Spoilboard CNC Router Bits – The Value Discussion

Are Spoilboard Bits Worth the Investment?

The affordability and subsequent increase in popularity of CNC machines, has meant producers like Amana Tool® have seen an upsurge in the demand for CNC cutting tools. However, we still see many people debating the value of CNC cutting tool investment, where the cost/benefit calculation isn’t always the key driver in decisions. Spoilboard CNC router bits are the perfect example as they provide much more value than you might imagine.

In this blog feature, we examine recent questions asked by several customers regarding the range of Amana Tool CNC Insert Spoilboard Surfacing, Rabbeting, Flycutter, Slab Leveler & Surface Planer router bits. The long description of such tools, gives the first clue that there could be added value!

At ToolsToday, we love to share tool experiences of our community and when it comes to spoilboard bits, then we have had a substantial amount of content sent to us. At times the best answers to tooling questions come from like-minded professionals and in this video example (below) of the Amana Tool #RC-2251, we see the incredible finish that this Solid Carbide Insert Knife CNC Spoilboard Router Bit with Scorers, 2+2 Design gives.

Doesn’t everyone seek that perfect finish?

There is some debate amongst users over the frequency of how many times they need to resurface a spoilboard and and this can often just be the difference in user types. However, this can certainly be a factor in deciding to use a cheaper standard tool or perhaps an insert spoilboard bit. An industrial shop most likely has CNC machines working flat out for 10-12 hours per day, whereas a pro-user might only use a smaller machine once or twice per week. This debate can certainly go either way, however, in this next example regardless of the user type, the ability of the spoilboard CNC router bit to perform other functions such as resurfacing reclaimed wood, starts to demonstrate the additional function and value of this type of tool, regardless of the user type.

The ability of the spoilboard CNC router bit to perform other functions such as resurfacing reclaimed wood, starts to demonstrate the additional function and value.

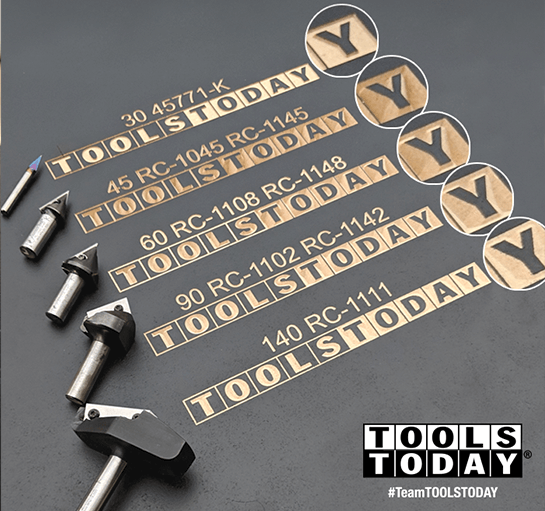

When you start to look deeply at the features and advantages of using insert tooling for functions such as spoilboard and wood resurfacing, you can also include other planing, finishing, rabbeting or slotting uses. So, what are the main common features and benefits within the range of Amana Tool solid carbide spoilboard plunging, surfacing, planing, flycutting & slab leveler bits?

- The 3-wing or 5-wing design results in a more balanced tool while running

- Capable of removing very thin layers of material, up to less than 0.001″ per pass.

- Plunge capability down to 1/4″, then start resurfacing

- Unique chamfer corner insert design creates a flawless surface

- Large cutting diameters for cutting large surface areas and surface planing

- Higher number of teeth allows for higher feed rate

- Solid carbide replacement insert knives with cutting edges that allow users to rotate the knife when one side becomes dull.

- Mini spoilboard selection for accessing tight corners

So, we can now see that the impressive functionality of this range of tools, starts to perhaps tip the balance of the value debate, particularly if you consider the number of standard router bits possibly required to carry out the same tasks. However, what about the types of material that those solid carbide knives can handle? Well, again, the range of materials is pretty impressive and when the correct insert knives are chosen, it’s possible to use the following materials:

- MDF

- Fiberboard

- HDF/LDF

- High Density Urethane (HDU Board)

- Balsa Core

- Solidwood/Softwood

- Plywood/Chipboard

- Plastic/Acrylic

- Ultra-High-Molecular-Weight Polyethylene (UHMWPE)

What if you don’t have a CNC machine, would those tools be of any use?

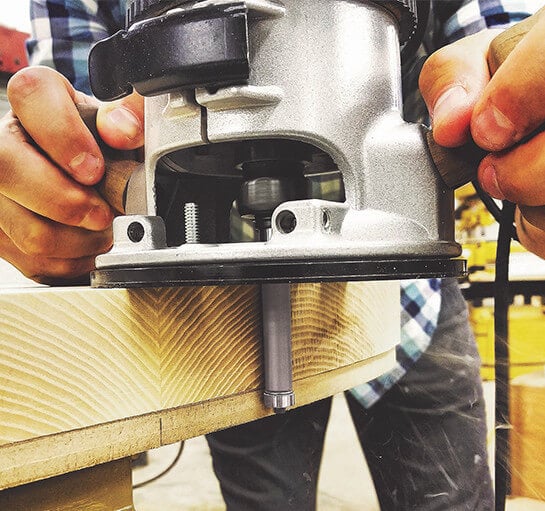

The good news is that there are a number of tools in the range that can be used with hand held routers, where you can enjoy the same results you would expect to see with a CNC machine. The example in this next video shows the incredible performance of these router bits

So, in conclusion we have only presented facts surrounding this range of spoilboard plunging, surfacing, planing, flycutting & slab leveler bits and the decision to invest remains an individual choice.

We also recommend you browse through this impressive range, look at the reviews and watch some of the videos. There can be no greater influence in a value discussion than listening to fellow professionals.