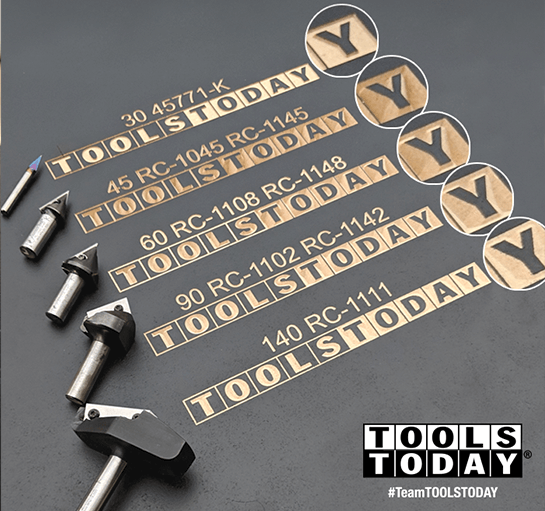

V-Groove Router Bits; 30°, 45°, 60°, 90°, & 140° Examples

Degrees of a V-Groove Router Bit

Have you ever wondered what all of the different degree V-Groove router bits do?

A v-groove router bit is often times an excellent solution for making many different signs using your CNC. You are able to select your design and the software will generate tool paths mathematically calculating its movements based on the design and the bits dimensions creating a stunning carving.

There are many different degree options when choosing a v-groove bit. In this blog feature, we will discuss what the different angles accomplish, the different styles of v-groove bits and ultimately which one is right for you.

While there are certainly more options, I will be focusing on the 30°, 45°, 60°, 90° and 140° degree v-bits in this article. I created a sign, shown above, using each of the different bits to illustrate the difference in each tool.

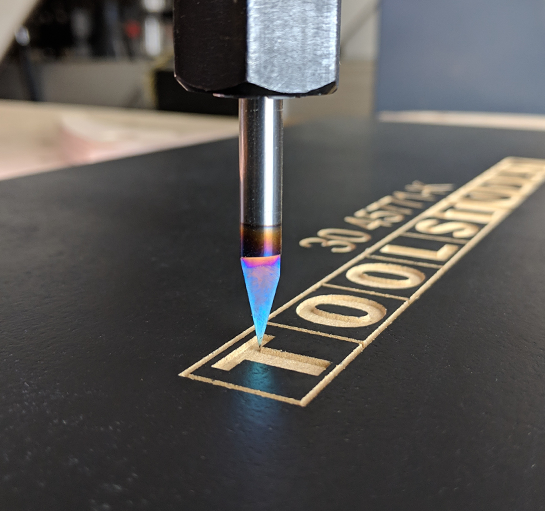

30° V-Groove Router Bits

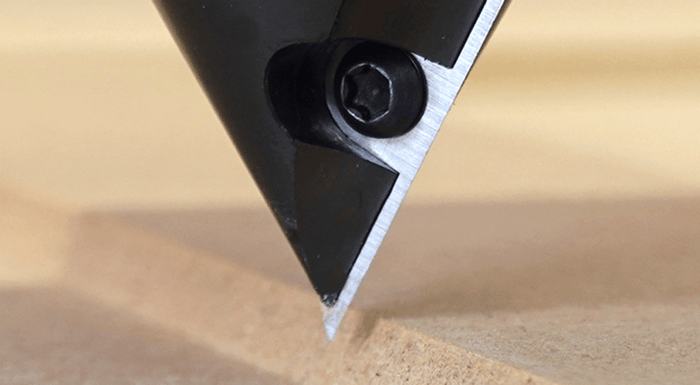

First we will start with the Amana Tool’s #45771-K 30° Solid Carbide Spektra™ Engraving bit. There is a common misconception that this bit can be treated like normal v-groove router bits, when in reality it is an engraving bit. This means that it excels in carving extremely fine detail at shallower depths. I generally recommend a .1” depth per pass using this bit as illustrated in the photo below. The bit certainly can carve deeper, but you should maintain the .1” depth per pass when using this bit.

45° V-Groove Router Bits

Next up is the Amana Tool’s #RC-1045 and #RC-1145 45° Insert V-Groove bit. You will notice in the first picture how much deeper this bit has carved than any of the others giving more contrast in the carved out area. This bit will handle the finest of details very well while carving larger areas deeper to fill the design. Being a smaller diameter it may not be able to fully cut out a design without a flat depth set.

60° V-Groove Router Bits

Which brings us right into the Amana Tool’s #RC-1108 and #RC-1148 60° Insert V-Groove bit. This is my recommendation for a general go-to bit. It is wide enough to handle a large variety of designs with ease, but still cuts deep enough to give the very cool contrast that comes with a v-carve.

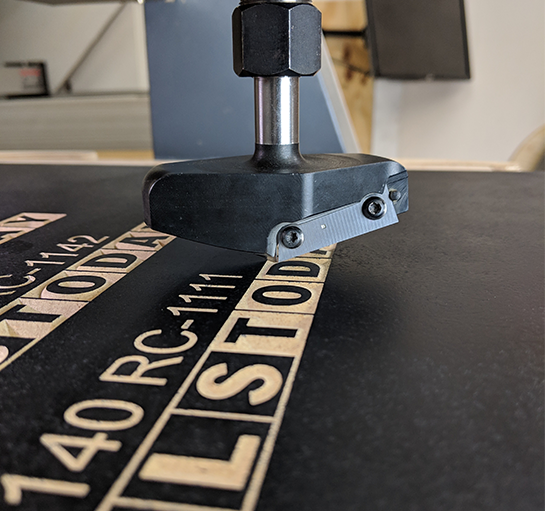

90° V-Groove Router Bits

For larger designs the Amana Tool’s #RC-1102 and #RC-1142 90° Insert V-Groove bit is a fantastic tool. It is able to cut designs over an inch wide without a flat bottom. Notice in the first picture how much shallower the cut is to fill the spaces between the letters. This provides less contrast in the cut with smaller designs like this, yet it is still able to handle finer details well.

140° V-Groove Router Bits

For the largest of designs the Amana Tool’s #RC-1111 140° Insert V-Groove bit can cut designs over 2” wide without a flat bottom. This bit handles the large details very well, but because it doesn’t need to cut very deep may not show the smaller details quite as well. Notice in the first picture how shallow the carving is, if your material isn’t perfectly flat the bit may miss smaller details due to how shallow the cut is. Large designs are definitely what this bit is meant for and it excels at it!

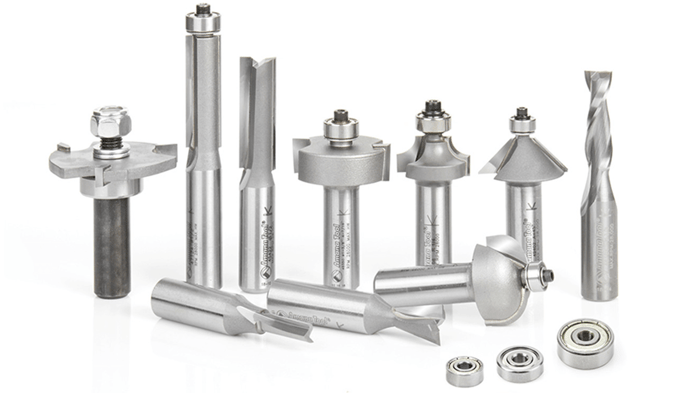

You may have noticed that all of the bits I mentioned here are either solid carbide or are the Insert V-Groove bits.

This is because these bits are of the highest quality and provide the cleanest cuts possible. If you are doing more than just a few cuts I would highly recommend investing in the Insert V-Groove tooling.

Because the inserts are not brazed onto a tool body the carbide is able to be harder providing a longer tool life and superior quality cuts, every time.

The best part is that if the insert gets dull, you can either rotate the insert for a new cutting edge, or replace it with a new inexpensive insert saving you money over time without the need to re-zero the CNC.

These Insert V-Groove bits are certainly a game changer and something I recommend everyone try on their CNC!

In conclusion, we hope this has provided you with information about how to select the right bit for your design and what the strengths of each V-Groove bit are. We encourage everyone to take a look at the Insert V-Groove lineup, read the reviews and give one of them a try. You won’t be disappointed.