades for their specific projects, ensuring both quality and cost-effectiveness in their woodworking endeavors.

What is RPM Rating?

The RPM rating of a circular saw blade denotes its maximum rotational speed, affecting cutting performance, heat generation, and safety considerations, making it a crucial factor in choosing the right blade for woodworking tasks.

An appropriate RPM rating ensures efficient cutting, as the speed directly influences how smoothly and cleanly the blade can slice through wood. Too high an RPM can generate excessive heat, leading to potential burn marks or even wood combustion, while too low an RPM may cause the blade to struggle and splinter the wood.

By understanding the RPM rating in the context of woodworking applications, professionals can make informed decisions to optimize their blade's performance and enhance safety during cutting operations.

How Do I Know When To Replace My Circular Saw Blade?

Knowing when to replace a circular saw blade involves monitoring its cutting performance, examining wear indicators, and addressing any signs of damage or deterioration, ensuring safe and efficient operation in woodworking tasks.

This proactive approach to maintenance is essential for ensuring the quality of cuts and preventing potential safety hazards. Key indicators of blade wear include:

- Reduced cutting speed

- Burning or scorching of wood

- Rough or uneven cuts

- A dull appearance on the blade's cutting edges

Any chipping, warping, or missing teeth should also prompt immediate attention.

Regular inspection and timely replacement of worn or damaged blades contribute significantly to the longevity of woodworking tools and the precision of their results.

How Do I Properly Care For My Circular Saw Blade?

Proper care for a circular saw blade involves regular cleaning, sharpening as needed, and storage in a suitable environment to maintain cutting efficiency, extend blade life, and ensure safe operation in woodworking projects.

Regular cleaning of the saw blade is crucial to prevent resin and pitch buildup, which can hinder the cutting performance. This can be achieved by using a blade cleaning solution and a wire brush to remove debris.

When it comes to sharpening, it's important to use a specialized sharpening tool to maintain the blade's sharpness. Storing the blade in a dry area and using protective covers can prevent corrosion and damage. By following these maintenance practices, the circular saw blade's longevity and cutting capabilities can be preserved.

What Are The Safety Precautions When Using Circular Saw Blades?

Employing safety precautions when using circular saw blades is crucial to minimize risks of kickback, blade binding, and personal injury, requiring adherence to proper handling, protective gear, and operational guidelines in woodworking activities.

It is essential to prioritize the use of safety goggles to protect the eyes from potential debris, and ear protection to minimize the effects of loud noise emitted by the blade. The use of appropriate clothing, including gloves and non-slip footwear, is crucial to prevent accidental slips and cuts.

Adhering to operational safety guidelines involves ensuring that the blade is properly installed and secured, and the workpiece is adequately supported to avoid unexpected movements while cutting.