SST MEGAFLOW: Ultimate Air Filtration for CNC Machines

Introduction

Maintaining clean air and proper air pressure is essential for the performance and longevity of CNC machines. The SST MEGAFLOW 3 Stage Filtration and Regulation System is designed to provide clean air and optimal pressure for CNC machines, ensuring efficiency and extending the lifespan of your equipment.

3 Stage Filtration Overview

The SST MEGAFLOW system uses a three-stage filtration process to improve air quality. It includes pre-filters, HEPA filters, and activated carbon filters. These components capture dust, fine particles, and harmful gases, ensuring clean air in the workspace and protecting CNC machines.

- Stage 1: Pre-filter: Captures larger particles like dust and debris.

- Stage 2: HEPA Filter: Removes 99.97% of fine particles, improving air purity.

- Stage 3: Activated Carbon Filter: Absorbs oil vapors and odors.

The SST filtration system is a Mega-Tough 3-Stage Shop Air Filter & Regulator With an Aluminum Monoblock Body and Premium Hardware, designed to last a lifetime.

The SST filtration system is a Mega-Tough 3-Stage Shop Air Filter & Regulator With an Aluminum Monoblock Body and Premium Hardware, designed to last a lifetime.The Importance of Air Filtration for CNC Machines

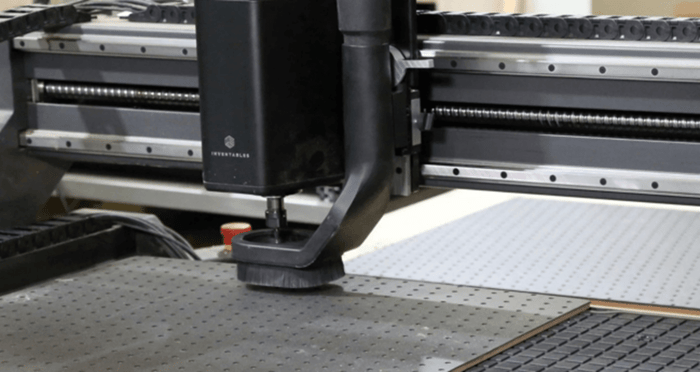

Air filtration is crucial to protect CNC machines from dust and contaminants that could impair performance. Proper filtration reduces wear, extends machine lifespan, and ensures operator safety by maintaining a clean workspace.

Contaminant Impact on Machine Performance

Contaminants such as dust, metal shavings, and oil mist can degrade CNC performance, resulting in higher maintenance costs and downtime. The SST MEGAFLOW system helps eliminate these pollutants, reducing the need for frequent repairs and improving efficiency.

Case Study: Reduced Maintenance Costs

In a large machining facility, the introduction of an advanced filtration system reduced maintenance frequency and downtime by 30%, demonstrating the cost-effectiveness of a clean working environment.

MEGAFLOW - 3 Stage Air Filtration and Regulation System Patent Pending Design features 3/4” Supply Input and Regulated Output Ports, Perfect for Whole Shop Air Filtration.

MEGAFLOW - 3 Stage Air Filtration and Regulation System Patent Pending Design features 3/4” Supply Input and Regulated Output Ports, Perfect for Whole Shop Air Filtration.Stage 1: Pre-Filtering

The pre-filter captures larger particles before they reach finer filters, extending the lifespan of the entire system and improving air quality.

Stage 2: Coalescing Filter

The coalescing filter removes liquid aerosols and oil vapors from the air, preventing these contaminants from damaging CNC machinery and maintaining air quality.

Stage 3: Activated Carbon Filter

The activated carbon filter adsorbs oil vapors and odors, ensuring that clean and fresh air is recirculated into the workspace, improving both air quality and operator safety.

Regulating Air Pressure

Proper air pressure management is critical to ensure that the filtration system works efficiently and CNC machines perform at their best. Monitoring and maintaining stable air pressure can prevent operational disruptions and costly repairs.

Installation and Maintenance

For optimal performance, it's important to follow the manufacturer's installation and maintenance guidelines. Regularly replacing filters and monitoring airflow will maximize system efficiency and longevity.

MEGAFLOW - 3 Stage Air Filtration and Regulation System EASY-VIEW FILTER CANISTERS: Shatterproof Polycarbonate Canisters House The Oversized Filter Elements, Allowing You to Visually Inspect Filter Health, Water Removal, And Air Processing.

MEGAFLOW - 3 Stage Air Filtration and Regulation System EASY-VIEW FILTER CANISTERS: Shatterproof Polycarbonate Canisters House The Oversized Filter Elements, Allowing You to Visually Inspect Filter Health, Water Removal, And Air Processing.Frequently Asked Questions

What is SST MEGAFLOW?

SST MEGAFLOW is a three-stage air filtration and regulation system designed for CNC machines. It ensures clean air and optimal pressure for efficient machine operation.

How often should I replace the filters?

Filter replacement should be done every 6-12 months, depending on usage and air quality in your facility.