Cut Cooler, Cleaner, Longer: The Spektra™ Bit Advantage

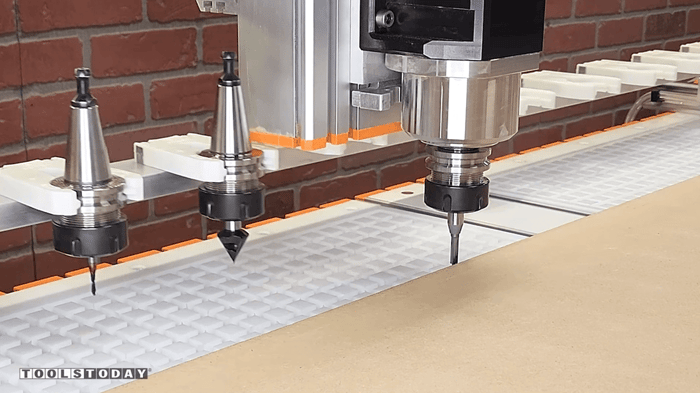

If you’ve spent time running a CNC machine, you know that not all router bits are created equal. Spektra™ bits by Amana Tool are engineered for serious performance, offering extreme heat resistance, longer tool life, and a signature nanocomposite coating that’s as functional as it is beautiful.

In this post, we’ll break down what makes Spektra bits different, which materials they’re ideal for, and how to choose the right bit for your application. We’ll also highlight some of the most popular Spektra bits among CNC users like you.

What Makes Spektra™ Router Bits Different?

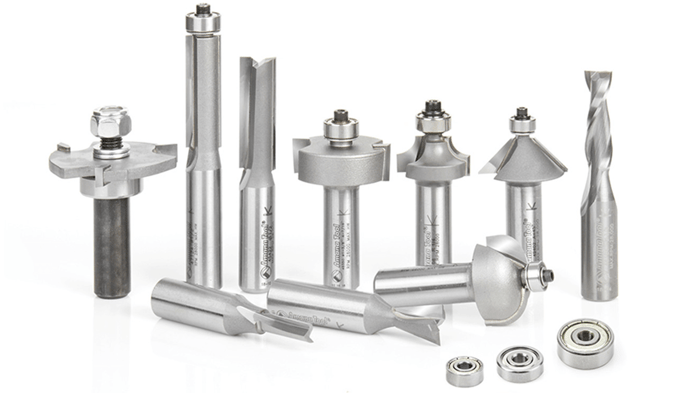

Spektra™ bits are solid carbide or carbide-tipped router bits coated with nACo® (nano-composite coating), which delivers:

- Extreme hardness for longer cutting life

- Low friction for smoother cuts and better chip evacuation

- High heat resistance—up to 1,100°F!

- Signature iridescent finish that indicates superior coating durability

These bits are designed for high-speed CNC use on materials like MDF, hardwood, plywood, plastics, composites, and even aluminum.

Spektra™ Bit Types & When to Use Them

Spektra™ bits are engineered with specific materials and machining needs in mind. Here’s a breakdown of the most popular types and what they’re best at.

Spiral Up-Cut & Down-Cut

These are your go-to bits for fast, efficient routing in wood and wood composites. Up-cut bits pull chips upward, making them ideal for deep pockets, grooves, and mortises. Down-cut bits push chips downward to prevent tear-out on the top surface—perfect for veneered plywood or melamine panels.

Use these for materials like hardwood, softwood, plywood, MDF, and particleboard. The Spektra™ coating reduces friction and heat, which extends tool life and improves surface finish.

Popular Bits:

- Amana Tool 46202-K Solid Carbide Cutting Edge Spektra Extreme Tool Life Coated Spiral Plunge 1/4" Dia x 3/4" Cutting Height x 1/4" Shank Down-Cut Router Bit

- Amana Tool 46225-K SC Spektra Extreme Tool Life Coated Spiral Plunge 1/8" Dia x 13/16" CH x 1/4" Shank Down-Cut Router Bit

Compression Spiral

Compression spirals are specially designed for double-sided laminated materials like melamine or veneered plywood. They combine up-cut flutes at the tip and down-cut flutes near the shank, delivering clean edges on both the top and bottom of the cut.

These are a favorite for cabinetry, furniture, and signs where edge quality matters. Spektra’s heat-resistant coating helps prevent chip-out and burning during long runs.

Popular Bits:

- Amana Tool 46170-K CNC SC Spektra Extreme Tool Life Coated Compression Spiral 1/4" D x 7/8" CH x 1/4" Shank 2-Flute Router Bit

- Amana Tool 46172-K CNC SC Spektra Extreme Tool Life Coated Compression Spiral 3/8" D x 1-1/4" CH x 3/8' Shank 2-Flute Router Bit

O-Flute Bits (For Plastics and Soft Metals)

O-Flute bits are designed for clean, melt-free cuts in plastics like HDPE, acrylic, polycarbonate, PVC, ABS, and soft metals like aluminum and ACM.

The name comes from the bit’s signature “O”-shaped single flute—a highly polished channel that evacuates chips efficiently while reducing heat. Spektra coating further protects the bit and the material, minimizing friction and leaving a smoother edge.

If you’re a sign maker or working with plastics and composites, O-Flutes are essential.

Popular Bits:

- Amana Tool 51411-K CNC Spektra Coated SC Spiral O Single Flute, Plastic Cutting 1/8" D x 1/2" CH x 1/4" Shank Up-Cut Router Bit with Mirror Finish

- Amana Tool 51404-K CNC Spektra Coated SC Spiral O Single Flute, Plastic Cutting 1/4" D x 3/4" CH x 1/4" Shank Long Up-Cut Router Bit with Mirror Finish

V-Groove & Engraving

Used for sign making, lettering, and decorative inlays, these bits are optimized for surface work. V-Groove bits cut crisp, angled channels—ideal for signs and panels. Engraving bits offer finer points for delicate text, logos, or detailing.

Best for wood, MDF, PVC, and aluminum composite panels (ACM). The Spektra coating resists resin buildup and extends edge sharpness, especially helpful when carving dense or resinous materials.

Popular Bits:

- Amana Tool 45634-K SC Spektra Extreme Tool Life Coated V-Groove 30 Deg x 1/4" D x 27/64" CH x 1/4" Shank 3-Flute Router Bit

- Amana Tool 45624-K SC Spektra Extreme Tool Life Coated V-Groove 60 Deg x 1/4" D x 7/32" CH x 1/4" Shank 3-Flute Router Bit

Tapered Ball Nose

Designed for 3D contouring and detailed surface carving, these bits excel in relief work, molds, and topographic maps. The taper increases strength and rigidity, reducing breakage during fine work or long tool paths.

Best used in hardwood, MDF, modeling board, and soft plastics. Spektra coating reduces heat buildup in long cuts, especially helpful in foam or soft composites where melting can be a concern.

Popular Bit:

Ball Nose

These non-tapered bits are commonly used for finish passes on 3D carvings or rounding inside corners. They’re ideal for producing smooth contours and flowing shapes in your models or signs.

Recommended for MDF, hardwood, foam board, and some plastics. The Spektra coating ensures clean cuts over longer run times and reduces tool wear on abrasive materials.

Popular Bit:

Which Spektra™ Bit Is Right for Your Material?

| Material | Recommended Spektra™ Bit Type(s) | Avoid This Mistake |

|---|---|---|

| Hardwood | Spiral Up-Cut, Compression, Ball Nose | Don’t use O-Flute bits—these are for soft plastics, not dense wood fibers. |

| Plywood / MDF | Compression Spiral, Down-Cut, V-Groove | Up-cuts can tear out top veneer—use compression for clean edges. |

| Melamine / Laminated Boards | Compression Spiral | Standard spiral bits can chip laminate—compression gives a clean finish. |

| Acrylic / PVC / HDPE | O-Flute (Single Flute) | Don’t use multi-flute bits—heat buildup can melt the material. |

| Aluminum / ACM | O-Flute (Polished Single Flute) | Avoid uncoated bits—friction can cause chip welding or breakage. |

| Foam / Modeling Board | Tapered Ball Nose, Ball Nose | Using standard end mills can crush foam instead of carving cleanly. |

| Signboard (PVC, HDU, ACM) | V-Groove, Engraving, O-Flute | Don’t overlook chip evacuation—poor clearing leads to rough edges. |

Ready to Upgrade Your CNC Game?

This list only scratches the surface of what is available - for more information, check out the Spektra Brochure.

Explore the full Spektra™ router bit collection on ToolsToday and get sharper cuts, cooler operation, and longer tool life starting today.

FAQs

What makes Spektra™ bits different from standard router bits?

Spektra™ bits by Amana Tool are coated with a nano-composite called **nACo®**, which gives them a rainbow-like finish. This coating offers extreme hardness, reduces friction, and resists heat up to 1,100°F. The result is a bit that stays sharp longer and performs more cleanly—especially under high-speed CNC conditions.

Do Spektra™ bits work on all materials?

Not every bit works for every material—but within the Spektra™ line, you'll find options for wood, MDF, plastics, aluminum composites, and foam. Each geometry is optimized for specific materials (for example, O-Flute bits for plastics, compression bits for plywood). Choosing the right bit type is key to getting the best cut and tool life.

Will the colorful Spektra™ coating wear off?

The iridescent coating will fade or discolor with use, especially where the bit contacts the material most. That’s completely normal. The coating is still doing its job—reducing friction and protecting the cutting edge. Even after the visible color fades, the underlying benefits of the coating remain in place for a substantial portion of the bit’s life.

Are Spektra™ bits worth the higher cost?

Absolutely—if you're using your CNC machine regularly. Spektra™ bits often **outlast uncoated carbide by 2–3 times**, especially in demanding materials like laminated plywood or plastic. That means fewer tool changes, cleaner results, and more time cutting instead of troubleshooting. Over time, they pay for themselves.

Can I use Spektra™ bits in a handheld router?

Some Spektra™ bits—like V-Groove or Straight Plunge bits—can be used in a handheld router. But many are optimized for CNC use, especially O-Flute and compression spirals, which perform best at consistent speeds and feeds. Always check your tool’s RPM limits and shank compatibility before use.