Getting Started with CNC: Your Guide to CNC on a Budget

If you're a maker or DIY enthusiast, you've probably heard of CNC machines. These computer-controlled machines are used for precision cutting, carving, and shaping a variety of materials, from wood to metal. But if you're just starting out, you may not know where to begin, or how to navigate CNC on a budget. In this article, we'll provide a comprehensive guide to getting started with CNC, even if you're on a budget.

Table of Contents

- What is CNC?

- Advantages of CNC Machines

- Types of CNC Machines

- CNC on a Budget: How to Get Started

- CNC Software

- Choosing the Right Cutting Tool

- CNC Safety Tips

- Common CNC Mistakes to Avoid

- CNC Project Ideas

- Conclusion

- FAQs

1. What is CNC?

CNC stands for Computer Numerical Control. This technology uses a computer program to control the movement of a cutting tool. The machine translates the code into precise movements, allowing for accurate cuts and shapes. Essentially, CNC machines automate and enhance traditional cutting and carving processes, making them faster and more precise.

2. Advantages of CNC Machines

CNC machines offer several advantages over traditional manual cutting methods:

- Precision: CNC machines can make precise cuts and shapes with consistent accuracy.

- Efficiency: CNC machines can work quickly and tirelessly, reducing production time and costs.

- Customization: CNC machines allow for customization and personalization of designs.

- Repetition: CNC machines can repeat the same cuts and shapes with exact precision, making them ideal for mass production.

3. Types of CNC Machines

There are several types of CNC machines, each designed for specific applications. Some of the most common types include:

- CNC Routers: Used for cutting and shaping wood, plastics, and other soft materials.

- CNC Mills: Used for cutting and shaping metal, capable of making complex shapes and cuts.

- CNC Lathes: Used for turning and shaping cylindrical objects, such as pipes and rods.

- CNC Laser Cutters: Use a laser to cut vinyl sheets and more with precision.

- Plasma Cutters: Are not typically budget-friendly, but Stepcraft makes plasma-table attachments for their CNC routers.

4. CNC on a Budget: How to Get Started

CNC machines can be expensive, but there are several ways to get started with CNC on a budget:

DIY CNC Machines

If you're handy with tools and have some technical know-how, you can build your own CNC machine. Many online resources and tutorials are available, as well as kits and plans that you can purchase. This can be a cost-effective option, but it requires some time and effort to build and set up the machine.

Low-Cost CNC Machines

Several low-cost CNC machines are available on the market, ranging from a few hundred dollars to a few thousand dollars. These machines may not have all the features of high-end machines, but they are capable of making precise cuts and shapes. Some popular low-cost CNC machines include the Shapeoko, the X-Carve, and the MillRight CNC.

Renting a CNC Machine

Another option is to rent a CNC machine from a local makerspace or fabrication shop. This can be a cost-effective option if you only need to use the machine for a specific project. Plus, you'll have access to more advanced machines and tools than you might have at home.

5. CNC Software

To create designs for your CNC machine, you'll need software that can generate the code the machine will use to cut and shape your material. Some popular CNC software options include:

- Vectric Aspire and Vectric VCarve: A powerful software that allows you to create 3D models and generate tool paths for CNC machines.

- SketchUp: A user-friendly software that allows you to create 2D and 3D designs for CNC machines.

- Carbide Create: A free software that allows you to create 2D designs and generate tool paths for Carbide 3D machines such as Shapeoko.

- Easel: A free, web-based software that allows you to create designs and generate tool paths for X-Carve and Carvey machines.

When choosing CNC software, consider your skill level, the complexity of your designs, and the type of machine you're using.

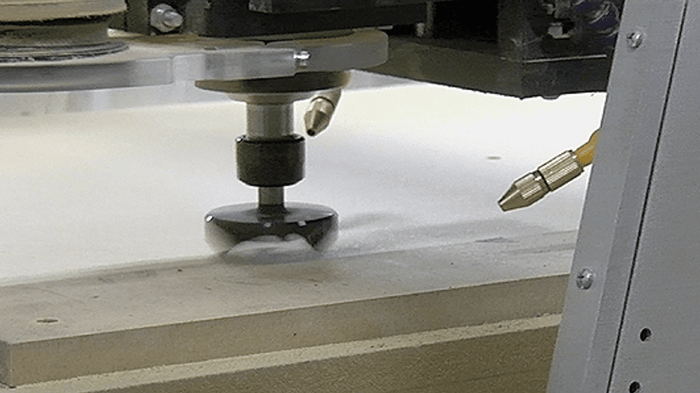

6. Choosing the Right Cutting Tool

Choosing the right cutting tool is crucial for achieving precise cuts and shapes with your CNC machine. Here are some factors to consider:

- Material: The type of material you're cutting will determine the type of cutting tool you need.

- Speed: The speed of the cutting tool should be appropriate for the material and the type of cut.

- Diameter: The diameter of the cutting tool should be appropriate for the size of the cut and the precision required.

- Coating: Coatings can help extend the life of your cutting tool and improve performance.

At ToolsToday we sell the full line of Amana CNC Router Bits, including Spektra, all in-stock and ready to ship. Free shipping on all orders over $49. (OK, shameless plug over:)

7. CNC Safety Tips

As with any power tool, safety should be a top priority when using a CNC machine. Here are some safety tips to keep in mind:

- Wear safety glasses or goggles to protect your eyes from flying debris.

- Keep loose clothing, jewelry, and long hair away from the machine.

- Do not touch the moving parts of the machine while it's in operation.

- Always use a dust collection system to reduce the risk of inhaling harmful dust and debris.

8. Common CNC Mistakes to Avoid

There are several common mistakes that beginners make when using a CNC machine. Here are some tips to help you avoid these mistakes:

- Double-check your measurements and settings before starting the machine.

- Start with a simple design and work your way up to more complex designs.

- Use proper tool paths to avoid cutting errors.

- Don't overload the machine with too much material or try to make cuts that are too deep.

9. CNC Project Ideas

Once you've mastered the basics of CNC, the possibilities are endless. Here are some project ideas to get you started:

- Cutting custom shapes and designs for woodworking projects.

- Engraving designs and logos onto metal or plastic.

- Creating custom parts for mechanical or electronic projects.

- Making personalized gifts, such as engraved cutting boards or coasters.

10. Conclusion

CNC machines are a powerful tool for makers and DIY enthusiasts, offering precision, efficiency, and customization. While they can be expensive, there are several ways to get started on a budget, from building your own machine to renting one from a local makerspace. With the right tools, software, and safety precautions, you can create a wide range of projects using a CNC machine.

11. FAQs

- How much does a CNC machine cost?

CNC machines can range from a few hundred dollars to tens of thousands of dollars, depending on the size, features, and precision of the machine. - Can I build my own CNC machine?

Yes, there are many online resources and tutorials available for building your own CNC machine. - What materials can be cut with a CNC machine?

CNC machines can cut a wide range of materials, including wood, metal, plastics, and even some types of stone. - What is the difference between a CNC router and a CNC mill?

CNC routers are typically used for cutting and shaping softer materials, while CNC mills are used for cutting and shaping metal. - Is using a CNC machine safe?

Like any power tool, using a CNC machine comes with some risks. However, with proper safety precautions, such as wearing safety glasses and avoiding loose clothing, the risks can be minimized.

In conclusion, getting started with CNC can be a daunting task, but it doesn't have to break the bank. Whether you choose to build your own machine, invest in a low-cost CNC machine, or rent one from a local makerspace, there are plenty of options for getting started on a budget. With the right software, cutting tools, and safety precautions, you'll be well on your way to creating precision cuts and shapes in a variety of materials.