PRODUCT DETAILS

Click an item to expand and learn more

-

For some years woodworkers have been taking dust collection more seriously for both work environment and health reasons. Tool manufacturers have added and improved dust collection on their equipment, pleated filters are replacing open weave bags and cyclone separators are becoming common. One critical component of the dust collection system hasn’t seen much in the way of innovation…that is, until now. Introducing Woodpeckers FULLThrottle blast gates. Our blast gates offer several unique advantages over traditional sliding valves; more efficient airflow, reduced maintenance, better fit with quick-change couplers, easier installation of flexible hose, and better mounting options.

Efficient Airflow

Inspired by the intake ports on top-fuel dragsters (where airflow restrictions are the difference between winning and losing), our engineers designed a high-efficiency butterfly valve. When the valve is open there’s only the knife edge of the gate obstructing airflow and when it’s closed, it is nearly 100% blocked with little risk of debris getting in the way of full closure. Look inside the typical steel or plastic sliding gate and you’ll see a large portion of the airway blocked by the part of the gate that doesn’t get out of the way. This not only restricts airflow, it also creates unwanted turbulence.

Reduced Maintenance

Typical blast gates have grooves for the gates to slide in. Those grooves collect chips like a magnet. Soon you have to fight the gate open and closed or stop everything and clean them out. FULLThrottle’s butterfly design eliminates the groove and the cleaning that goes with it.

Better Mounting Options

Ducts running overhead? Put your FULLThrottle blast gates with the lever facing down. Ducts on the wall? The lever can be placed on either side, the top or the bottom, whatever is convenient. Need the valve mounted directly to the machine? In addition to our in-line valve, we offer one with a flange mount. No matter which way you mount it, you won’t have gates opening when they shouldn’t or vibrating closed in the middle of your job. And if it’s in a tight spot, opening the valve doesn’t require 4-inch clearance beside the duct.

Better Fit with Quick-Change Fittings

Sometimes you don’t want to connect a hose permanently. Maybe a couple machines have to share a hose, or leaving the hose in place all the time creates a tripping hazard. We designed the fitting of the FULLThrottle to mate to every 4” quick-connect coupler we could find. No matter what brand of quick-change coupling you have on your hose, it will fit the FULLThrottle.

Easier Installation

The taper that fits quick-change couplers also makes permanent installation of flexible hose easier. With a 2-inch clamping length (more than twice the clamping area of most other blast gates) and two tapered sections, you’ll always get a good seal, no matter what brand or style of flexible 4” hose you’re using. If you need a firmer mount than just your ductwork or hose, we offer a Rack-It mounting bracket that attaches to the blast gate in seconds and provides a solid mount to the wall or ceiling.

Like all Woodpeckers products, FULLThrottle blast gates are proudly made and carefully inspected in our Strongsville, Ohio, manufacturing facility (just south of Cleveland).

Additional Info

- Enhancing dust collection systems in woodworking environments for improved work conditions and health.

- Upgrading existing dust collection setups with more efficient airflow components.

- Reducing maintenance time and effort in dust collection systems by eliminating the need for frequent cleaning of blast gates.

- Offering versatile mounting options to accommodate various workshop layouts, including overhead ducts and wall-mounted setups.

- Facilitating quick and easy changes between machines by ensuring compatibility with all 4" quick-change couplers.

- Improving the installation process of flexible hoses in dust collection systems, ensuring a secure and leak-proof connection.

- Providing a robust solution for workshops where dust collection systems need to be frequently reconfigured or adjusted.

- Ensuring a cleaner, more efficient workshop environment by minimizing airway blockages and turbulence in dust collection systems.

-

-

Download Manual Instructions

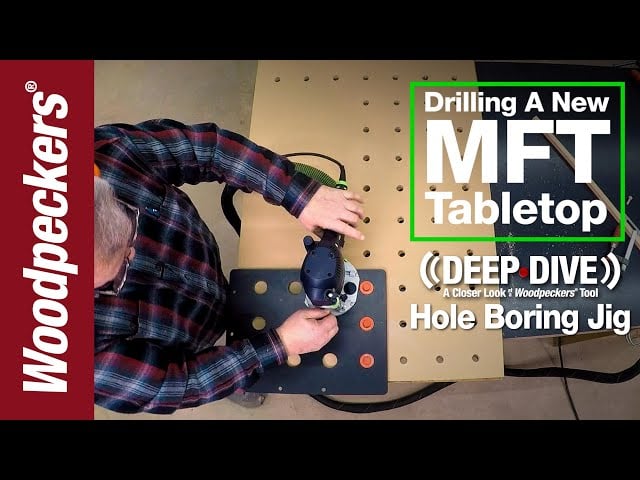

Download Manual Instructions Drilling New MFT Tabletop With Hole Boring Jig | Deep Dive

Drilling New MFT Tabletop With Hole Boring Jig | Deep Dive