Vacuum Table: Maximize CNC Accuracy with Workholding Systems

What is a Vacuum Table Workholding System?

A vacuum workholding system uses negative pressure to secure materials in place during CNC machining processes, such as routing and milling. It replaces traditional clamps and fixtures, offering precise control for various materials like aluminum, plastic, and composite. This system ensures high precision and stability during machining operations.

Benefits of a Vacuum Table System

These systems offer multiple advantages, including improved setup time, increased efficiency, and reduced material damage. By securing workpieces with suction, it eliminates the need for mechanical clamping, making the process faster and cleaner. This results in cost savings and more consistent results.

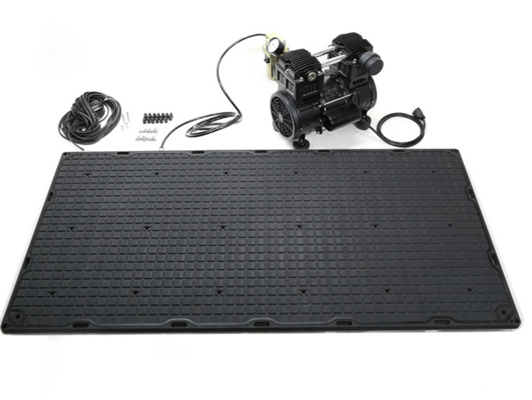

AirWeights Complete System 24 x 48 Vacuum Table Workholding System The vacuum table is a powerful tool on a CNC machine, offering dozens of advantages that benefit users of all levels.

AirWeights Complete System 24 x 48 Vacuum Table Workholding System The vacuum table is a powerful tool on a CNC machine, offering dozens of advantages that benefit users of all levels.Increased Efficiency and Accuracy

One of the key benefits of a vacuum workholding system is the increase in accuracy and efficiency. The stable grip provided by the vacuum minimizes part movement during machining, improving dimensional precision. This makes it an essential tool in environments where high precision is critical, such as in aerospace or automotive industries.

Cost Savings

Vacuum systems can lead to cost reductions in manufacturing. They reduce the need for manual setup, cut down on tool changes, and lower the risk of material damage. This enhances operational productivity and offers long-term financial benefits, making them a smart investment for small manufacturers and high-precision workshops.

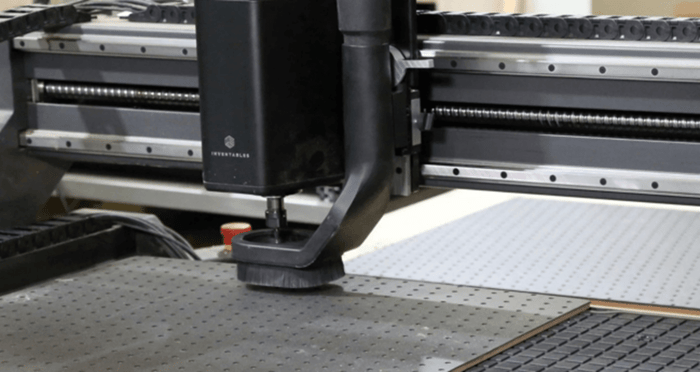

How the System Works

The vacuum system works by creating a strong suction force that holds workpieces firmly in place. This is achieved through a vacuum pump connected to the table surface, which has a series of small holes. When the vacuum is activated, air is removed, creating a secure hold on the material, without the need for clamps.

AirWeights Complete System 24 x 48 Vacuum Table Workholding System Vacuum workholding removes the need for clamps, screws, tapes, or glues. You can secure your work to the table faster than ever, and there will be no obstacles in the way for your machine to run into.

AirWeights Complete System 24 x 48 Vacuum Table Workholding System Vacuum workholding removes the need for clamps, screws, tapes, or glues. You can secure your work to the table faster than ever, and there will be no obstacles in the way for your machine to run into.Choosing the Right Workholding System

When selecting a vacuum workholding system, consider factors such as table size, material compatibility, and the type of machining you are performing. Different materials may require varying levels of suction power, and the system should be adaptable to your existing equipment.

Installation and Maintenance

Proper installation and regular maintenance are crucial for optimal performance. To ensure efficiency, clean the table surface regularly and inspect the vacuum pump for leaks or wear. Proper maintenance extends the system’s life and maintains its suction power, preventing costly downtime.

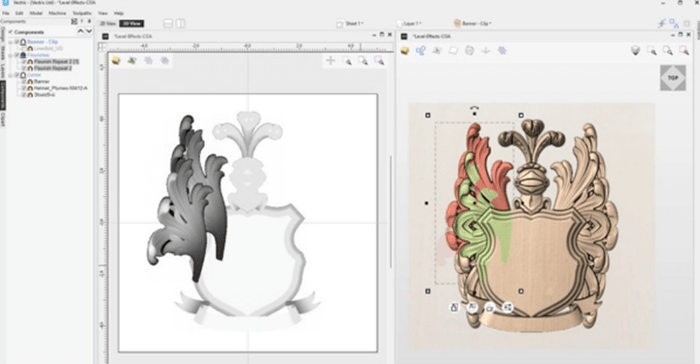

Common Applications of Vacuum Workholding

Vacuum workholding is widely used in CNC machining, woodworking, and aerospace applications. In woodworking, it helps achieve fine, intricate cuts. In CNC machining, it ensures secure, stable holds on complex parts, increasing precision and reducing setup time.

AirWeights Complete System 24 x 24 Vacuum Table Workholding System With a total of 10 suction ports, and a fully reconfigurable gasket grid, you can hold a variety of shapes, sizes, and quantities of work-material; making the system incredibly convenient and versatile.

AirWeights Complete System 24 x 24 Vacuum Table Workholding System With a total of 10 suction ports, and a fully reconfigurable gasket grid, you can hold a variety of shapes, sizes, and quantities of work-material; making the system incredibly convenient and versatile.Frequently Asked Questions

What is a vacuum table workholding system?

A vacuum table system uses suction to securely hold workpieces during CNC machining, ensuring accuracy and efficiency without traditional clamps.

How does it work?

The system creates suction through small holes in the table surface, holding the workpiece securely in place. This ensures stability during machining and allows for precise cuts.

What are the benefits?

The main benefits include faster setup times, reduced material damage, and increased production efficiency. Vacuum workholding systems eliminate the need for clamps and fixtures, reducing downtime and improving accuracy.

Can it be used for all materials?

While vacuum workholding is versatile, it is most effective on lightweight and flat materials. Heavier materials may require additional support or alternative clamping methods.

Is maintenance difficult?

No, maintenance is relatively easy. Regular cleaning of the table surface and inspection of the vacuum system components ensure continued performance and prevent issues.