PRODUCT DETAILS

Click an item to expand and learn more

-

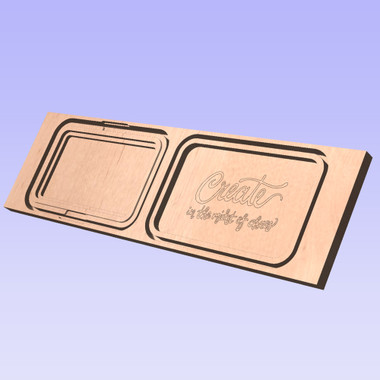

Large Wooden Jewelry Box CNC Plans, Downloadable and Customizable

Difficulty Level: Intermediate.

With this design you will be able to make a very nice, tight fitting jewelry box with an engraving inside.

This may seem like a simple project, but there are a lot of toolpaths required to get the outcome we are looking for. In this set of plans I will walk you through finding the correct offset needed for your CNC machine to achieve a tight-fitting box like this. The engraved text, included in the plans, is hand lettered by my wife, but you can certainly use any font to customize the box to add a date or add your own text. You can also size the box up or down depending on your needs as all the same principals would apply for a larger or smaller box. The largest single piece in the project is 6.375” tall x 10.125” long if you needed to break up the design to fit on your machine.

Tools used in this project:

Amana Tool 46202-K SC Spektra Extreme Tool Life Coated Spiral Plunge 1/4 Dia x 3/4 CH x 1/4 SHK 2-1/2 Inch Long Down-Cut Router Bit

Amana Tool 56142 Carbide Tipped Point Cutting Roundover 1/16 R x 9/64 D x 7/32 CH x 1/4 SHK x 2-1/4 Inch Long Router Bit for Beadboards

Amana Tool 45771-K Solid Carbide Spektra™ Extreme Tool Life Coated 30 Degree Engraving 0.005 Tip Width x 1/4 SHK x 2-1/4 Inch Long Signmaking Router Bit

Amana Tool 46315-K SC Spektra™ Extreme Tool Life Coated Spiral Plunge 1/4 Dia x 1 CH x 1/4 SHK 2-1/2 Inch Long Up-Cut Router Bit

Amana Tool 49496 Carbide Tipped Corner Rounding 1/8 R x 3/4 D x 3/8 CH x 1/4 Inch SHK w/ Lower Ball Bearing Router Bit

Ensure the tools, depth of cut, speeds and feeds are correct for your setup and the bits you’re using.

How it works

- Sign in to your ToolsToday account, consent to our terms of use, add the plans to your shopping cart and checkout.

- After confirming the payment, you will receive an email confirmation with a download link.

- The link will have a zip file in it and will contain all items in the “Included with the plans” section.

- Click the Download button and save the file to your computer.

Included with the plans

You will receive a detailed PDF with step-by-step instructions, SVG files, DXF Files, Vectric Aspire and Vectric V-Carve Pro files, both compatible with version 9 and up. The Vectric files include all toolpaths set for you.

What you have to know

- All sales are final.

- Downloaded products are non-refundable.

- You agree that these files are for personal use only.

- File may not be shared or uploaded to another website.

- You agree to not share these files in any way or form.

- You agree to not sell the finished product created by these plans nor mass produce these files.

Read More

-

-

How to Make a Jewelry Box Gift | ToolsToday CNC Video

How to Make a Jewelry Box Gift | ToolsToday CNC Video