How to Choose the Right Countersink Bit for Woodworking

Table of Contents

- What a Countersink Bit Actually Does

- Why Your Countersink Choice Matters

- Types of Countersink Bits (and When to Use Each)

- What to Consider Before You Buy

- How Bit Design Affects Performance

- Quick Picks Based on Your Use Case

- Beginner Tips for Better Countersinking

- What to Expect from Better Countersinks

- Wrap-Up: Choose Based on Your Workflow

- FAQs

What a Countersink Bit Actually Does

A countersink bit is designed to help screws seat cleanly and consistently in wood. In most woodworking countersink systems, you’re doing two jobs in one:

- Drilling a pilot or clearance hole (so the screw shank and threads don’t force the wood apart)

- Cutting a conical recess (so a flat-head screw’s cone-shaped underside can sit flush with—or slightly below—the surface)

This matters because most wood screws have a conical head. If the recess doesn’t match the screw head, the screw can crush surface fibers, sit proud, or drive unevenly.

Bottom line: A good countersink isn’t just about the cone. The drill portion (sharpness, geometry, chip evacuation) and the countersink portion (clean cutting edges) both affect results—especially in hardwoods and plywood.

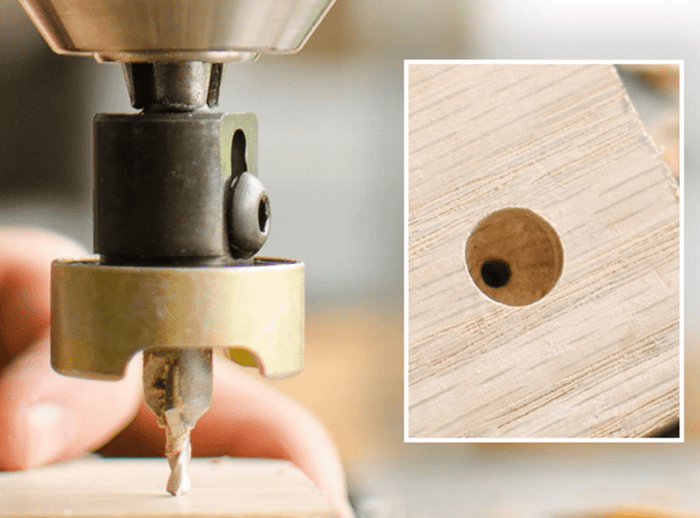

The Amana Tool 55227 Carbide-Tipped No-Mar Countersink features an adjustable, heavy-duty, revolving depth-stop with a no-thrust ball bearing for quick and easy adjustment of the countersink depth without scratching or burning surfaces.

The Amana Tool 55227 Carbide-Tipped No-Mar Countersink features an adjustable, heavy-duty, revolving depth-stop with a no-thrust ball bearing for quick and easy adjustment of the countersink depth without scratching or burning surfaces.Why Your Countersink Choice Matters

Most “bad countersink results” come from a few predictable causes—often related to tool design and sharpness, not just technique. You might notice:

- Burn marks inside the countersink

- Fuzzy or torn fibers around the rim

- Inconsistent depth from hole to hole

- Surface marring (from a stop collar contacting the wood)

A better countersink setup helps you:

- Reduce splitting by providing space for the screw and guiding it straight

- Improve fit so screw heads sit cleanly and consistently

- Control depth for repeatable, “production-grade” results

- Minimize heat by cutting efficiently and clearing chips

Types of Countersink Bits (and When to Use Each)

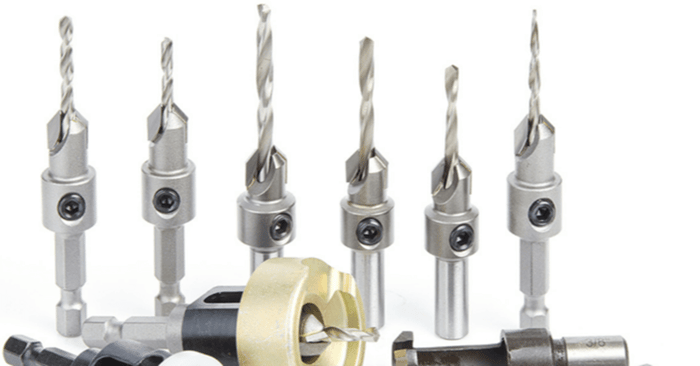

1) Standard Countersink Bits

This is the simplest style: a conical cutter with no built-in depth stop.

Pros

- Simple and affordable

- Great control on a drill press (where depth can be set mechanically)

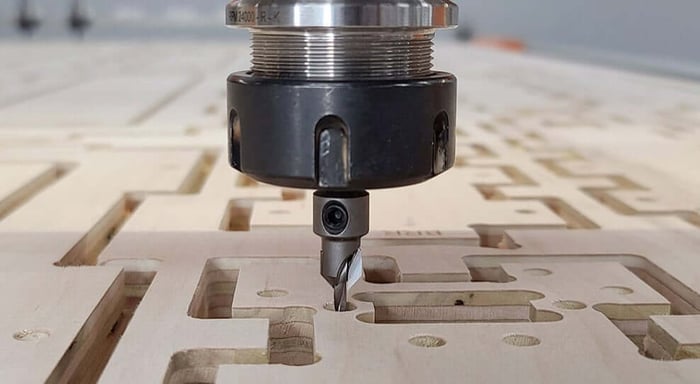

- Commonly used in CNC applications (especially round-shank versions) where depth is controlled by the machine, not a physical stopper

Cons

- Depth control is “by feel” when using a hand drill

- Like any cutting tool, dull edges, high RPM, or lingering in one spot can generate heat

Best for

- Occasional DIY projects

- Drill press work

- CNC workflows (round shank versions) where depth is programmed

Amana Tool 55264 Carbide Tipped Countersink Quick Release Hex Shank With Slow Spiral, Includes High-Speed Steel (HSS) Fully Ground Drill

Amana Tool 55264 Carbide Tipped Countersink Quick Release Hex Shank With Slow Spiral, Includes High-Speed Steel (HSS) Fully Ground Drill2) Countersink Bits with Depth Stops (Collars)

These include a collar (stopper) that limits how deep the countersink cuts. It’s a go-to choice for consistent, repeatable results—especially when drilling freehand.

Pros

- More consistent depth from hole to hole

- Great for repetitive work

- When designed properly, helps reduce surface marring

Cons

- Requires a quick setup to dial in depth

- Typically costs more than a basic countersink

Best for

- Hand drill use

- Finish woodworking

- Projects with many identical holes

Revolving stoppers matter. Higher-quality stoppers are designed to stop turning when they touch the wood. This helps reduce surface marring while still providing consistent depth. (And yes—if you’re using a countersink without a stopper, surface marring from a collar isn’t a concern at all.)

Amana 55296 Carbide Tipped Countersink w/Adjustable Low Friction Depth-Stop with adjustable low-friction depth-stop helps produce clean hole edges while allowing chips to clear effectively. Includes Fully-Ground HSS Replacement Drill Bit.

Amana 55296 Carbide Tipped Countersink w/Adjustable Low Friction Depth-Stop with adjustable low-friction depth-stop helps produce clean hole edges while allowing chips to clear effectively. Includes Fully-Ground HSS Replacement Drill Bit.3) Countersink + Plug Cutter Sets (Screw Concealment)

These systems include a plug cutter so you can drill, countersink, and then cut a matching wooden plug to conceal the screw hole for a cleaner finish.

Pros

- Furniture-grade finished look

- Excellent for visible joinery and cabinetry

Cons

- More specialized (not necessary for most basic projects)

- Usually requires extra steps (glue-in plug, trim/plane flush, sand)

Best for

- Fine woodworking and furniture builds

- When you want hidden screws

What to Consider Before You Buy

1) How precise does your countersinking need to be?

If finish quality matters—especially on visible surfaces—a depth-stop design can reduce frustration and improve consistency.

2) Are you using a drill press or a hand drill?

Hand drills make it easier to over-cut or apply uneven pressure. Depth control features can be especially helpful when drilling freehand.

3) How often do you countersink?

If you countersink rarely, a standard countersink may be enough. If you countersink often (especially in batches), a depth-stop design can pay off in time saved and repeatability.

4) What type of wood are you working with?

Hardwoods (like maple or oak) and plywood tend to reveal poor geometry quickly. Better-designed bits slice fibers more cleanly and reduce tear-out.

How Bit Design Affects Performance

Cutting Edge Quality

Sharper, well-ground edges slice wood fibers rather than crushing them. That typically means less heat, cleaner walls, and smoother entry edges.

Geometry and Flutes (Chip Evacuation)

Chip evacuation matters more than many beginners realize. Packed chips increase friction and heat, which can lead to scorching and rough edges. Premium countersinks combine sharp cutting geometry with flute designs that clear chips efficiently for smoother drilling.

Depth Stop Collar / Bearing Design

Depth stops help with repeatable depth. Designs vary, and the difference shows up in both price and feel.

- Set-screw collar (depth stop collar): typically the more economical option; effective but can create more friction depending on design and setup.

- Bearing / low-friction designs: smoother contact and reduced friction at the wood surface, helping minimize marring during repetitive use.

Carbide vs High-Speed Steel (HSS)

Carbide tipped countersinks are a major upgrade for many woodworkers because carbide stays sharp longer and maintains a clean cutting edge—especially in hardwoods and sheet goods. HSS can work well for lighter use, but it generally dulls sooner, which can increase heat and reduce cut quality over time.

Also remember: many countersink systems combine a carbide countersink with a drill bit. The quality and sharpness of the drill portion matters for smooth drilling, clean chip evacuation, and reduced heat.

Quick Picks Based on Your Use Case

- Occasional DIY work: Standard countersink bit

- Hand-drilling lots of holes: Adjustable depth-stop / no-mar countersink

- Finish woodworking (appearance matters): Depth-stop + high-quality cutting geometry

- Plug-style screw concealment: Countersink + plug cutter set

- Mostly drill press work: Standard or depth-stop (both can work well)

Beginner Tips for Better Countersinking

- Use sharp tools. Dull edges create friction, heat, and tear-out.

- Let the bit cut. Steady pressure beats forcing the tool.

- Avoid long pauses while spinning. Hesitation builds heat quickly.

- Test on scrap. Especially when switching wood species or screw sizes.

- Check screw fit early. You’re aiming for a clean seat—not a crater.

What to Expect from Better Countersinks

Upgrading to a better countersink (sharper cutting edges, better geometry, better depth control) typically gives you:

- Clean entry holes—even in hardwood

- Minimal burning or tear-out

- Consistent depth across multiple holes

- Less guesswork when using a hand drill

Wrap-Up: Choose Based on Your Workflow

There’s no single “perfect” countersink for every job—but there is a best choice for your workflow.

If you’re just starting, choose a countersink system that helps you control depth and cut cleanly. As your projects become more finish-focused (or more repetitive), an adjustable, revolving, low-friction depth stop can save time and improve consistency.

And remember: a countersink is only as good as its cutting edges—both the countersink cutter and the drill portion that forms the pilot/clearance hole.

FAQs

What is a countersink bit used for in woodworking?

A countersink bit creates a conical recess that allows a screw head to sit flush with or slightly below the surface of the wood.

What causes burning when using a countersink bit?

Burning is usually caused by friction from dull cutting edges, poor geometry, packed chips, or pausing too long while the bit is spinning.

Are countersink bits with depth stops better for beginners?

Yes. Depth-stop countersinks make it easier to control cutting depth and reduce surface marring, especially when using a hand drill.

What’s the difference between carbide and HSS countersink bits?

Carbide countersink bits stay sharp longer and cut cleaner, particularly in hardwoods. HSS bits work well for lighter use but dull faster.

Do I need a drill press to get clean countersinks?

No. A drill press helps with consistency, but clean countersinks can be achieved with a hand drill using sharp bits and proper depth control.

Why do some countersink bits leave fuzzy edges or tear-out?

Tear-out usually happens when the bit crushes wood fibers instead of slicing them cleanly, often due to poor cutting geometry or dull edges.

How do I choose the right countersink bit for my project?

Choose based on how often you countersink, whether you use a hand drill or drill press, the type of wood, and how important surface finish is.

Which countersink should I buy for woodworking?

For occasional woodworking, a standard carbide countersink bit with sharp cutting edges is a reliable choice. If you need consistent depth and cleaner surface results — especially with a hand drill or repetitive holes — a countersink with an adjustable depth stop and low-friction collar is often easier to use and produces more repeatable results.