Straight or Spiral Plunge Router Bits - Which is Better?

Straight plunge router bits and spiral plunge router bits are both used for making deep cuts or hollows in materials like wood, but they have distinct design characteristics and cutting behaviors.

So which is better? It depends. Spiral bits offer a smoother cut, better chip removal, and better finish, while straight bits are more cost-effective and better for rough, quick material removal.

You know what? I'm just going to come out and say it.

Unless you're working on a peripheral edge, where chip extraction is not an issue, a spiral bit is better.

Straight Plunge Router Bits

Design: These bits have straight flutes or cutting edges. They resemble a drill bit but are designed for lateral movement as well as plunging.

Cutting Action: Straight plunge bits cut in a chopping motion. This can lead to a rougher finish on the cut edges, especially in more splintery materials.

Material Removal: They are efficient at removing material quickly, but the removal is less smooth compared to spiral bits. The chips and debris are usually larger.

Applications: Straight plunge bits are often used for simple plunge cuts, grooving, and dadoes. They are effective in both hardwood and softwood.

Cost: Generally, straight plunge router bits are less expensive than their spiral counterparts.

Spiral Plunge Router Bits

Design: These bits have a spiral shape, similar to a twist drill bit. The spirals can be either up-cut, down-cut, or compression (a combination of both).

Cutting Action:

- Up-Cut Spiral Bits: These pull chips up and out of the cut. They're great for chip removal and preventing overheating but can lead to a rougher top edge.

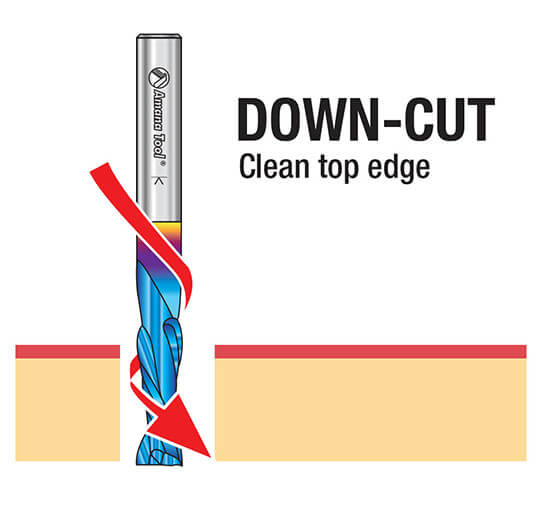

- Down-Cut Spiral Bits: These push chips downward, producing a cleaner top edge but potentially leading to more heat build-up.

- Compression Spiral Bits: These combine the features of both up-cut and down-cut, offering a clean cut on both the top and bottom edges, ideal for laminated materials.

Material Removal: Spiral bits cut more smoothly than straight bits, providing a finer finish. They are far better at chip evacuation. They're especially effective in preventing chipping and splintering in brittle materials like laminates and plywoods.

Applications: Spiral bits are versatile and can be used for a variety of tasks including plunge cuts, mortising, inlays, and working with delicate materials.

Cost: Spiral bits are generally more expensive due to their complex design and manufacturing process.

How to Choose: Straight or Spiral Plunge Router Bit?

Choosing between straight plunge router bits and spiral plunge router bits depends on the specific needs of your project, as each has its own advantages and ideal use cases. Neither is universally "better" than the other; rather, their effectiveness varies based on the application. Here's a comparison to help you decide which might be better for your situation:

Straight Plunge Router Bits

Advantages:

- Cost-Effective: Generally less expensive than spiral bits.

- Rapid Material Removal: Efficient at quickly removing large amounts of material.

- Versatility: Good for a variety of general woodworking tasks.

Best for:

- Projects where cost is a significant concern.

- Applications requiring rapid removal of material without needing a highly refined finish.

- General woodworking tasks where the precision and finish of a spiral bit are not necessary.

Spiral Plunge Router Bits

Advantages:

- Smoother Cut: Produces a finer finish with less splintering or chipping.

- Better for Delicate Materials: Ideal for laminates, plywoods, or materials prone to chipping.

- Variety in Cut Direction: Up-cut, down-cut, and compression options offer versatility for different applications (e.g., better chip removal, cleaner top or bottom edges).

Best for:

- Projects requiring a high-quality finish.

- Working with delicate or prone-to-chip materials like laminates and veneers.

- Situations where control of chip removal is important (e.g., up-cut for efficient chip evacuation or down-cut for a cleaner top surface).

Considerations for Choice:

Material Type: Spiral bits are often preferred for delicate materials, while straight bits can handle a broader range of woods effectively.

Desired Finish: If you need a smoother, cleaner finish, especially on the edges of the material, spiral bits are generally better.

Cost and Frequency of Use: If cost is a concern and the tool won't be used frequently, straight bits might be more economical.

Specific Application: Consider the exact nature of the task. For instance, for mortising or creating clean edges on laminated materials, spiral bits are preferable.

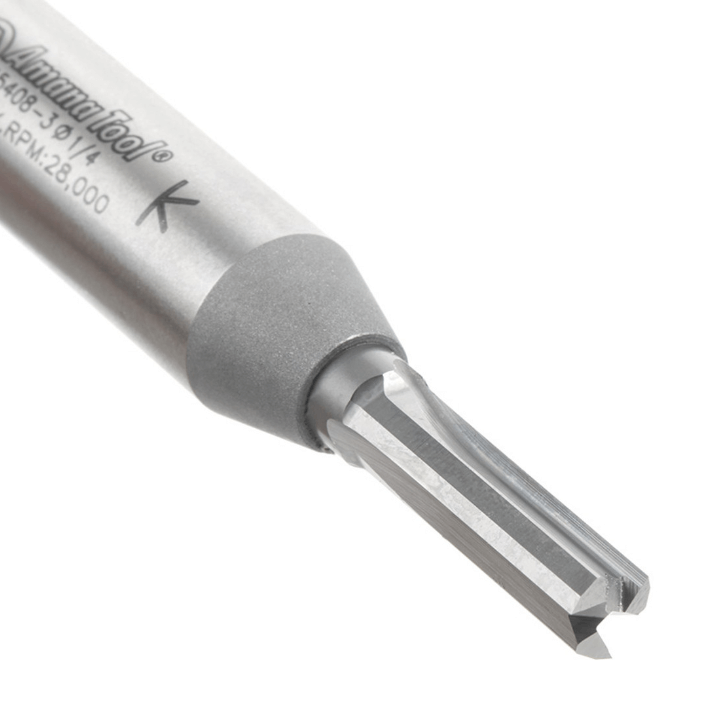

Both straight and spiral carbide router bits by Amana feature outstanding tool longevity, a tendency to stay sharper, mirror like carbide finish, excellent carbide brazing, a broad selection of sizes and most importantly quality of cut.

Both types of router cutters are available in a range of shank sizes ¼" through ¾". Choose your router bits carefully as different machines require different shank sizes. While you can use a collet adapter to fit a ¼" shank bit into a ¾" machine, it's not an ideal solution.

And, you definitely can't fit a ¾" shank into a ¼" machine.

Amana router bits cut a variety of materials from wood, plywood, MDF and other wood composites, plastics, and solid surface.

In the end, the "better" choice between straight and spiral plunge router bits depends on the specific requirements of your project. Evaluate based on the material you're working with, the type of cut you need to make, the importance of the finish, and your budget.