Router Safety: Best Practices for Safe, Precise, & Efficient Routing

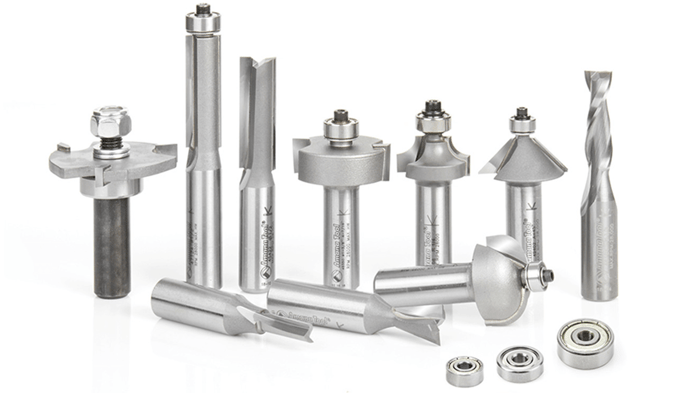

Working with a router unlocks a world of possibilities—router bits empower everything from joinery and edge profiling to shaping intricate curves. But like any power tool, routers demand respect, attention, and a strict adherence to safety practices. Understanding router safety is essential for anyone using these powerful machines, whether you're a seasoned pro or weekend woodworker.

Here’s a deeper look at the key guidelines, with added context to help you work smarter and safer:

1. Know Your Equipment

Always read your router and router bit owner’s manuals before use. Manufacturers provide essential safety and operational details specific to your tool. Skipping this step can lead to improper use and accidents.

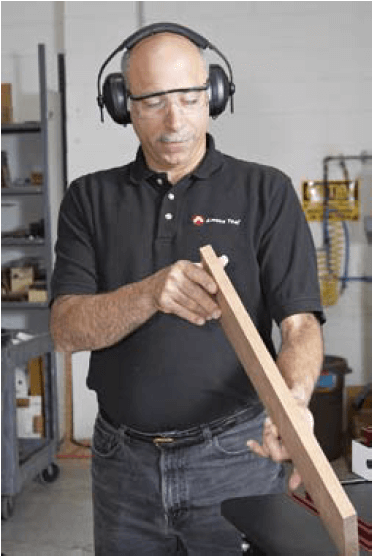

2. Wear Protective Gear

Eye and hearing protection are non-negotiable. Routers spin at incredibly high speeds and generate significant noise, as well as debris that can cause serious injury. Loose clothing or jewelry should be kept well away from the cutting area.

And print up some of our free downloadable safety posters, in English &/or Spanish, for the walls of your shop!

3. Observe RPM Limits

Never exceed the maximum recommended RPM for a router bit. Overspeeding a bit increases the risk of failure or shattering. Refer to Amana Tool's Max RPM chart online: View Max RPM Chart.

4. Use the Right Tool for the Job

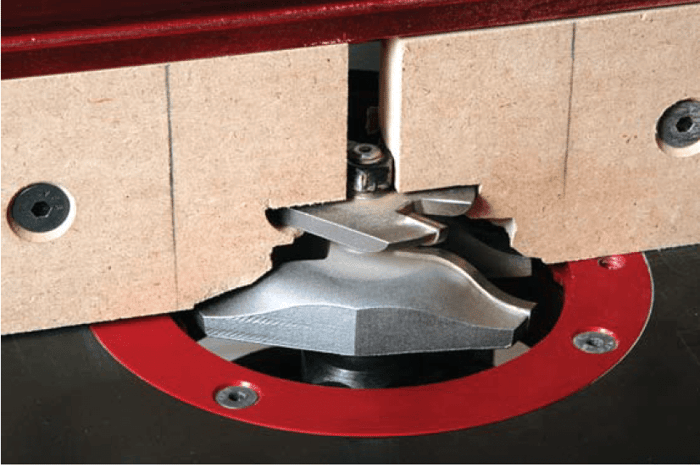

Large-diameter bits are powerful—but should only be used in a table-mounted router. Handheld routers are not stable enough for safe control of these bits. Amana Tool’s free catalog offers detailed application guidelines.

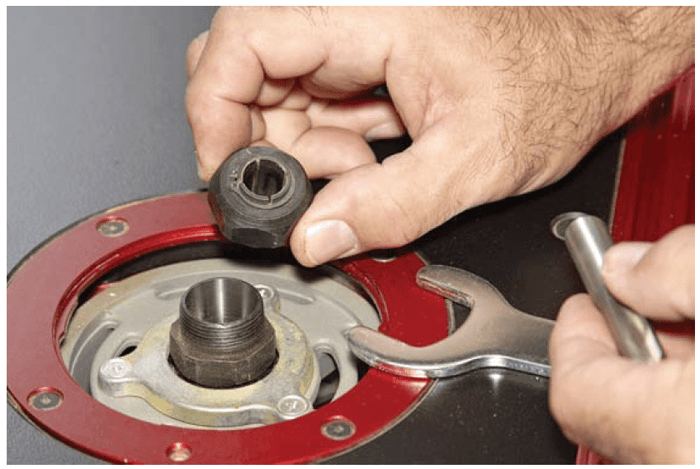

5. Inspect the Collet Regularly

The router collet holds the bit securely, and over time it can wear out or accumulate debris. Clean and inspect it often to maintain a solid grip on the bit and avoid slippage during operation.

6. Plan Your Cuts Carefully

Make sure your routing path never crosses the power cord—plan your passes with both safety and efficiency in mind.

Always keep your workspace organized to reduce hazards.

7. Power Off When Adjusting

Before plugging in your router or changing bits, ensure the power switch is OFF. This prevents accidental startups that could cause injury. (Better yet, when changing bits, just unplug the machine.)

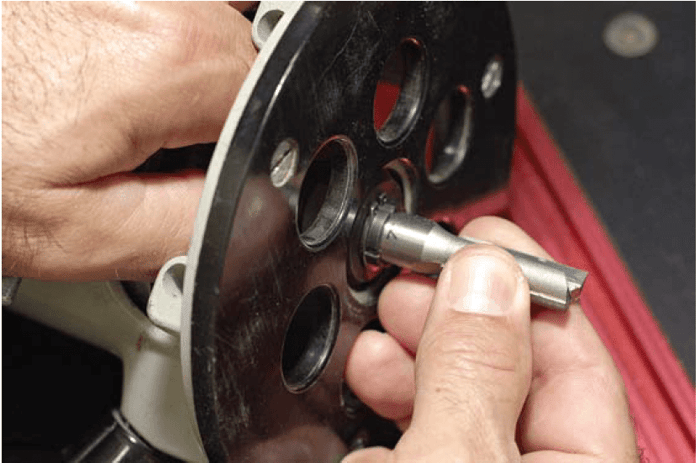

8. Proper Bit Installation

Never bottom out a bit in the collet. Insert it fully, then back it out about 1/8", or up to the stop line if marked. This prevents heat buildup at the bit base and allows for proper tightening.

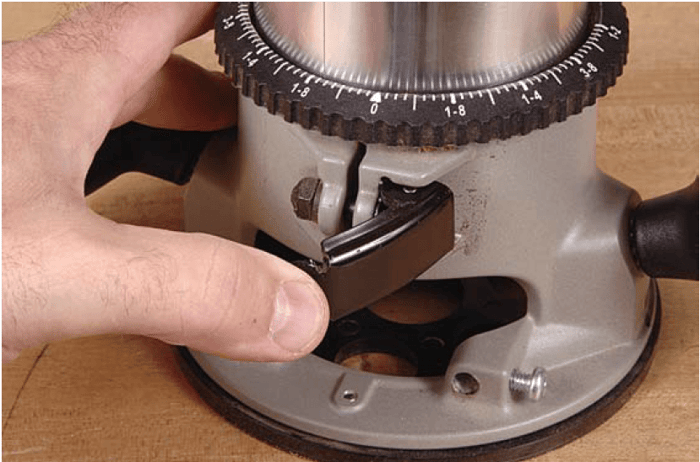

9. Secure the Router Motor

Before connecting to power, confirm the router motor is firmly locked into the base. A loose motor can shift during operation, compromising your cut and your safety.

10. Inspect Your Workpiece

Foreign materials like nails, staples, grit, or embedded screws can destroy your bit and pose a kickback risk. Always inspect and prepare your stock thoroughly.

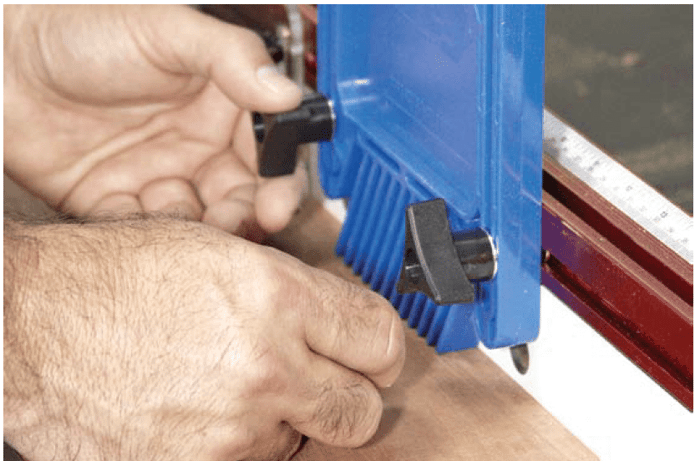

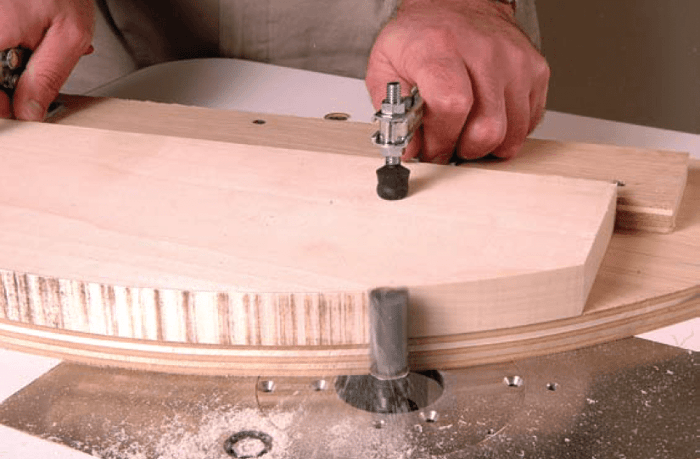

11. Use Featherboards for Stability

Featherboards help maintain steady, consistent pressure against the table and fence, minimizing movement and improving cut quality. They’re essential for safety and precision.

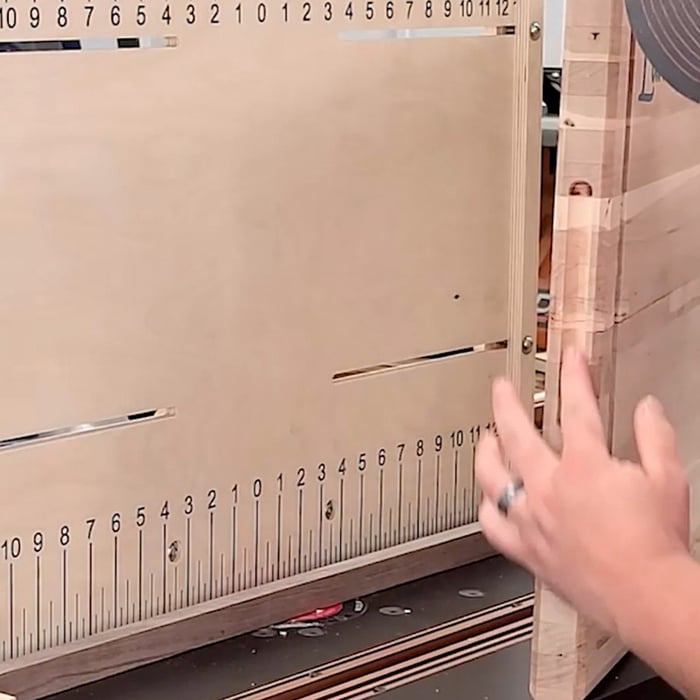

Cutting Board Finger Hold Jig CNC Plans, Downloadable and Customizable Adding finger grooves to the side of cutting boards can be very difficult to set up accurately and get good results. This jig solves that issue and makes easy work of it! Includes instructions on how to cut the jig on the CNC, how to set it up, and how to use it once complete.

Cutting Board Finger Hold Jig CNC Plans, Downloadable and Customizable Adding finger grooves to the side of cutting boards can be very difficult to set up accurately and get good results. This jig solves that issue and makes easy work of it! Includes instructions on how to cut the jig on the CNC, how to set it up, and how to use it once complete. 12. Use Jigs and Miter Gauges for Small Parts

Shaping the ends of narrow stock? Use a jig or miter gauge to keep your hands away from the bit and maintain control.

Narrow stock, indeed. Check out the video at the end of this post to watch how Matt does it.

Narrow stock, indeed. Check out the video at the end of this post to watch how Matt does it.

13. Fence Adjustments Matter

A tightly fitted fence helps support your workpiece and reduces tear-out. When using large diameter bits (e.g., raised panel bits), create a zero-clearance fence opening to prevent chip-out and support clean, precise cuts.

14. Routing Curves with Starting Pins

When shaping curved workpieces without a template, use a starting pin. It provides the initial support needed to ease the stock into the bit safely and smoothly.

15. Templates and Bearings: Plan Your Entry

When routing with a guide bearing and template, extend the template past the workpiece. This ensures the bearing contacts the guide first—not the bit—allowing for a safer, cleaner start to your cut.

Router safety isn’t just about avoiding injury—it’s about working efficiently, protecting your tools, and achieving better results. Whether you’re using an edge-forming bit or a massive raised panel cutter, these tips will help you stay in control, cut cleanly, and keep your shop safe.

Now, as promised, Matt's video: