Groovin’ on the Dance Floor

A CNC machine may be capable of placing a router in precisely the right place, and follow an exact path, but still a router is just a motor.

The real tool is the router bit – it does the real work. If you were hand carving an intricate pattern, you’d want your tools to be razor sharp, and have the variety of profiles that you need. Just because a router is a powered version of a chisel, it doesn’t stop the need to have sharp bits and correct profiles.

This is where the Amana Tool® In-Groove Engraving bits from Toolstoday.com come into their own.

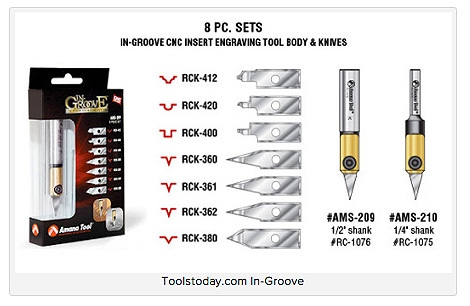

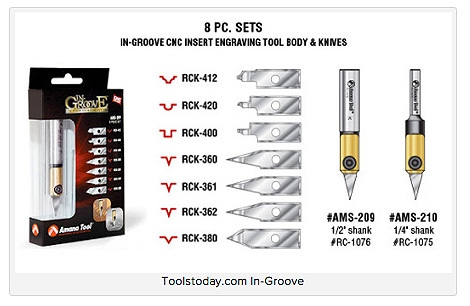

Normally, if you want a really fine tipped engraving router bit, you either have to go with tool-steel, or a particularly expensive solid carbide bit. The In-Groove bits have a real point of difference (pun intended). They have replaceable carbide tips And not only that, but a variety of profiles that fit the same router bit body.

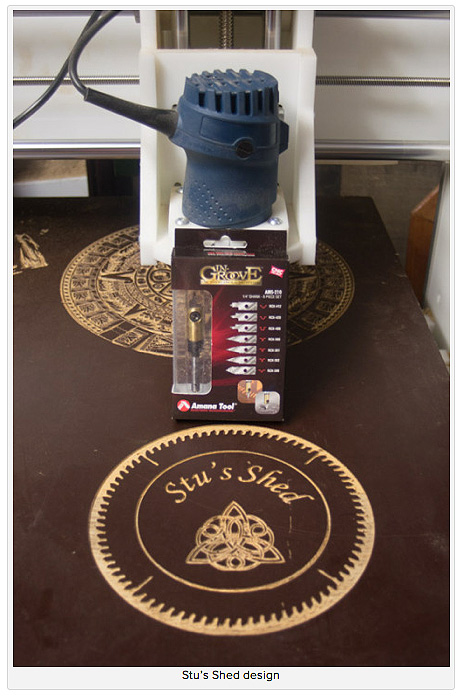

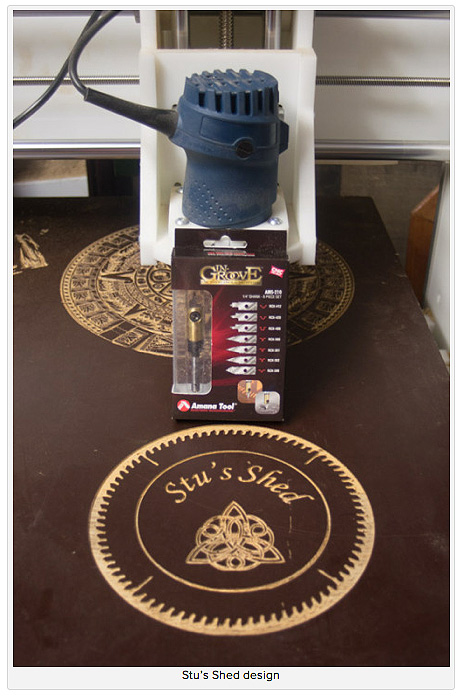

You choose either the 1/2″ or 1/4″ shank, and either just get the components you require, or get the 8 piece set which gives a good sample to start with, that you can then grow as required. If a tip becomes blunt or is broken, it is a low-cost replacement and not the entire router bit being written off.

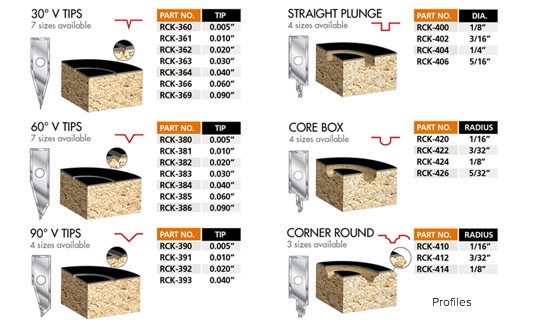

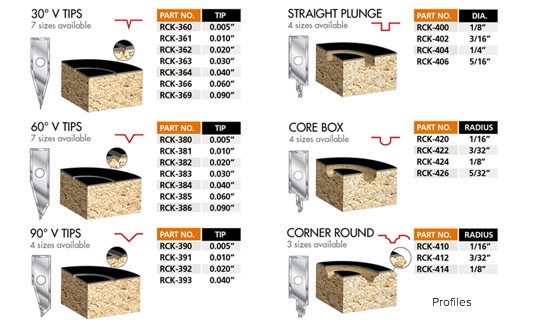

There are also a surprising variety of each profile, with different tip widths, allowing you to precisely choose a profile to match the job you are doing.

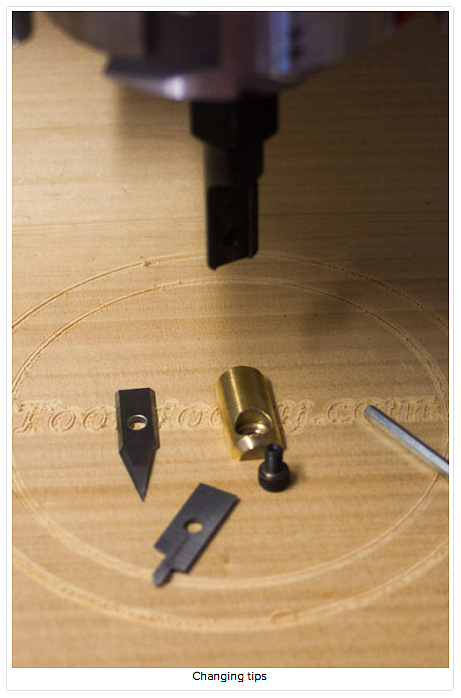

There is another real benefit to the In-Groove system that is not immediately apparent. You can change profile (effectively the same as changing router bits) without removing the bit from the router, or even having to disturb the current location of the CNC machine.

So you can set up a job with multiple paths, and like really expensive CNC machines that can change tools partway through a job, start with one profile to define edges, switch to a second for bulk clearing, then finish with a third profile that refines the design. All by undoing a single hex bolt on the router bit itself.

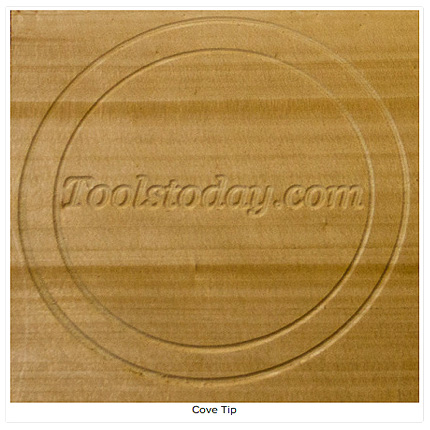

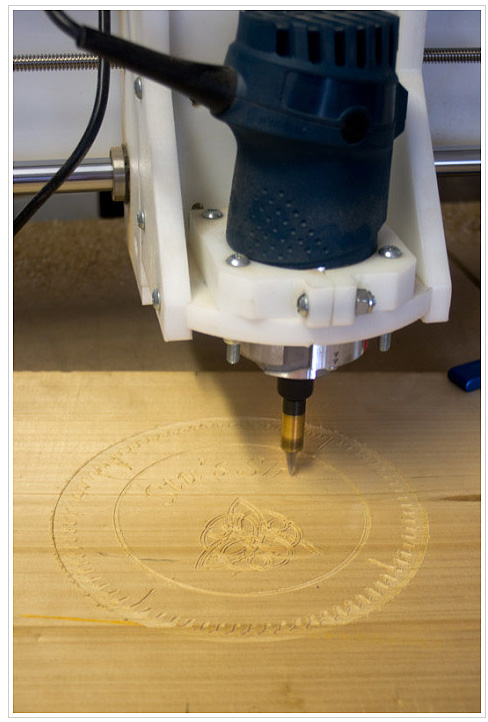

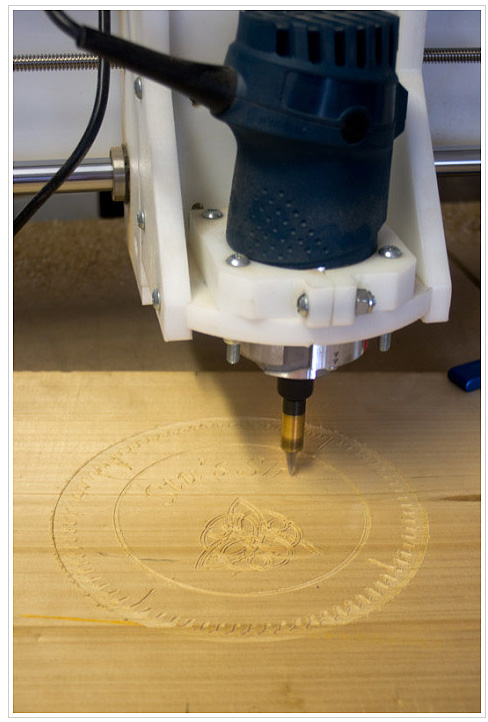

As a bit of a test (and only in pine), I quickly threw together a design to test the different profiles out. It really was simple changing tips on the fly, and matching design to bit.

As much as a V groove bit is the most commonly one used, I really liked the result of the cove tip.

I also gave a more complicated design a try, with a bit of a Celtic knot, a photo of a saw blade turned into a path, and some text on a curve.

This was done with a 30 degree V groove tip mounted. Forgot to mention, I normally choose 1/2″ shank router bits, but knowing the CNC shark router is 1/4″, that is the way I went here. The bits don’t get heavily loaded up – it is not bulk material removal after all.

The In-Groove router bits do sound like they are not running true (you develop quite an ear for that sort of thing after a while), but I didn’t see any particular problem at the router bit tip, so I suspect it is more because of some asymmetry caused by the tip retaining plate rather than the bit not running true. For any bit mounted in the CNC, I made sure they were fully inserted into the collet. No matter what the size, the router is single speed, and kicking along at 33,000 RPM.

Finally, I ran the same design onto the laminated board that I did the Mayan calendar and Japanese dragon, to see how well it came out. I could have refined it further by choosing different bits (and depth of cut) for different portions of the design, but took the simplest option – letting it run from start to finish.

This isn’t some new design for a Stu’s Shed logo, although I don’t mind the saw blade and text layout, but I’d want to replace the Celtic design with something more applicable. Perhaps the outline of a Festool Domino, or something!

If you are so inclined, see what you can come up with (Illustrator format preferred!)

So that is the Amana Tool In-Groove CNC Router Bits, from Toolstoday.com. If you have a CNC router, these are definitely worth some attention.

Originally posted on September 14th, by Stuart

Read the original article here.