CNC Laser Cutting & Engraving: Materials, Techniques & Tips

What Is CNC Laser Cutting & Engraving?

CNC Laser Cutting & Engraving uses a high-powered laser to cut through materials, while engraving marks the surface without cutting all the way through. Both methods are precise, with laser cutting ideal for creating shapes and parts, and engraving perfect for adding designs, logos, and text. These technologies allow for clean, smooth edges and detailed designs, making them a top choice for a wide range of applications.

Laser Cutting

Laser cutting uses a focused laser beam to cut through materials, producing clean, accurate edges. It is ideal for creating shapes, parts, and custom designs. CNC Laser Cutting & Engraving allows you to create complex shapes with precision, leaving minimal waste and reducing the need for post-processing.

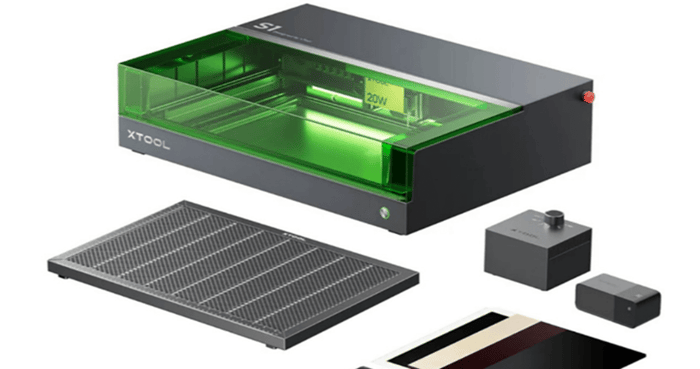

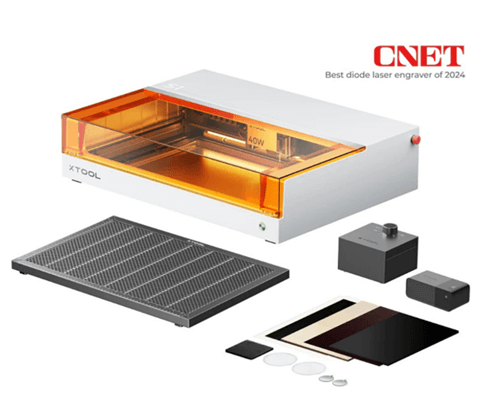

xTool S1 Enclosed Diode Laser Cutter 40W This is an all-in-one, ultra-precision laser engraver. From beginner to expert, there's something for everyone. Plus, with 4 switchable laser modules, you can upgrade at any time to excel in any scenario.

xTool S1 Enclosed Diode Laser Cutter 40W This is an all-in-one, ultra-precision laser engraver. From beginner to expert, there's something for everyone. Plus, with 4 switchable laser modules, you can upgrade at any time to excel in any scenario.Materials for Laser Cutting

- Acrylic: Acrylic is one of the most popular materials for laser cutting, offering clean cuts and smooth edges, perfect for signage and displays.

- Wood: Wood such as plywood, MDF, and hardwood are commonly cut with lasers for custom projects, furniture, and decorations.

- Plastics: Laser cutting works well with various plastics, allowing for precise, clean cuts for many applications.

MDF (Medium Density Fiberboard) MDF is made from pre-consumer recycled wood, usually sawdust from a sawmill or wood chips from lumber operations. The wood particles are mixed into a dough with a polymer binder (e.g., “glue” or “resin”) and consolidated under heat and pressure to form a panel.

MDF (Medium Density Fiberboard) MDF is made from pre-consumer recycled wood, usually sawdust from a sawmill or wood chips from lumber operations. The wood particles are mixed into a dough with a polymer binder (e.g., “glue” or “resin”) and consolidated under heat and pressure to form a panel.Laser Engraving

Laser engraving is a process where the laser marks the surface of the material without cutting through it. This method is used for adding intricate designs, logos, text, or patterns to materials like wood, acrylic, and metal. CNC Laser Cutting & Engraving machines provide excellent results for engraving, offering fine detail and depth variation to enhance your work.

xTool F1 - Fastest Portable Laser Engraver with IR + Diode Laser Personalize almost anything quickly on-the-go!

xTool F1 - Fastest Portable Laser Engraver with IR + Diode Laser Personalize almost anything quickly on-the-go!Materials for Laser Engraving

- Acrylic: Laser engraving on acrylic creates a frosted or white effect, perfect for personalized items, signs, and awards.

- Wood: Wood engraving highlights the grain, making it an excellent choice for creating custom signs, plaques, and gifts.

- Leather: Laser engraving works well on leather, making it ideal for personalizing products like wallets and belts.

Acrylic - Transparent Light Green This is transparent light green acrylic. Transparent acrylic sheets have varying degrees of light transmission, but all will allow you to see through the material. Transparent acrylic sheets are smooth and glossy on both sides.

Acrylic - Transparent Light Green This is transparent light green acrylic. Transparent acrylic sheets have varying degrees of light transmission, but all will allow you to see through the material. Transparent acrylic sheets are smooth and glossy on both sides.

Tips for Laser Engraving

- Adjust Power & Speed: Engraving generally requires lower power and faster speeds than cutting, depending on the material and desired effect.

- Depth & Contrast: The depth of the engraving can be adjusted by modifying the laser's power, affecting the contrast and detail of the design.

Common Materials for CNC Laser Cutting & Engraving

CNC Laser Cutting & Engraving can handle a wide range of materials, from soft woods to durable plastics and metals. Here's an overview of some of the most common materials used:

Materials for Cutting

- Cardboard: Ideal for packaging and prototyping, cardboard cuts easily and cleanly with a CNC laser cutter.

- Fabric: Laser cutting is perfect for fabrics, offering precise cuts without fraying the edges.

- Metal (with fiber laser): A fiber laser can cut metals like stainless steel and aluminum with high precision, making it ideal for industrial applications.

Materials for Engraving

- Wood: Laser engraving on wood creates deep, rich marks that bring out the natural grain, perfect for custom décor and products.

- Glass: Laser engraving on glass can create frosted effects, great for awards and personalizing glassware.

- Rubber: Laser engraving works well for creating custom stamps and molds from rubber.

FAQs

Can CNC Laser Cutting & Engraving be used on metals?

Yes, but with a fiber laser. CO2 lasers, commonly used for wood and acrylic, are not effective for cutting or engraving metals. Fiber lasers are specifically designed to handle metals like stainless steel and aluminum.

What thickness of acrylic can I cut with a CNC Laser Cutter?

CO2 laser cutters can typically cut acrylic up to 1/4 inch thick. For thicker acrylic, you may need a more powerful laser or slower cutting speed.

How do I clean laser-cut acrylic?

After cutting, clean acrylic with a soft cloth and a mild cleaner to remove any residue. Avoid using abrasive materials that could scratch the surface.

What materials should I avoid cutting with CNC Laser Cutting & Engraving?

Avoid cutting PVC with a laser, as it releases harmful fumes. Additionally, reflective materials like mirrors can damage the laser machine.

Conclusion

CNC Laser Cutting & Engraving is a powerful technology for creating detailed designs and parts with high precision. Whether you're cutting shapes from acrylic or engraving custom logos on wood, these machines offer the versatility to work with various materials. With proper settings and techniques, CNC laser cutters and engravers can enhance the quality of your work and streamline your production process.