Kerfing Basics: Bend and Shape Wood Like a Pro

Kerfing Techniques: Elevating Your Woodworking Projects

Kerfing is a key technique in woodworking, allowing you to bend wood by making precise cuts (kerfs) that increase flexibility without compromising strength. It’s especially useful in creating curved shapes for furniture, cabinetry, and even boat building.

What is Kerfing?

Kerfing involves making a series of cuts in wood to make it flexible. This technique enables woodworkers to bend and shape wood that would otherwise resist bending, expanding the design possibilities for both aesthetic and functional pieces.

Woods like maple, poplar, and plywood are ideal for kerfing, offering a balance of flexibility and strength. This method is often used to create curved furniture or architectural elements.

Benefits of Kerfing,

Kerfing offers several benefits, including increased flexibility, strength, and reduced material waste.

1. Improved Flexibility and Strength

By cutting precise kerfs, wood becomes flexible while retaining its structural integrity. For example, boat builders use kerfing to create curved ribs, while furniture makers use it for items like chair backs.

2. Reduced Material Waste

Kerfing minimizes waste by allowing you to use wood more efficiently, reducing offcuts and maximizing material usage. Thoughtful planning and proper tools further enhance this benefit.

Essential Tools for Kerfing

For successful kerfing, you’ll need the right tools. A table saw is excellent for straight cuts, while band saws help with more irregular shapes. A router can add decorative details to your kerfs.

Recommended Materials

Plywood, maple, and walnut are commonly used for kerfing. These woods offer flexibility and strength, with laminated materials being especially useful for intricate designs.

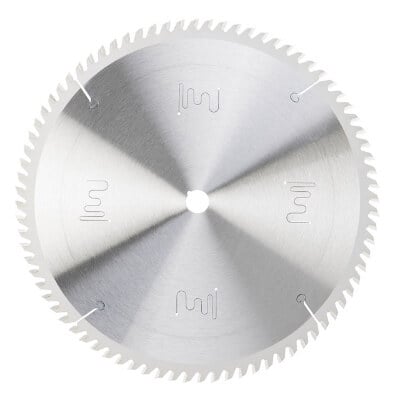

Carbide-tipped teeth provide extended durability and performance. Amana Tool TB10800 Carbide Tipped Thin Kerf Trim 10 Inch D x 80T ATB, 10 Deg, 5/8 Bore, Circular Saw Blade. Thin kerf design ensures smooth, clean cuts with minimal waste.

Carbide-tipped teeth provide extended durability and performance. Amana Tool TB10800 Carbide Tipped Thin Kerf Trim 10 Inch D x 80T ATB, 10 Deg, 5/8 Bore, Circular Saw Blade. Thin kerf design ensures smooth, clean cuts with minimal waste.

Types of Kerfing Techniques

The two main kerfing techniques are straight kerfing and curved kerfing, each suited for different woodworking needs.

Straight Kerfing

Straight kerfing involves making uniform cuts along a straight line to introduce controlled bending. This technique is ideal for furniture and cabinetry projects.

Curved Kerfing

Curved kerfing requires more skill but allows for elegant, sweeping curves in wood, making it perfect for complex designs like rocking chairs or decorative panels.

Troubleshooting Common Kerfing Issues

Common problems in kerfing include uneven cuts and wood breakage. To avoid these, use sharp tools, precise measurements, and even pressure when cutting.

Fixing Uneven Kerfing

Uneven kerfing can be corrected by adjusting your cutting angles and ensuring each kerf is consistent in depth and spacing. Use a jig for stability and check your blade sharpness regularly.

Dealing with Breakage

Breakage often occurs if the cuts are too deep or irregular. Prevent this by carefully spacing kerfs and using clamps or bending forms to control the bend.

Amana Tool’s Prestige Series Carbide Tipped Fine Cut-Off and Crosscut Saw Blades feature ElectroBlu™ Non-Stick Coating, a micron-thin translucent coating on the entire blade to help optimize performance, prevent corrosion and resin build-up. Ideal for cutting materials with fragile surface layers, like veneers and laminates. High tooth count yield smooth finishes. The hook angle provides effortless feeding. The triple chip tooth opens a narrow kerf, and the raker widens it.