Choosing the Right Circular Saw Blade for Your Project

Choosing the right circular saw blade is crucial for successful woodworking, metalworking, or masonry projects. There are various types of circular saw blades, each designed for specific materials and tasks. Understanding the differences helps you select the best blade for your needs and achieve the best results.

This guide will explore the different types of circular saw blades, the factors to consider when selecting one, and their common applications. The goal is to help you make an informed decision that best suits your project needs.

What is a Circular Saw Blade?

A circular saw blade is a tool component designed to cut through various materials. These blades are equipped with teeth around the perimeter that rotate to slice through wood, metal, and other substances. Choosing the right blade is important to achieve smooth, precise cuts for different tasks.

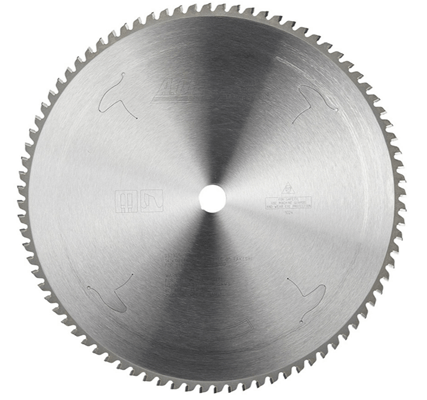

AGE Series SST355-84 Carbide Tipped Stainless Steel 14 Dia x 84T x TCG x 0 Deg x 1 Inch Bore Circular Saw Blade New line of carbide tipped saw blades rated excellent for cutting Stainless Steel Sheets, Rods, Pipes, Profiles & Extrusions with slow RPM saws.

AGE Series SST355-84 Carbide Tipped Stainless Steel 14 Dia x 84T x TCG x 0 Deg x 1 Inch Bore Circular Saw Blade New line of carbide tipped saw blades rated excellent for cutting Stainless Steel Sheets, Rods, Pipes, Profiles & Extrusions with slow RPM saws.Types of Circular Saw Blades

Circular saw blades come in a range of types, each suited for different materials and cutting techniques. For example, carbide-tipped blades offer durability and can handle tough cutting tasks. Meanwhile, high-speed steel blades are a more budget-friendly option suitable for light and general cutting tasks.

Carbide-Tipped Blades

Carbide-tipped blades are known for their long-lasting sharpness and resistance to heat. They are ideal for cutting hard woods and materials that would dull regular blades quickly. These blades offer precision and efficiency in a variety of professional applications.

High-Speed Steel Blades

High-speed steel blades are often chosen for their affordability and effectiveness in handling softer materials. While they may wear down more quickly than carbide-tipped options, they are an economical choice for general woodworking and household tasks.

Diamond-Tipped Blades

Diamond-tipped blades are designed for cutting hard materials such as concrete and stone. The diamond particles embedded in the blade ensure durability and precision when cutting through tough surfaces, making them essential for construction and heavy-duty projects.

Timberline 168-04PCD Polycrystalline Diamond (PCD) Tipped 168mm D x 4T x FT, 12 Deg, 20mm Bore, Circular Saw Blade for Fiber Cement Board The Timberline™ Polycrystalline Diamond (PCD) tipped saw blades last up to 40X longer blade life than carbide tipped blades.

Timberline 168-04PCD Polycrystalline Diamond (PCD) Tipped 168mm D x 4T x FT, 12 Deg, 20mm Bore, Circular Saw Blade for Fiber Cement Board The Timberline™ Polycrystalline Diamond (PCD) tipped saw blades last up to 40X longer blade life than carbide tipped blades.Factors to Consider When Choosing a Circular Saw Blade

When selecting a circular saw blade, it's important to consider factors such as the material you are cutting, the desired cut type (rip or crosscut), and the blade's teeth per inch (TPI). Choosing the correct blade material—whether high-speed steel, carbide, or diamond—will influence the overall quality of your cuts and the lifespan of your blade.

Material and Thickness of Saw Blades

The material used in the blade affects its durability and cutting efficiency. For instance, carbide-tipped blades are excellent for cutting dense materials, while high-speed steel blades are more suitable for lighter, less demanding cuts.

Teeth Count and Shape of Blades

The number of teeth on the blade is an important factor when considering cutting precision. Fewer teeth will generally provide a faster but rougher cut, while more teeth will create a smoother finish.

Common Uses for Different Types of Circular Saw Blades

Each saw blade type is designed to cut specific materials and provide different types of finishes. Understanding what materials you need to cut will help you choose the correct blade for your task.

Woodworking with Saw Blades

Woodworking projects require blades that can efficiently cut through different types of wood. Carbide-tipped blades are often used for their precision and durability, while high-speed steel blades are a budget-friendly option for less demanding cuts.

Metalworking with Saw Blades

For cutting metal, abrasive blades and high-speed steel blades are common choices. These blades are designed to withstand the heat and pressure associated with metal cutting, ensuring smooth and clean cuts even through tough materials like steel.

Masonry and Concrete Cutting with Saw Blades

are the go-to option for cutting through concrete, masonry, and stone. Their strong, heat-resistant composition allows them to endure the tough demands of cutting through such hard materials.

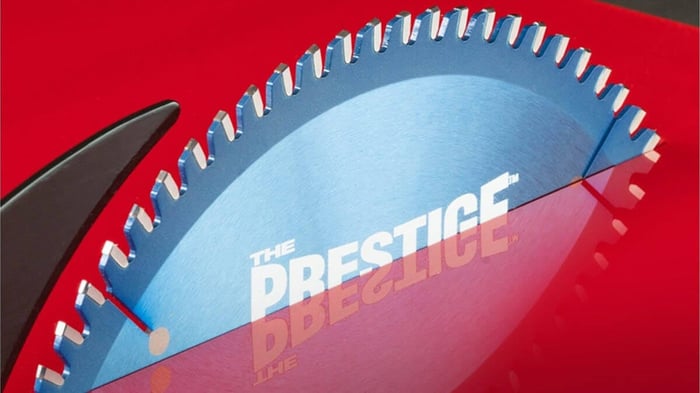

Amana Tool 610301C Carbide Tipped Electro-Blu Coated Prestige Glue Line Ripping 10 inch D x 30T TCG, 22 Deg, 5/8 Bore Circular Saw Blade Rip then glue up. With this exceptional glue line ripping saw blade, there is no need for sanding or jointing after the cut.

Amana Tool 610301C Carbide Tipped Electro-Blu Coated Prestige Glue Line Ripping 10 inch D x 30T TCG, 22 Deg, 5/8 Bore Circular Saw Blade Rip then glue up. With this exceptional glue line ripping saw blade, there is no need for sanding or jointing after the cut.Frequently Asked Questions

What are the different types of saw blades?

There are several types of saw blades, including carbide-tipped, high-speed steel, and diamond blades, each designed for specific materials and tasks.

How do I know which saw blade I need?

To choose the right blade, consider the material you are cutting, the cut type (rip, crosscut), and the blade’s teeth configuration.

What is a combination saw blade?

A combination blade can perform both rip and crosscut tasks, making it versatile for general woodworking projects.

What are specialty saw blades used for?

Specialty blades are designed for specific applications, such as cutting metal or masonry, and typically feature unique teeth or coatings for handling tough materials.

Can I use any saw blade on my saw?

No, make sure the blade you choose is compatible with your saw in terms of size and arbor fitting. Using an incompatible blade can lead to damage or safety issues.

How often should I change my saw blade?

It's important to replace your saw blade when it becomes dull or damaged to ensure optimal performance and safety in your projects.