PRODUCT DETAILS

Click an item to expand and learn more

-

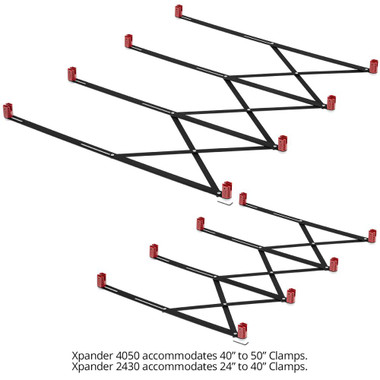

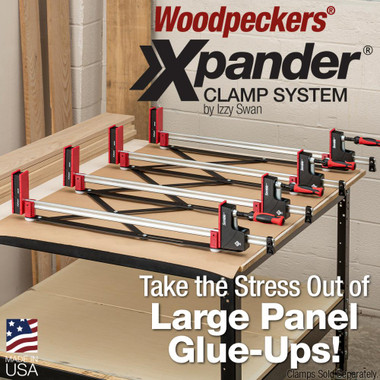

Gluing up table tops and large panels often turns into a wrestling match between you and a bunch of clamps you’re trying to keep upright and evenly spaced. Creative genius, Izzy Swan, invented a clamp carrier that dramatically speeds up the process and eliminates the stress. Woodpeckers has worked closely with Izzy in creating our new Xpander Clamp Systems. The Xpander works with most any brand of parallel jaw clamp and keeps 4 clamps perfectly spaced, from butted up right next to each other up to 15" apart on the smaller model and 17-1/2" apart on the larger. Adjusting the spacing is as simple as sliding the two outside clamps in or out…the linkage system automatically keeps the middle clamps straight, upright and evenly spaced. When the job is done, just slide the clamps together and store them away as a single unit.

Both models give you the full range of your clamps. The clamping head can easily move from inside the bar holder to outside the bar holder, and the bar holder itself adjusts 5". This means there are no “dead spots”. You can squeeze every inch out of your clamps’ capacity.

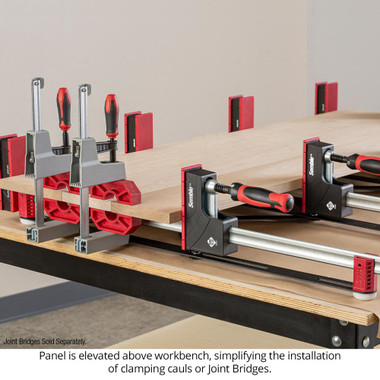

Working with your clamps held in an Xpander system makes everything about your glue-up go smoother. The clamps are locked vertically, so they won’t fall over if you bump them. The clamping heads adjust easily along the rail, since the bar is held in place. As mentioned before, spacing between the clamps is automatic. And, the clamps are elevated off the work surface, simplifying the application of clamping cauls or Woodpeckers Joint Bridges.

The linkage bars of the Xpander are powder-coated steel…glue pops off easily. The clamp holders are tough injection-molded polycarbonate. Each clamp holder ends in a nylon foot that slides easily and won’t mar the surface of your workbench. Set screws in the clamp holders quickly and easily secure your clamps in the Xpander. Once installed, you can leave them in all the time, or pop them out if needed individually.

When the glue is dry and the panel has moved to the next step, just collapse the Xpander and stand it against a wall or slide it on a shelf…the entire assembly is barely larger than the clamps themselves and it stores neatly without turning into a tangled mess like loose clamps tend to do.

The larger 4050 Xpander accommodates 40" to 50" clamps. The smaller 2430 Xpander handles 24" to 40" clamps. The 4050 expands to 53" from edge to edge, allowing you to glue up panels up to 60" long. The 2430 expands to 46" edge to edge, letting you glue up panels 53" long.

Like all Woodpeckers products, Xpander Clamp Systems are precisely built and carefully inspected in our Strongsville, Ohio facility, just south of Cleveland.

Additional Info

- **Crafting Table Tops**: Ideal for woodworkers creating large, flat surfaces such as dining tables, workbenches, or desks, ensuring even pressure and alignment during the glue-up process.

- **Assembling Large Panels**: Perfect for constructing panels for cabinetry, large artwork frames, or any project requiring wide, flat surfaces.

- **Gluing Long Boards**: Useful for edge-gluing long boards to make wider panels, such as for countertops or shelving, without worrying about clamp stability.

- **Workshop Organization**: Keeps clamps neatly organized and easily accessible, reducing clutter and making the most of workshop space.

- **Simplifying Complex Glue-Ups**: The automatic spacing and vertical lock-in make it easier to manage complicated glue-ups with multiple pieces, ensuring a smooth, even join.

- **Enhancing DIY Projects**: Amateur and professional DIY enthusiasts can achieve professional-level precision in their projects, making it easier to tackle ambitious builds.

- **Furniture Making**: Essential for furniture makers looking for an efficient and reliable way to assemble pieces of their creations, from chairs to bookcases.

- **Woodworking Classes**: An excellent tool for educational settings, allowing students to learn about proper clamping techniques and the importance of even pressure during glue-ups.

- **Restoration and Repair Work**: Ideal for restoring or repairing wooden furniture and panels, providing the necessary support and pressure for effective bonding.

- **Crafting Custom Wooden Doors and Panels**: Enables the creation of custom-sized wooden doors and large decorative panels with ease and precision.

-

-

Download Manual Instructions

Download Manual Instructions Xpander Clamp System | Woodpeckers Woodworking Tools

Xpander Clamp System | Woodpeckers Woodworking Tools Cool Features Of The NEW Xpander Clamp System | Deep Dive | Woodpeckers Tools

Cool Features Of The NEW Xpander Clamp System | Deep Dive | Woodpeckers Tools Making The Xpander Clamp System | Production Update

Making The Xpander Clamp System | Production Update