PRODUCT DETAILS

Click an item to expand and learn more

-

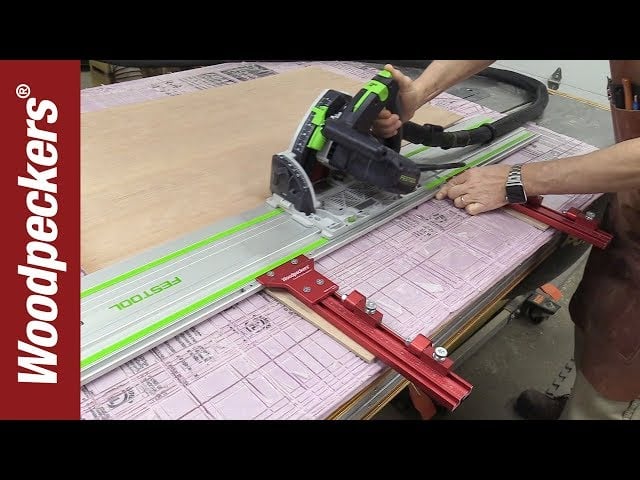

Everyone who has wrangled a full sheet of plywood around a table saw immediately recognizes the advantages of track saws for breaking down sheet goods. Keeping the unwieldy sheet stationary and moving the saw down a precision-made rail makes a lot of sense, but how do you get two (or more) pieces to come out exactly the same width? Just like the rip fence on a table saw, Woodpeckers Parallel Guide System takes measuring and marking out of the equation and uses a physical reference to ensure your last cut is exactly the same as your first. The Parallel Guide System locks onto your Festool, Makita, Milwaukee or Triton guide rail and instantly aligns the cutting line parallel to, and a specific distance from, the edge of your stock.

The Parallel Guide System starts with Woodpeckers Dual Purpose Track. The T-track connects to your saw’s guide rail with a precision-machined bracket that locks in square and secure. With two T-tracks locked to your guide rail, all you have to do is set the zero side-play flip stops to the same dimension, position the stops on the edge of your work and make your cut. Repeat as often as needed…every piece will be exactly the same.

The Parallel Guide System shines when working on large cabinet or furniture panels, but what about smaller pieces? We’ve got that under control, too. Add the Narrow Stock Guides, use the scale on the edge instead of the top, and now you can rip stock from 10-1/2" down to just a fraction of an inch. This feature is really great when you’re on a job site without a table saw and need to make some frame stock immediately, or if your shop space is so limited a table saw is out of the question.

The T-tracks come in sections. Use all of them or just the ones you need. Fully assembled, you can rip up to 52" – well beyond the center of a sheet of plywood. But, when working normal cabinet components, you’ll only need a couple sections assembled. The ends are precisely cut to ensure the connected sections are perfectly straight and the scale calibrations are accurate.

This former OneTIME Tool is now part of our permanent product line-up. Like all Woodpeckers products, the Parallel Guide System is proudly machined and carefully inspected in Strongsville, Ohio manufacturing facility, just south of Cleveland.

Additional Info

- Breaking down large sheets of plywood into smaller, manageable pieces without needing to move the material around a table saw

- Ensuring consistent width of multiple pieces cut from the same sheet of material, ideal for projects requiring precision such as cabinetry or furniture making

- Quickly adjusting for cuts of varying widths without the need for extensive measuring and marking, saving time on project setups

- Making precise cuts on narrow stock, useful for creating frame stock on a job site or in workshops with limited space

- Adapting to different guide rail brands, offering flexibility for users who already own Festool, Makita, Milwaukee, or Triton systems

- Achieving long rip cuts up to 52 inches, suitable for large project components or breaking down oversized panels

- Maintaining straight and accurate connections between T-track sections, ensuring reliable calibration and cut precision across the entire length of the guide system

- Utilizing in small workshop spaces where a traditional table saw setup is not feasible, enhancing the versatility of the work environment

Read More

-

-

Download Manual Instructions

Download Manual Instructions Parallel Guide System

Parallel Guide System Repeatable Rip Cuts with Track Saw

Repeatable Rip Cuts with Track Saw This Track Saw Accessory Might Replace Your Table Saw | Deep Dive

This Track Saw Accessory Might Replace Your Table Saw | Deep Dive