Choosing the Right Router Bit for Your CNC

Listen to article

Audio generated by DropInBlog's Blog Voice AI™ may have slight pronunciation nuances. Learn more

No matter what project you’re working on, we have the right CNC router bit for you!

4 Things to Consider When Choosing a CNC Router Bit

- The first thing to consider is the size of the shank your spindle can accept. We offer bits that range from 1/8″ – 3/4″ in shank size. The larger the shank size the more stable the bit will be. Smaller CNCs, like the Shapeoko or X-Carve, utilize trim routers as the spindle; trim routers can only accept up to 1/4″ shank bits, so you will need to be sure any bit you're looking at doesn’t have a shank larger than that.

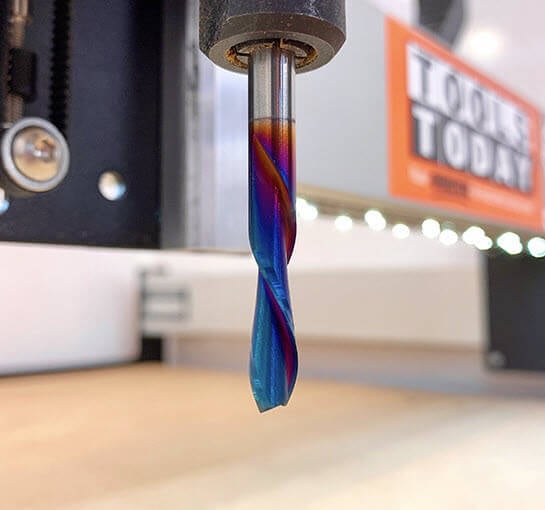

- Second thing to consider is the type of material you are wanting to cut. Most of our bits are able to cut many different types of material, but, like anything, certain bits handle each material better than others. For cuts in wood the Spektra™ coated downcut endmills are an excellent choice to give clean cuts on the top of the material and perfectly clean pockets (we will discuss the different styles of bits in a future post). For clean cuts in plastic the Spektra™ spiral ‘O’ flute bits are a great choice. Aluminum cuts easily using the ZrN coated spiral ‘O’ flute bits and cutting composites are cut using the honeycomb/composite bits.

- Third is the level of detail in the project you’re wanting to make. The diameter of each bit will determine the level of detail you can achieve in a design. There are some trade offs, the smaller the diameter bits cannot run as fast as larger diameters and will take longer to cut; while larger diameter bits can cut very quickly, they cannot achieve the same level of detail. For cutting text and other detailed designs in wood, v-groove and engraving bits are an amazing option. These bits come in a wide range of sizes, and can achieve very fine details and some can carve large areas at the same time both quickly and cleanly. See our “Degrees of a V-Groove” blog post for help selecting the right size

- Fourth is to consider buying your bits in sets. From our basic starter set to our master collection, AMS-CNC-60 pictured above, we offer a wide range of sets for all price points and levels of experience with a CNC. Save money by buying your bits in sets like these at discounted prices vs buying each bit individually.

If you are just starting out with a hobby style CNC I would highly recommend starting with the, pictured above, AMS-119 set. This set has 3 bits that can tackle 80% of the projects you’re going to want to make and is a great set to get you started at an affordable price!

In conclusion, we hope this has provided you with information about how to select the right bit for your CNC, material type and project. We encourage everyone to take a look at the large lineup of bits we offer, read the reviews and give one of them a try, you won’t be disappointed.