Jointers & Planers: Top Tips to Avoid Snipe in Wood Planing

What is Snipe in Wood Planing?

Snipe refers to surface imperfections that appear at the beginning or end of a board during the planing process. These dips or grooves can ruin the overall finish of your workpiece. Understanding the causes of snipe and how to prevent it is essential for achieving smooth, even surfaces in woodworking projects.

How Snipe Occurs in Planers and Jointers

Snipe typically happens when uneven pressure is applied by the machine's rollers. In the case of a planer, this happens when the board is fed through unevenly, often due to improper setup. For jointers, snipe occurs when the board isn't fully supported, especially at the entry or exit point. Both tools, if not set up properly, can create this unwanted effect.

Jet 708475 JJP-12 12 Inch Jointer / Planer Combo 3HP 1PH 230V Extremely quick changeover between jointing and planing functions. Fence does not need to be removed.

Jet 708475 JJP-12 12 Inch Jointer / Planer Combo 3HP 1PH 230V Extremely quick changeover between jointing and planing functions. Fence does not need to be removed. Common Causes of Snipe in Jointers & Planers

Several factors contribute to snipe in both jointers and planers:

- Improper machine setup: Misaligned rollers or dull blades in either the jointer or planer can result in uneven cuts.

- Wood misalignment: If the board is not properly positioned or supported, it may feed unevenly through either machine.

- Inconsistent feed rate: A variable feed rate can cause one side of the board to be planed more aggressively than the other, leading to snipe.

- Wood defects: Wood with complex grain patterns, such as curly or figured wood, is more likely to develop snipe when fed through the machines.

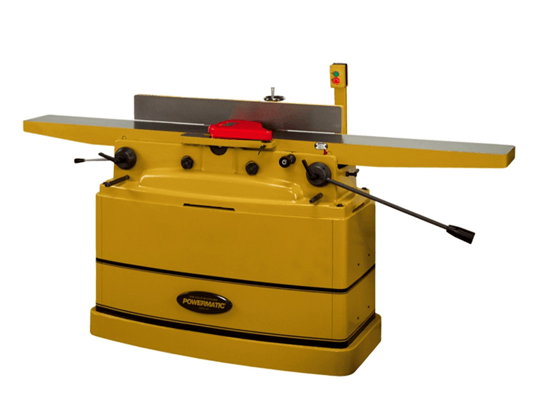

Powermatic 1610082 PJ-882HH, 8 Inch Parallelogram Jointer, 2HP 1PH 230VHelical Cutterhead Helical cutterhead with knife inserts provides smoother, quieter cutting and finer finish than conventional systems.

Powermatic 1610082 PJ-882HH, 8 Inch Parallelogram Jointer, 2HP 1PH 230VHelical Cutterhead Helical cutterhead with knife inserts provides smoother, quieter cutting and finer finish than conventional systems.

How to Prevent Snipe in Jointers and Planers

To minimize the risk of snipe, it’s important to focus on proper setup and consistent feeding, whether you're using a planer or a jointer.

Best Practices for Planers

- Calibrate your planer: Ensure that the infeed and outfeed rollers are aligned properly and that the blades are sharp. Regularly check the planer for wear and tear.

- Feed the wood properly: Maintain a consistent feed rate, ensuring the board is supported evenly at both ends.

- Use support tables: Infeed and outfeed tables will help stabilize the board as it enters and exits the planer, reducing snipe.

- Plane with the grain: Planing in the direction of the grain minimizes the chances of tear-out and helps prevent snipe.

Best Practices for Jointers

- Ensure flatness: Make sure the board is fully flat on the jointer's bed before feeding it in. A warped board can cause uneven cuts and snipe.

- Use adequate support: Support the board as it enters and exits the jointer, preventing it from dipping at the edges.

- Adjust the cut depth: Set the depth of the cut on the jointer to a shallow setting to avoid removing too much material at once, which can cause snipe.

- Make multiple passes: When working with a thick board, make multiple shallow passes rather than trying to remove a large amount of material at once.

How to Fix Snipe in Wood Planing

If snipe occurs despite your best efforts, there are ways to fix it:

- Sanding: Use sandpaper with progressively finer grits to smooth out the affected area.

- Hand planing: A hand plane can be used to remove deeper snipe marks before sanding.

- Edge refining: For minor snipe, using a block plane or scraper can help smooth the edges and create a uniform finish.

Jet 722130 JWP-13BT 13 Inch Planer with Helical Style Head The New JET 13" Planer produces a smooth and consistent cut surface thanks to its helical-style cutterhead with 6 rows of 26 individual quick change inserts which can be easily rotated or replaced if damaged or worn.

Jet 722130 JWP-13BT 13 Inch Planer with Helical Style Head The New JET 13" Planer produces a smooth and consistent cut surface thanks to its helical-style cutterhead with 6 rows of 26 individual quick change inserts which can be easily rotated or replaced if damaged or worn.

Alternatives to Wood Planing

If you're looking for alternative methods to achieve smooth surfaces without relying solely on a planer, consider these options:

- Smoothing planes: A smoothing plane can provide a flat surface with less risk of snipe.

- Edge jointing: Using a jointer to smooth and flatten edges before planing can help reduce the risk of snipe.

Frequently Asked Questions

What is snipe and how does it occur?

Snipe is a dip or indentation at the ends of a board when planing. It occurs due to uneven pressure from the machine's rollers, which can happen in both planers and jointers.

Why does snipe happen in planers and jointers?

Snipe occurs when pressure is uneven on the wood, often due to misalignment, incorrect feed rates, or dull blades. It can happen in both planers and jointers when the workpiece is not supported or fed properly.

How can I prevent snipe in a planer or jointer?

Ensure the board is well-supported throughout the process. Use support tables, feed the board evenly, and keep the machine calibrated with sharp blades. A sacrificial board at the beginning and end can also help prevent snipe.

Can snipe be fixed once it occurs?

Yes, snipe can be fixed by sanding, hand planing, or refining the edges with hand tools. It's best to prevent it from happening, but it can be repaired.

Does the type of wood affect the likelihood of snipe in planers and jointers?

Yes, certain woods, particularly those with complex grain patterns like curly or figured wood, are more prone to snipe. These woods require extra care when planing or jointing.