4 Ways to Make Rabbet Joints

Rabbet joints are a fundamental aspect of woodworking, offering strength, versatility, and concealed joinery for a variety of projects. In this comprehensive guide, we'll delve into the art and science of rabbet joints, exploring their different types, the tools needed for crafting them, and their advantages and disadvantages.

From understanding how rabbet joints are made to recognizing their applications in woodworking, this article will equip you with the knowledge and insights to elevate your woodworking skills. Whether you're a seasoned woodworker or just starting out, understanding the intricacies of rabbet joints is essential for mastering the craft.

What Is a Rabbet Joint?

Rabbet joints are a fundamental element in woodworking and joinery, serving as a crucial technique where two pieces of wood are joined together to create a seamless and sturdy connection.

They play a vital role in enhancing the structural integrity of furniture, cabinetry, and other woodworking projects. By creating a secure and snug fit, rabbet joints contribute to the overall stability and durability of the final piece. They offer design flexibility, allowing craftsmen to incorporate various styles and profiles into their creations. This versatility adds an artistic touch to woodworking, showcasing the skill and precision of joinery craftsmanship.

How Is a Rabbet Joint Made?

The creation of a rabbet joint involves precise cutting and shaping of the wood pieces to form complementary grooves and edges, ensuring a seamless fit and strong connection between the jointed components.

This woodworking technique requires careful measurement and planning, often utilizing tools such as a table saw, chisels, and a marking gauge. To create dovetail rabbet joints, the woodworker needs to meticulously mark and cut the angled tails and pins, ensuring a symmetrical and snug fit. The process involves attention to detail and patience as the grooves and edges are carefully crafted to achieve a flawless joint, with the end result being a sturdy and visually appealing connection.

What Tools Are Needed to Make a Rabbet Joint?

Creating a rabbet joint demands the utilization of specific woodworking tools such as hand planes, routers, chisels, and precision saws, each contributing to the meticulous crafting and formation of the joint.

These tools play distinctive roles in the woodworking process, where hand planes are used to smooth and flatten the wood surfaces, routers are employed to create precise cuts along the edges, chisels aid in fine-tuning the joint's corners, and precision saws enable accurate shaping of the rabbet.

The mastery of these tools calls for a keen understanding of wood grain, appropriate cutting angles, and a steady hand to ensure the seamless blending of components in the creation of a perfectly crafted rabbet joint.

Chisel

The chisel is a crucial hand tool for refining and shaping the edges and grooves in the woodworking process, showcasing the precision and skills required for creating seamless rabbet joints.

It's essential to wield the chisel with a steady hand and keen eye, as even the slightest misalignment can compromise the joint's integrity. Woodworkers often use a marking gauge to accurately outline the dimensions of the rabbet joint before delicately paring away excess material with the chisel.

The subtle adjustments and careful removal of wood fibers with the chisel contribute to the snug fit of the joint, ensuring a sturdy and polished final product.

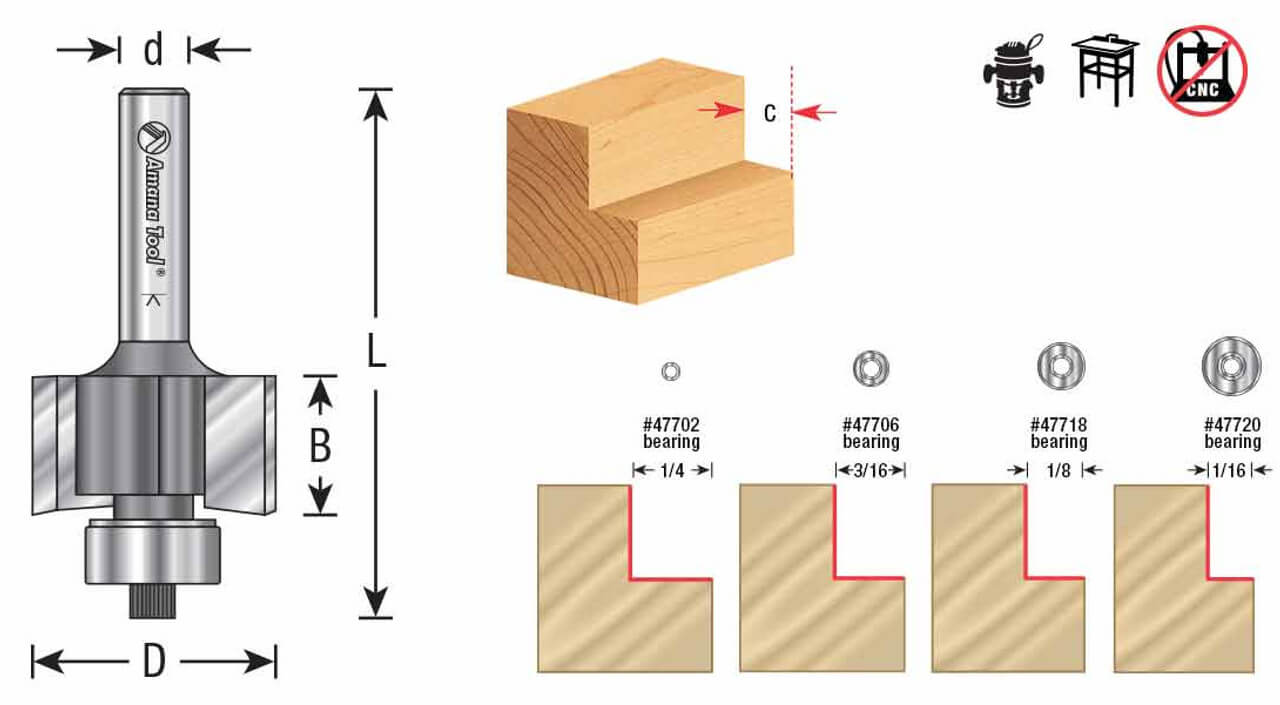

Router

The router plays a pivotal role in crafting rabbet joints by creating precise grooves and edges, showcasing advanced techniques and capabilities in woodworking construction.

It offers woodworkers the ability to achieve precise depths and widths, ensuring a snug fit for joining pieces together securely. With the aid of specialized rabbeting router bits and guides, the router allows for the creation of rabbet joints with utmost accuracy and consistency.

Its versatility enables craftsmen to work with various materials, making it an indispensable tool for creating strong and visually appealing joints in woodworking projects.

Table Saw

The table saw is a versatile woodworking tool essential for creating rabbet joints, contributing to the precise cutting and shaping required in various woodworking design and construction projects.

Its role in making rabbet joints allows woodworkers to join pieces of wood together seamlessly, ensuring sturdy and well-fitted constructions. The table saw's ability to cut precise and consistent rabbets enhances the overall quality and aesthetics of furniture, cabinetry, and other woodworking creations.

Its versatility enables craftsmen to experiment with different depths and widths of rabbet joints, opening up endless design possibilities. Whether constructing shelves, drawers, or frames, the table saw proves invaluable in achieving professional-grade rabbet joints with efficiency and accuracy.

Dado Blade

The dado blade offers specialized cutting capabilities that are instrumental in creating precise grooves and edges for crafting rabbet joints, showcasing the craftsmanship and handmade woodworking skills in the process.

It enables woodworkers to achieve clean and uniform cuts, enhancing the structural integrity and aesthetics of their projects. With its adjustable width and depth settings, the dado blade allows for customizing the rabbet joint dimensions to suit specific project requirements. This precision tool empowers artisans to create seamless interlocking joints, elevating the overall quality and durability of their woodworking creations. Mastering the dado blade technique is a testament to a woodworker’s dedication to honing their craftsmanship and delivering exceptional, bespoke pieces.

What Types of Rabbet Joints Are There?

Rabbet joints encompass various types, including:

- Edge rabbet

- End rabbet

- Lapped rabbet

- Mitered rabbet

- Rabbet and dado

each tailored for specific applications in furniture making and wood joinery.

Edge rabbet joints are commonly used for creating strong and seamless connections between two pieces of wood, while end rabbet joints provide stability in joining perpendicular pieces.

Lapped rabbet joints, known for their overlap, offer added strength, making them suitable for cabinet construction.

Mitered rabbet joints, with beveled edges, are favored for decorative corners, adding a touch of elegance to furniture.

Rabbet and dado joints, utilized for shelves and cabinets, ensure a snug fit and enhanced structural support.

Edge Rabbet

The edge rabbet joint is characterized by its precise edge-to-edge connection, showcasing the finesse and precision woodworking involved in creating seamless joints for woodworking projects.

This type of joint is commonly used in woodworking to join two pieces of wood at a right angle, allowing for the formation of clean, seamless edges. Its applications range from constructing cabinets and drawers to framing and paneling.

The joint requires meticulous measurements and cuts to ensure a perfect fit, emphasizing the importance of accuracy and attention to detail in woodworking. Woodworkers often use specialized tools such as rabbeting planes and router bits to create the precise cuts needed for this joint.

End Rabbet

The end rabbet joint offers versatility and woodworking skills in creating strong corner connections, showcasing its adaptability and contributions to varied woodworking techniques and designs.

This joint is commonly used in cabinet and furniture making, allowing pieces to fit together snugly and creating a clean and professional finish. Its application extends to creating picture frames, drawers, and bookshelves, demonstrating its wide-ranging benefits.

Woodworkers often employ precise measurement and cutting techniques to ensure the end rabbet joint aligns perfectly, enhancing the overall structural integrity of the final woodwork project. Its adaptability makes it an essential skill for artisans and carpenters working on diverse woodworking designs.

Lapped Rabbet

The lapped rabbet joint exhibits the hallmarks of quality woodworking and precise joinery, showcasing seamless overlapping connections that enhance the structural integrity and aesthetics of woodworking projects.

These joints are meticulously crafted to ensure a snug fit, adding strength and stability to the overall structure. Their clean lines and hidden fasteners create a visually appealing finish, elevating the craftsmanship of furniture, cabinets, and other woodworking pieces. Woodworkers rely on the precision of lapped rabbet joints to deliver both durability and beauty, making them an essential element in traditional and contemporary woodworking."

Mitered Rabbet

The mitered rabbet joint showcases intricate woodcraft and advanced router techniques, resulting in seamless corner connections and elegant woodworking designs that exhibit precision and artistry.

Crafting these joints involves precise measurement, careful trimming, and skillful router manipulation, culminating in a seamless fusion of wood pieces. Woodworkers utilize their adeptness in creating clean edges and angles, enhancing the overall aesthetic appeal of the finished piece.

The artistry lies in seamlessly blending the joints into the woodworking design, elevating the piece from mere functionality to a masterpiece of craftsmanship. This technique brings a sense of pride and satisfaction to woodworkers who seek to push the boundaries of traditional woodworking methods.

Rabbet and Dado

The rabbet and dado joint combination offers versatile applications in various woodworking projects, contributing to strong and seamless connections in construction and woodworking design.

These joints provide a secure and stable way to join wood pieces together, essential for creating durable furniture, cabinets, and shelving. Their integration ensures structural integrity and stability, allowing for clean and professional-looking finished products. They lend themselves well to creating intricate joinery, adding both aesthetic appeal and strength to woodworking projects.

While the rabbet joint forms a recess along the edge of a board, the dado joint creates a slot across the grain, providing a snug, interlocking fit for a wide range of woodworking applications.

What Are the Advantages of Using Rabbet Joints in Woodworking?

Utilizing rabbet joints in woodworking offers a multitude of advantages, including exceptional strength and durability, concealed joint aesthetics, and versatile applications across woodworking projects.

These joints provide a sturdy and reliable option, making them ideal for constructing furniture, cabinets, and frames. Their seamless integration into the wood's structure enhances the overall visual appeal of the finished piece. Rabbet joints allow for efficient use of materials and facilitate ease of assembly, reducing the need for additional fasteners or adhesives.

Whether used for creating intricate details or for joining large panels, these joints are favored by woodworkers for their ability to reinforce and beautify various woodworking projects.

Strong and Durable

Rabbet joints are renowned for their exceptional strength and durability, showcasing the precision woodworking and craftsmanship skills of woodworkers in creating robust and long-lasting connections.

These joints are formed by cutting a groove or channel into the end or edge of a woodworking piece and then fitting another piece into that groove. This unique construction method results in a seamless and secure connection, adding to the overall sturdiness and structural integrity of the furniture or woodworking project.

The precise fitting of the joint components reflects the meticulous attention to detail and expertise of the woodworker, ensuring that the finished piece not only looks beautiful but also withstands the test of time.

Concealed Joints

Rabbet joints offer the advantage of concealed connections, highlighting the art of joinery in creating seamless and aesthetically pleasing woodworking joints that enhance the overall craftsmanship and design.

These joints involve the careful creation of recessed channels or grooves along the edge or end of a piece of wood, allowing for another piece to fit snugly into the recess. This creates a strong and visually appealing joint that is commonly used in cabinet-making, bookshelves, and other furniture where seamless connections are crucial.

The precision and skill required in crafting rabbet joints contribute to the overall quality and durability of the finished woodworking project.

Easy to Make

Rabbet joints are relatively easy to make, showcasing the fundamental woodworking techniques and skills required to create sturdy and precise connections in woodwork projects.

These joints involve cutting a channel or recess along the edge or end of a piece of wood, allowing another piece to fit into the channel, creating a strong and seamless connection. The basic woodworking tools like a chisel, saw, and router are commonly used to create these joints, making them accessible to both beginners and seasoned woodworkers.

The precision and accuracy involved in cutting and aligning the rabbets contribute to the overall structural integrity of the final woodwork piece, be it a cabinet, drawer, or frame.

Versatile

Rabbet joints exhibit impressive versatility in their applications, contributing to diverse woodcraft and woodworking designs, showcasing adaptability and flexibility in various construction and design projects.

They are integral in creating seamless connections between wood pieces, providing structural support and enhancing the visual appeal of the final product. Whether used in cabinet-making, picture frames, or door and window construction, rabbet joints offer a reliable and aesthetically pleasing solution.

Their ability to accommodate various design needs, from simple to intricate, makes them a favorite among woodworkers and designers alike. The precision and strength of rabbet joints further enhance the overall quality and durability of woodworking projects.

What Are the Disadvantages of Using Rabbet Joints in Woodworking?

Despite their advantages, rabbet joints have certain disadvantages, including vulnerability to cross grain stress, the need for precision, and limited suitability in specific woodworking projects.

This vulnerability to cross grain stress can compromise the structural integrity of the joint, particularly when used in large or load-bearing projects. The precision required for creating rabbet joints can be demanding, leading to challenges for beginners or those without access to advanced woodworking tools.

Their limited suitability in specific projects, such as those requiring intricate joinery or where hidden joinery is preferred, may prompt woodworkers to explore alternative joint options.

Weak Against Cross Grain Stress

Rabbet joints are susceptible to weakness when subjected to cross grain stress, underscoring the importance of precision woodworking skills in crafting and reinforcing these joints for durability.

This vulnerability arises due to the perpendicular arrangement of the wood fibers, which can lead to splitting or cracking under strain. To mitigate this, precise cutting and fitting of the joint components become essential. Craftsmanship plays a pivotal role in ensuring that the rabbet joint is accurately formed, providing a snug fit that minimizes the potential for stress concentration. Without such precision, the joint may lack the necessary strength, highlighting the significance of meticulous attention to detail and skill in woodworking.

Requires Precision and Skill

Creating rabbet joints demands precision and skill from woodworkers, highlighting the mastery required in using tools such as chisels and routers to craft seamless and sturdy connections.

The meticulous process involves marking the joint accurately, as even a hair's breadth can impact the fit. Woodworkers meticulously carve out the recess with chisels, ensuring the depth and width align perfectly. Routers are utilized for larger-scale operations, their precision enhancing efficiency. Masters of this craft possess an acute understanding of wood grain and qualities, allowing them to select the right tools and techniques for each unique project, resulting in impeccably joined pieces with robust structural integrity.

Limited Use in Certain Projects

Rabbet joints may have limited applicability in certain woodworking projects, emphasizing the need for alternative joinery techniques and considerations in specific wood joinery and craftsmanship endeavors.

They are often used for simple cabinet construction or creating inset panels, but for more complex, load-bearing structures or projects requiring intricate craftsmanship, woodworkers might need to explore other versatile joinery options. Factors such as wood type, project functionality, and aesthetic preferences also play a crucial role in determining the most suitable joinery method.

In such cases, dovetail joints, mortise and tenon joints, or finger joints offer greater strength, durability, and visual appeal, meeting the diverse needs of woodworking projects.

Frequently Asked Questions

What are rabbet joints in woodworking?

Rabbet joints are a type of woodworking joint where one piece of wood has a groove or notch cut into it, and another piece of wood fits into that groove, creating a strong and secure connection.

What is the purpose of using rabbet joints?

Rabbet joints are commonly used in woodworking to join two pieces of wood at a right angle, such as in drawer construction or bookshelves. They provide a strong and stable connection and are also aesthetically pleasing.

What tools are needed to create a rabbet joint?

To create a rabbet joint, you will need a saw, chisel, and a router or dado blade. You may also need a mallet or hammer to help secure the pieces together.

What are the differences between a rabbet joint and a dado joint?

The main difference between a rabbet joint and a dado joint is the direction of the groove or notch. A rabbet joint has the groove cut along the edge of the wood, while a dado joint has the groove cut across the width of the wood.

Can rabbet joints be used for different types of woodworking projects?

Yes, rabbet joints can be used for a variety of woodworking projects, such as building cabinets, bookshelves, and frames. They are versatile and can be used for both functional and decorative purposes.

What are the benefits of using rabbet joints in woodworking?

Rabbet joints provide a strong and secure connection between pieces of wood, making them ideal for constructing furniture and other wooden objects. They also add a decorative element to the finished product.