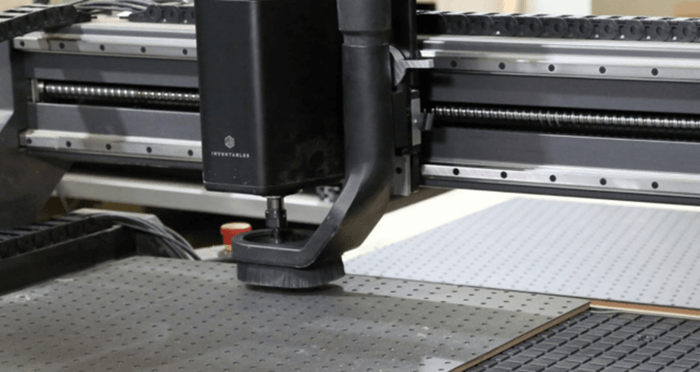

Troubleshooting Common CNC Machine Problems

Even the best CNC machines run into problems. Whether you're running a small shop or operating industrial equipment, issues like inaccurate cuts, spindle malfunctions, or tool chatter can grind production to a halt. The good news? Many of these problems have recognizable causes—and practical fixes.

Understanding CNC Machine Basics

How CNC Machines Work

Computer Numerical Control (CNC) machines use a combination of motors, sensors, and programmed instructions (usually G-code) to move tools with high precision. The controller interprets the code and drives the motion system—typically via ball screws or linear guides—across multiple axes.

Key Components

- Spindle: Drives the cutting tool and determines RPM.

- Automatic Tool Changer (ATC): Switches tools automatically for complex jobs.

- Axis Motors and Drives: Provide motion to X, Y, and Z axes.

- Controllers and Sensors: Coordinate movement and monitor position.

Common CNC Problems and How to Troubleshoot Them

1. Inaccurate Cuts and Measurements

- Symptoms: Parts out of spec, irregular dimensions, misalignment.

- Causes: Mechanical backlash, loose ball screws, sensor errors, uncalibrated home position.

- Fixes:

- Tighten or replace worn ball screws.

- Check for mechanical play in guides or couplers.

- Calibrate absolute position sensors and re-home axes.

- Inspect fixturing for movement or misalignment.

2. Tool Chatter and Poor Surface Finish

- Symptoms: Visible vibration marks, rough surfaces, audible chatter.

- Causes: Incorrect feeds and speeds, dull tools, unstable workholding, spindle wear.

- Fixes:

- Reduce tool overhang and improve fixturing.

- Use recommended speeds and feeds for your material.

- Try climbing vs. conventional cutting strategies.

- Replace worn tools and check spindle runout.

3. Spindle or Axis Motor Issues

- Symptoms: Spindle won't turn, sudden stops, unusual noise or heat.

- Causes: Faulty power supply, overheating, loose belts, motor or VFD failure.

- Fixes:

- Check power-draw sensors and inspect electrical connections.

- Look for tripped breakers or blown fuses.

- Inspect motor belts and cooling fans for dust buildup.

- Test voltage output from the VFD and listen for bearing noise.

4. Frequent Tool Breakage or Wear

- Symptoms: Tools breaking mid-job, excessive wear or chipping.

- Causes: Improper feeds and speeds, wrong tool for the material, worn ATC mechanisms.

- Fixes:

- Verify tooling recommendations for material type and depth of cut.

- Use tool wear monitoring or load-based alarms when possible.

- Inspect ATC for misalignment or improper clamping force.

5. Unexpected Crashes and Axis Drift

- Symptoms: Tools crashing into fixtures, machine halting mid-cycle, inaccurate returns to zero.

- Causes: Software bugs, bad post-processor code, controller memory errors, unintentional offsets.

- Fixes:

- Run toolpath simulations with collision detection software.

- Double-check post-processor settings and machine compatibility.

- Clear offsets and reinitialize machine coordinates.

- Update controller firmware if errors persist.

Preventing CNC Issues Before They Happen

Regular Maintenance and Lubrication

Clean chips and dust daily, check lubrication lines, and inspect linear bearings regularly. Backlash and overheating often stem from neglected maintenance.

Monitoring Tool and Spindle Load

Use spindle load graphs or power-draw sensors to catch overloads before they damage tools. This also helps identify hidden material inconsistencies.

Using High-Quality Materials and Coolants

Poor-quality stock can damage tools and introduce vibration. Always verify material specs and coolant concentrations.

Training Operators on Safety and Programming

Most crashes come from operator error or rushed setups. Proper training in CAD/CAM, G-code, and machine operation saves time, tools, and money.

When to Call in a Professional

Electrical and Sensor Failures

Encoder problems, shorted wires, or controller issues can be dangerous if handled improperly. A licensed technician should handle diagnostics here.

Major Alignment or Mechanical Rebuilds

Bed leveling, ball screw replacement, and servo tuning are best left to experienced CNC service pros.

Advanced Diagnostics with Software Tools

If you're running into recurring crashes or inconsistent tolerances, a technician with access to OEM diagnostic software can spot faults not visible through manual inspection.

Bottom line: Most CNC issues stem from a few common causes—mechanical wear, programming errors, or neglected maintenance. Know the warning signs, act early, and don’t be afraid to bring in expert help when needed. A well-tuned machine is a productive machine.

Check out Matt's downloadable & customizable Work Holding Wasteboard CNC Plans

Router Bits

Router Bits Spektra Router Bits

Spektra Router Bits Saw Blades

Saw Blades Shaper Cutters

Shaper Cutters Boring & Drilling

Boring & Drilling

CNC Router Bits

CNC Router Bits CNC Router Bit Sets

CNC Router Bit Sets CNC Machines

CNC Machines CNC Machine Accessories

CNC Machine Accessories Free Vectric® & Fusion 360™ CNC Files

Free Vectric® & Fusion 360™ CNC Files CNC Software

CNC Software CNC Plans Downloads

CNC Plans Downloads CNC Vacuum Table Vacs

CNC Vacuum Table Vacs  Laser Cutters Accessories

Laser Cutters Accessories Laser Cutters

Laser Cutters CNC Sanding Tools

CNC Sanding Tools

CNC Machines

CNC Machines Drilling & Screwdriving

Drilling & Screwdriving Filtration, Dust Extractors & Collectors

Filtration, Dust Extractors & Collectors Edge Banders

Edge Banders Joinery Machines

Joinery Machines Jointers & Planers

Jointers & Planers Material Handling

Material Handling Metalworking Tools

Metalworking Tools  Mobile Tool Bases & Universal Stands

Mobile Tool Bases & Universal Stands Oscillating Multi-Tools

Oscillating Multi-Tools Power Tool Accessories

Power Tool Accessories Routers & Shapers

Routers & Shapers Sanders & Polishers

Sanders & Polishers Saws

Saws Wood Turning Machines and Accessories

Wood Turning Machines and Accessories

Amana Tool

Amana Tool

Sawstop

Sawstop

Festool

Festool

Woodpeckers

Woodpeckers

Timberline

Timberline

Stepcraft

Stepcraft

A.G.E. Series

A.G.E. Series

Fein

Fein

Jet

Jet

VECTRIC

VECTRIC

Powermatic

Powermatic

Laguna Tools

Laguna Tools Carbide 3d

Carbide 3d

Onefinity CNC

Onefinity CNC

Shaper

Shaper

xTool

xTool

AirWeights

AirWeights

Panto Router

Panto Router

Black Box Vac

Black Box Vac

SST

SST

Jessem

Jessem

Donek Tools

Donek Tools