Choosing the Right Foam Cutting Router Bits for Your Project

Foam cutting router bits are essential tools for projects involving foam materials.

Different types of router bits are available, including straight, spiral, ball end, V-groove, round nose, and cove. It's crucial to choose the right one based on factors like foam type, desired cut, size, and shape.

We discuss the importance of foam cutting router bits, the available types, factors to consider when choosing the right one, and how to use them properly for optimal results.

Explore everything you need to know about foam cutting router bits!

What Are Foam Cutting Router Bits?

These bits are specialized tools designed for shaping and cutting foam materials with precision and efficiency. These router bits are crucial for achieving clean cuts and edge quality in various woodworking and DIY projects.

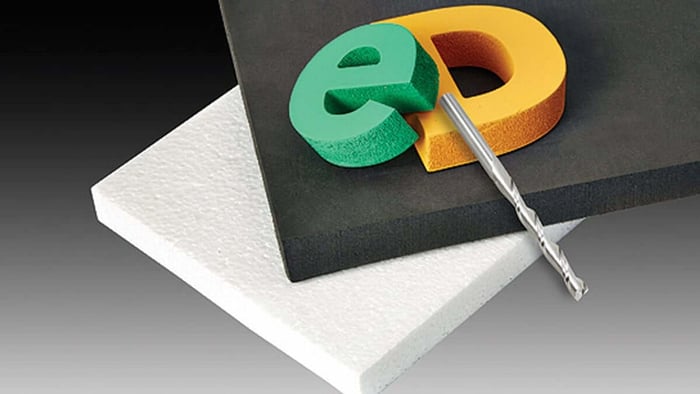

They are typically constructed with high-quality carbide or high-speed steel materials to ensure durability when working with soft and delicate foam materials. The sharp flute designs on these router bits help in maintaining accuracy and producing smooth finishes on foam surfaces. There are different types of foam cutting router bits available in the market, including straight bits for general shaping, spiral upcut bits for making deep cuts without tearing the foam, and ball nose bits for creating curved designs. Each type serves specific purposes and allows for versatile applications in foam cutting projects.

Why Are Foam Cutting Router Bits Important for Your Projects?

These bits play a vital role in woodworking and crafting projects as they provide the necessary precision and tool control required for shaping foam materials effectively. Choosing the right foam cutting router bits can significantly enhance the quality and outcome of your projects.

These specialized router bits are designed to handle the unique properties of foam materials, ensuring clean cuts with smooth edges.

By efficiently removing excess material, foam cutting router bits help craft intricate designs and detailed shapes with ease.

The use of high-quality router bits not only improves the edge quality of the finished products but also ensures their durability over time, making them a reliable choice for a wide range of woodworking applications.

What Are the Different Types of Foam Cutting Router Bits?

There are various types of foam cutting router bits available to cater to different cutting needs and applications. These include straight, spiral upcut, spiral downcut, compression, ball nose, V-groove, and engraving router bits.

Each type of foam cutting router bit has its unique characteristics that make it suitable for specific tasks. Straight router bits are commonly used for general foam cutting, providing clean and precise cuts. Spiral upcut bits are ideal for efficient material removal due to their upward spiral design, while spiral downcut bits give smoother finishes on the foam surface. Compression bits excel in cutting denser foam materials, offering decreased chipping and tear-out. Ball nose bits are great for creating curved surfaces and intricate designs, while V-groove and engraving bits are perfect for detailed or decorative foam carving projects.

What Factors Should You Consider When Choosing Foam Cutting Router Bits?

When selecting bits, it is essential to consider factors such as the material of the foam, the type of cut needed, the size and shape of the foam, as well as the speed and power capabilities of the router being used. These considerations ensure optimal performance and desired results.

Matching the specifications of the router bit with the foam material properties is crucial for achieving efficient and precise cutting. Different foam materials have varying densities, strengths, and textures, requiring specific router bit configurations to cut through them effectively.

Understanding the project requirements, whether it involves intricate designs or straight cuts, helps in selecting the appropriate router bit profile. By aligning these factors, users can enhance the cutting process, minimize material wastage, and achieve smooth, clean cuts in their foam projects.

How Do You Properly Use Foam Cutting Router Bits?

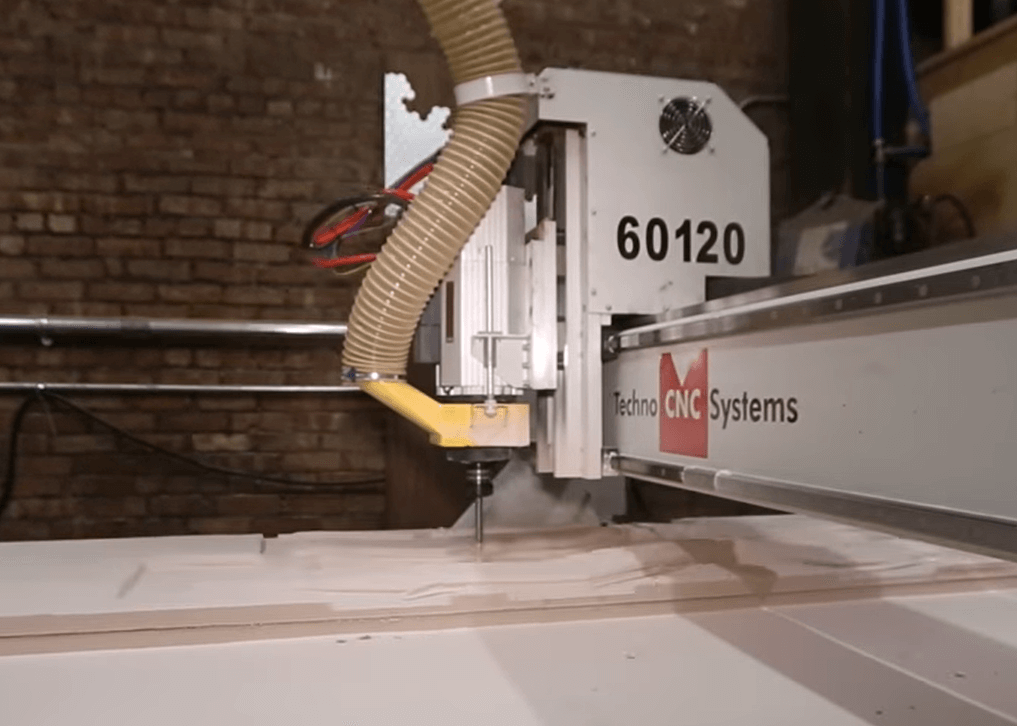

Proper usage of foam cutting router bits involves securing the foam material, selecting the appropriate bit type, adjusting the router speed, making multiple passes for depth control, and cleaning the bit after use to maintain its sharpness and cutting performance.

When securing the foam material, ensure it is firmly in place using clamps or other suitable methods to prevent movement during cutting. Choose the right bit based on the desired cutting outcome; for intricate designs, a smaller diameter bit is preferable, while larger bits are suitable for straight cuts. Adjust the router speed according to the type of foam being cut; lower speeds work well for denser foam, while higher speeds are more efficient for softer foam. Proper chip removal is crucial - use a vacuum or compressed air to clear away debris for precise cuts.

Secure the Foam

Before starting the cutting process, it is essential to securely fasten the foam material to prevent any movement or vibrations during routing. This ensures stability and accuracy in the cutting operation, resulting in consistent and clean cuts.

One effective method for securing foam materials when using router bits is to use clamps or vice grips to hold the material firmly in place. Double-sided tape or adhesive can be utilized to attach the foam to a stable work surface, providing extra support.

Another technique is to create a custom jig or fixture that securely holds the foam in position, allowing for precise and repeatable cuts. Ensuring proper fixation not only enhances safety but also improves the overall quality of the finished product.

Choose the Appropriate Bit

Selecting the right foam router bit based on the desired cut style, foam material properties, and project requirements is crucial for achieving precise and clean cuts. Choose the bit type, diameter, and flute design that best suits the cutting task at hand.

Different types of foam cutting router bits are available in various configurations, ranging from straight bits for standard cuts to spiral bits for more intricate designs. The diameter of the bit plays a significant role in determining the cutting depth and the overall accuracy of the cut. The flute design of the bit affects chip evacuation and heat dissipation during the cutting process. It's essential to match the specifications of the router bit with the specific cutting needs to ensure optimal tool performance and high-quality results.

Adjust the Router Speed

Optimizing the router speed according to the foam material type, bit diameter, and cutting depth is essential for achieving clean and efficient cuts. Adjusting the router's rotation speed ensures proper chip evacuation, minimal heat buildup, and improved cutting precision.

By understanding the material characteristics and cutting requirements, you can prevent issues such as material melting, burning, or tool damage during the cutting process. When working with softer foams, lower rotation speeds are recommended to avoid melting or distortion, while denser foams may require higher speeds for efficient cutting.

It's crucial to find the balance that allows for smooth cutting without compromising the structural integrity of the foam. Experimenting with different speeds and monitoring the cutting process closely can help determine the optimal rotation speed for each specific foam type and cutting task.

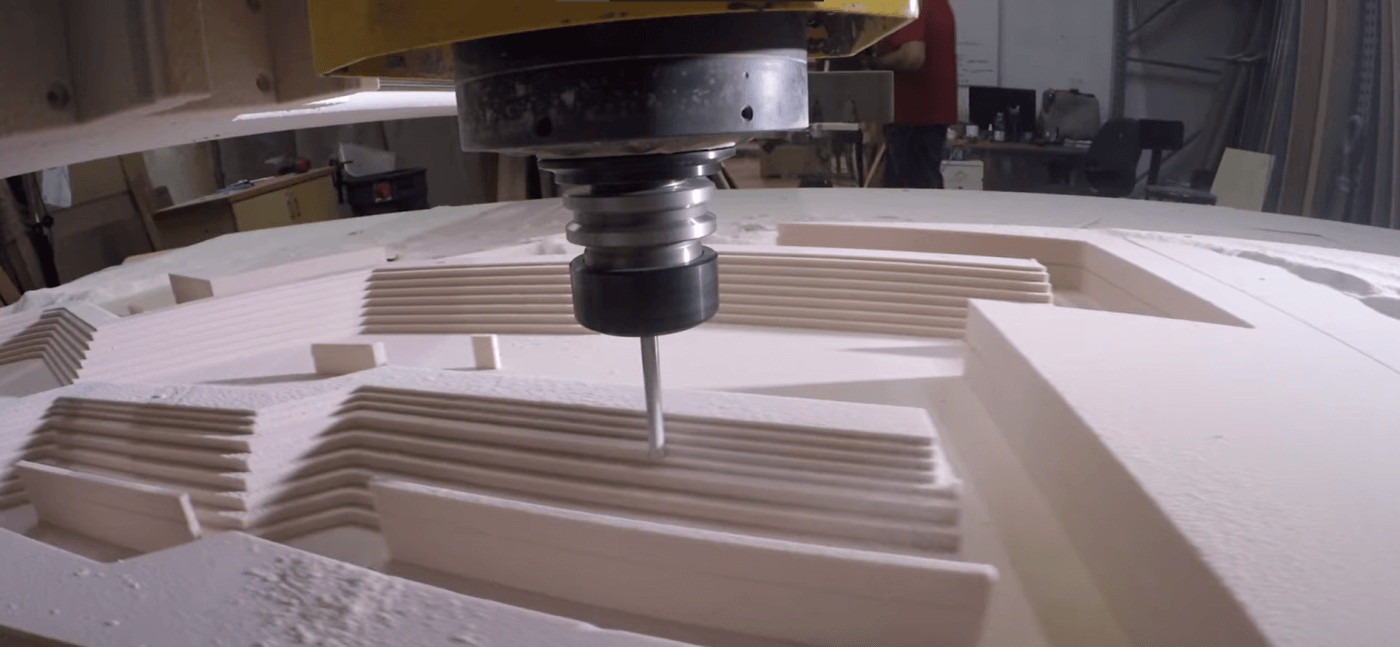

Make Multiple Passes

For achieving precise cuts and consistent depths in foam materials, it is advisable to make multiple passes with the router bit at incremental depths. Gradually increasing the cutting depth ensures control, reduces stress on the bit, and maintains cutting accuracy.

Through the process of making multiple passes, the material removal becomes more uniform, resulting in smoother finishing and minimizing the risk of tearing or uneven cuts.

To determine the ideal number of passes and depth increments for different foam densities, it is essential to consider the specific characteristics of the foam being used. Lighter density foams may require more passes at smaller depth increments, while denser foams may tolerate fewer passes at larger depth increments. Adjusting the feed rate in conjunction with multiple passes can further enhance cutting precision and efficiency.

Clean the Bit After Use

Proper maintenance of foam router bits involves cleaning the bit after use to remove any debris, adhesives, or residue that may accumulate during cutting. Regular cleaning preserves the sharpness and cutting performance of the bit, ensuring longevity and consistent results.

After each use, it is advised to carefully inspect the router bit for any signs of buildup, especially in hard-to-reach crevices. Utilizing a gentle brush or compressed air can effectively dislodge stubborn particles. Soaking the bit in a specialized cleaner can help dissolve any residues or adhesives that have adhered to the cutting edges. It's crucial to ensure that the bit is completely dry before storage to prevent rusting or corrosion.

By practicing these post-cutting cleaning techniques, users can significantly extend the lifespan and optimize the cutting efficiency of their foam cutting router bits.

Frequently Asked Questions

What are foam cutting router bits and why do I need them for my projects?

Foam cutting router bits are specialized tools designed specifically for cutting and shaping foam materials. They are necessary for projects that involve working with foam as they provide clean and precise cuts, making your projects look more professional and polished.

What factors should I consider when choosing the right foam cutting router bits for my projects?

There are a few key factors to consider when selecting foam cutting router bits, such as the type of foam you are working with, the thickness of the foam, the shape and size of the cuts needed, and the type of router bit shank your router accepts.

What are the different types of foam cutting router bits available and which one is best for my project?

There are three main types of foam cutting router bits: straight, spiral, and ball-nose. Straight bits are best for making straight cuts, while spiral bits are ideal for creating more intricate designs. Ball-nose bits are great for 3D carving and smoothing out edges. The best type for your project will depend on the specific cuts and designs you need to make.

Can I use regular router bits for cutting foam instead of specialized foam cutting router bits?

While it may be tempting to use regular router bits for cutting foam, we highly recommend using specialized foam cutting router bits. Regular router bits are not designed for working with foam and may result in rough, messy cuts that could ruin your project.

How do I know if my router is compatible with foam cutting router bits?

Most routers have a universal collet that can accept both 1/4" and 1/2" shank bits. However, it's always best to check your router's manual or contact the manufacturer to confirm compatibility before purchasing foam cutting router bits.

How do I maintain and prolong the lifespan of my foam cutting router bits?

To keep your foam cutting router bits in top condition, it's important to clean them after each use and store them in a dry, cool place. It's also recommended to use a lubricant when cutting foam to reduce friction and prevent overheating. Lastly, make sure to replace your router bits when they become dull to ensure clean and accurate cuts.