The Benefits of Using High-Speed Drill Bits in Your Projects

High-speed drill bits are essential tools for any DIY enthusiast or professional contractor looking to complete projects efficiently and effectively.

Discover the key differences between high-speed drill bits and regular drill bits, the numerous benefits of using HSS drill bits, the materials they can work on, and how to choose the right one for your project.

Get tips on using these drill bits safely, learn about common mistakes to avoid, and find out where you can purchase HSS drill bits to enhance your tool collection!

What Are High-Speed Drill Bits?

HSS drill bits are innovative tools engineered with advanced technology to enhance the performance and efficiency of drilling operations.

These drill bits are designed to deliver precision and speed, making them ideal for various applications in woodworking and metalworking. The specialized construction of high-speed drill bits allows them to resist heat buildup, ensuring a longer lifespan and consistent performance. With their sharp cutting edges and durable materials, these drill bits can cut through tough materials with ease, reducing the risk of overheating or wearing out quickly.

Whether you are working on a DIY project at home or tackling industrial-scale tasks, high-speed drill bits are indispensable tools that can make your drilling processes smoother and more effective.

How Are High-Speed Drill Bits Different from Regular Drill Bits?

High-speed drill bits stand out from regular drill bits due to their superior performance, durability, and quality craftsmanship, making them essential for professional and DIY projects.

These high-speed drill bits are designed to operate at much faster speeds, allowing for efficient drilling through various materials such as metal, wood, and plastic. Their advanced construction, often using cobalt or carbide materials, ensures they can withstand high temperatures and friction, resulting in increased durability and longevity. This enhanced durability not only improves the lifespan of the drill bit but also contributes to achieving more precise and accurate drilling results, making them a preferred choice for tasks that demand high precision and consistent performance.

What Are the Benefits of Using High-Speed Drill Bits?

Using HSS drill bits offers a multitude of benefits, including increased productivity, precise drilling capabilities, and achieving a smooth finish for optimal results.

These advantages make high-speed drill bits a valuable tool across various projects, whether you're working on woodworking, metalworking, or other DIY tasks. Their ability to penetrate materials quickly and efficiently not only saves time but also ensures accuracy in drilling holes of diverse sizes. This precision is particularly crucial for intricate work that demands flawless results. With high-speed drill bits, you can tackle projects with confidence, knowing that you can achieve professional-grade outcomes with ease.

Increased Speed and Efficiency

HSS drill bits excel in providing increased speed and efficiency, delivering time-saving benefits through efficient drilling processes for faster project completion.

- The sharp design and durable materials of high-speed drill bits allow for rapid penetration into various materials, reducing the time required to drill holes. By ensuring precision and accuracy during drilling, these drill bits minimize errors and rework, ultimately saving valuable time on projects.

- The superior heat resistance of high-speed drill bits enables continuous operation without the need for frequent breaks, further optimizing productivity and project timelines. With their ability to significantly cut down on drilling time, high-speed drill bits are indispensable tools for professionals looking to streamline their workflow and achieve faster results.

Versatility

HSS drill bits offer exceptional versatility, catering to a wide range of applications with their multipurpose design that provides tailored solutions for diverse tasks.

Whether you are a professional tradesperson, a DIY enthusiast, or a hobbyist, high-speed drill bits prove to be indispensable tools in your arsenal. From precise woodworking projects to heavy-duty metal fabrication, these drill bits showcase their ability to handle various materials with ease and efficiency. Their sharp cutting edges ensure clean and accurate holes, while their durable construction allows them to withstand the rigors of demanding work environments. With high-speed drill bits, you can tackle your projects with confidence, knowing that you have the right tool for the job.

Precision and Accuracy

Precision and accuracy are hallmarks of high-speed drill bits, ensuring precise holes and cuts for precision work that meets the highest standards of craftsmanship.

These specialized drill bits are designed to create clean and smooth holes with minimal effort, making them ideal for intricate designs and precision cutting tasks. Their high-speed capabilities allow them to efficiently bore through various materials such as wood, metal, and plastic with unparalleled accuracy.

Craftsmen and DIY enthusiasts alike rely on these drill bits to achieve flawless results in their projects, whether it involves intricate detailing or precise shaping. The sharp cutting edges of high-speed drill bits ensure a clean finish and the ability to work on delicate materials without causing any damage.

Durability and Longevity

High-speed drill bits are known for their exceptional durability and longevity, offering extended service life and enhanced durability for consistent performance over time.

They are constructed with high-quality materials that can withstand the demanding conditions of drilling through various tough materials. The durable construction of these drill bits ensures that they are able to maintain their sharpness and reliability even after prolonged use. This quality also translates to cost-effectiveness for users as they do not have to frequently replace worn-out bits. The long-lasting quality of high-speed drill bits is a testament to their ability to deliver reliable operation and consistent results, making them indispensable tools in any workshop or construction site.

What Materials Can High-Speed Drill Bits Work On?

High-speed drill bits are versatile tools capable of working on a wide range of materials, including metal fabrication and woodworking projects, ensuring efficient cutting and precise results.

Their ability to handle diverse materials such as metals and wood makes them essential for a range of applications. When used in metal fabrication, these drill bits exhibit excellent cutting efficiency, allowing for precise holes to be drilled in various metal surfaces. Similarly, in woodworking projects, high-speed drill bits deliver accurate and clean cuts, enabling craftsmen to create intricate designs and shapes with ease. The versatility and precision of these drill bits make them indispensable for both professional tradespeople and DIY enthusiasts alike.

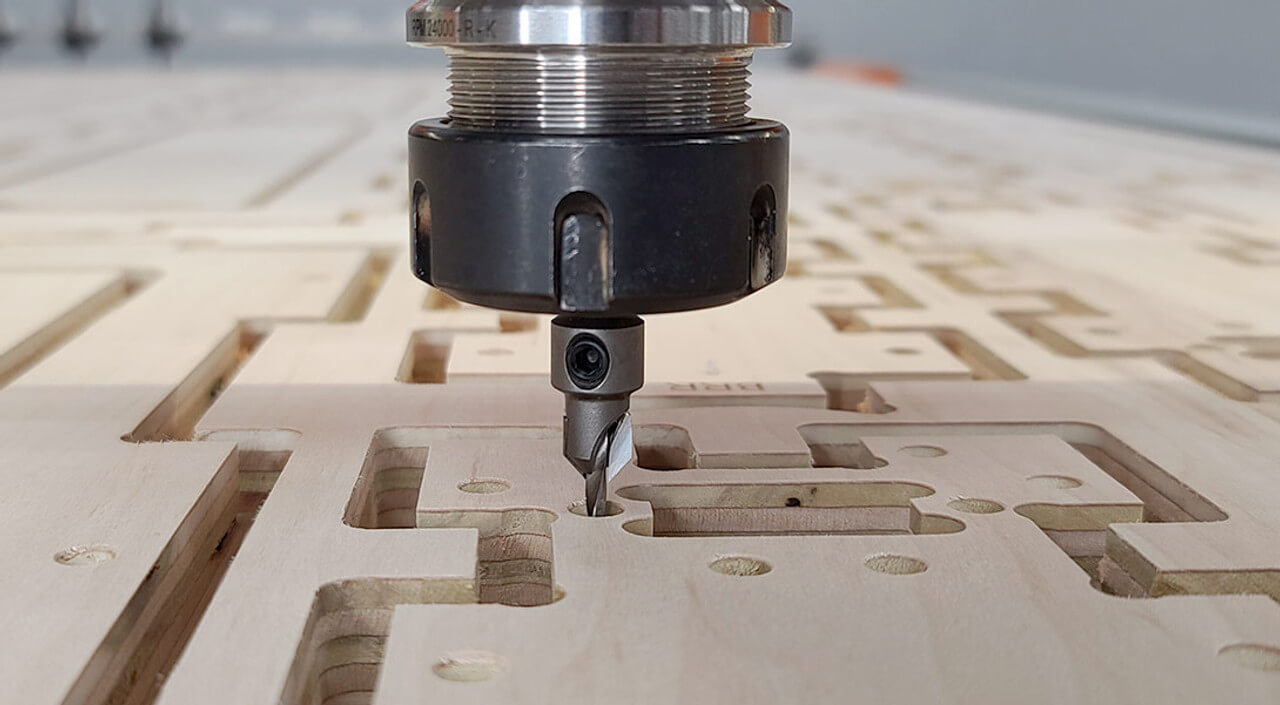

Can I Use HSS Drill Bits in My CNC Router?

Absolutely! Our HSS bits are meant to be used with Drill Adapters, Counterbores and Adjustable Depth Stop Countersinks.

In fact, drilling countersinks with these bits on the CNC machine is a great way to save time and have your pieces look great every time!

With the adjustable depth drill bit you can adjust them for whatever size material you’re working with. They are best used with a drilling toolpath, utilizing the peck drill option at 0.25” per pass with a 0.125” retract height.

For best results, run at 3,000 RPM with a 30 Inches Per Minute (IPM) plunge rate. No feed rate needs to be set with these as they only move up and down with the Z axis, not side to side. If your software doesn’t allow a 0 feed rate, you can enter 1 IPM in the feed rate as a placeholder.

How to Choose the Right High-Speed Drill Bit for Your Project?

Check the Flute Design

Evaluating the flute design of a HSS drill bit is crucial for ensuring smooth operation and a seamless drilling experience that enhances overall efficiency.

The different designs to cater to specific drilling needs, including the "HSS Twist" type, regular flute, and slow spiral designs. Each of these designs has characteristics that make them suitable for different applications:

HSS Twist Drill Bits:

- The twist drill bit is the most common type of drill bit for metalworking. The term "twist" refers to the spiral (helix) angle of the flutes, which are the grooves or channels wound around the body of the drill bit.

- Twist drill bits are designed to provide a good balance between durability and cutting speed, making them suitable for a wide range of materials and applications.

- The helix angle of a standard twist drill bit is usually around 30 to 40 degrees, which is considered a "normal" or "regular" helix angle.

Regular Flute Drill Bits:

- Regular flute drill bits can also be twist drill bits, but the term "regular flute" emphasizes the design of the flutes rather than the spiral angle.

- These drill bits are designed for general-purpose drilling in most materials, including metal, wood, and plastic.

- The flutes are designed to efficiently remove chips and debris from the hole, keeping the drill bit cool and reducing wear.

Slow Spiral (Low Helix) Drill Bits:

- Slow spiral drill bits have a smaller helix angle, typically less than 30 degrees. This design is also referred to as a "low helix" drill bit.

- The slow or low helix angle makes these bits more efficient at cutting hard, abrasive materials such as stainless steel or titanium. The slower spiral helps to reduce the buildup of heat and improves chip removal, which is critical in hard materials.

- They are particularly useful for applications requiring a high degree of control and precision, as the slower spiral rate reduces the tendency of the bit to "walk" or wander at the start of drilling.

The main difference between these types of HSS drill bits lies in their flute design and helix angle, which affects their cutting performance, chip removal, heat generation, and suitability for different materials. "HSS Twist" generally refers to the common, versatile design, "regular flute" emphasizes the chip removal capability, and "slow spiral" or "low helix" bits are tailored for hard materials where control and reduced heat are paramount.

Consider the Shank Size

Considering the shank type of a HSS drill bit is important to ensure compatibility and enhanced control during drilling operations for superior results.

If you are using an HSS bit in a CNC router, then, for 5/16" dia. round shank use a 7-8mm Spring Collet. (A spring collet is a holding device designed to reduce the vibrations on the tools and motors, assure better results and prolong the life of the tools and electrospindles.) For 3/8" dia. round shank use 9-10mm Spring Collet.

What Are Some Tips for Using High-Speed Drill Bits Safely?

Utilizing HSS drill bits safely involves following essential tips such as leveraging safety features and ensuring user-friendly practices to maintain a secure and effective drilling environment.

-

It is crucial to carefully read and understand the user manual accompanying the drill bits to familiarize oneself with the specific features and operational instructions.

-

Before starting any drilling work, always wear appropriate safety gear such as goggles to protect your eyes and gloves to shield your hands.

-

It's vital to inspect the drill bits regularly for any wear or damage and replace them as needed to prevent accidents or damage to the workpiece.

By incorporating these safety measures into your drilling routine, you can ensure a safe and successful drilling experience.

What Are Some Common Mistakes to Avoid When Using High-Speed Drill Bits?

Avoiding common mistakes when using these drill bits is crucial for maintaining improved accuracy, enhanced control, and overall safety during drilling operations.

- One common mistake to avoid is applying too much pressure when drilling. Many individuals tend to push too hard, which can lead to overheating the drill bit, causing it to dull quickly and result in imprecise drilling.

- Failing to secure your workpiece properly can lead to dangerous kickbacks or the workpiece spinning out of control. Another important consideration is using the correct speed setting for the material being drilled to prevent overheating and potential damage.

Always wear proper safety gear, such as goggles and gloves, to protect yourself from flying debris and potential injuries.

Frequently Asked Questions

What are the benefits of using HSS drill bits in your projects?

HSS drill bits offer several advantages, including faster drilling speeds, increased precision, and better durability.

How do HSS drill bits help with faster drilling speeds?

These drill bits are specifically designed to rotate at faster speeds, allowing for quicker drilling times and increased productivity.

Can HSS drill bits improve the precision of my projects?

Yes, HSS drill bits have sharper cutting edges and are made with high-quality materials, resulting in more accurate and precise holes.

Are HSS drill bits more durable than standard drill bits?

Absolutely. HSS drill bits are made from strong materials such as cobalt or titanium, making them more resistant to wear and tear and able to withstand high drilling speeds.

What types of materials can be drilled using HSS drill bits?

HSS drill bits can be used on a variety of materials, including wood, metal, plastic, and even concrete, making them a versatile tool for any project.

Are there any safety precautions to consider when using HSS drill bits?

As with any power tool, it is important to wear proper safety gear, such as eye protection, and to carefully follow the manufacturer's instructions for use to avoid accidents or injuries.