PRODUCT DETAILS

Click an item to expand and learn more

-

There’s a “light bulb moment” in most woodworkers’ careers when they figure out that cutting to a line can never be as quick or as consistent as cutting to a stop. Then the pursuit begins for the perfect stop. Everyone wants a stop that’s easy to set, doesn’t move, and can flip out of the way without losing position. Add in the ability to make very fine adjustments, and you’ve got what most woodworkers would call an ideal stop. Now, make it simple to adapt to almost any miter saw and you have Woodpeckers newest tool, the StealthStop.

StealthStop is a new patent-pending micro-adjustable flip stop that is designed to work within the miter gauge slot of our Combo Track. StealthStops glide up and down the track effortlessly and lock firmly with a simple twist of a hex key. When folded down, the stop is completely contained within the slot. Flip it out and it locks square to the track and rigidly in place. The micro-adjuster thumbwheel allows you to fine tune the position of the stop with precise control.

Having a great stop doesn’t do you a lot of good if adapting it to your saw is so complicated it never gets done. That’s why we went further and designed three simple-to-install configurations. You can mount the track vertically, flush mount it horizontally or stack a vertical track on top of a horizontal track. The stacked option gives you something no other stop system can deliver…stops very close to each other.

Our specially designed brackets link the horizontal track to the vertical track at 90° to each other. Now you can have stops in both fences, letting you locate two stops within a fraction of an inch of each other.

If you don’t need stops close together, you can mount a single track vertically or embed it into the surface of your table. The vertical mount is the easiest and the most familiar – it looks like an ordinary back fence. The installation brackets slide into the back of the track and then screw down to your work surface. The bracket is also designed to be a convenient storage point for the provided 1/8" screwdriver-handled hex key.

For the horizontal flush mount, you can rout a 1/2" deep groove in your work surface. Or, for a simpler approach that doesn’t involve cutting your table, mount the track on top of the work surface and butt 1/2" plywood up to both sides of the track, creating the same flush surface.

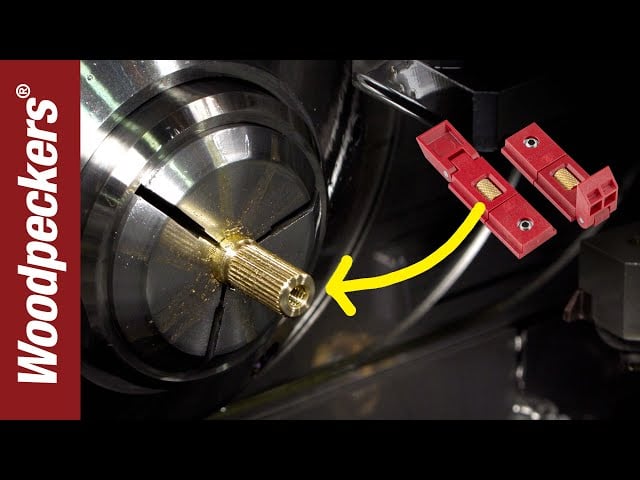

The main components of the StealthStop are injection-molded with glass-reinforced polycarbonate. All the internal components are either stainless or zinc-plated. The micro-adjust thumbwheel is turned from brass. It’s all low maintenance and rust resistant. We offer separate single-track kits for the right and left side of your saw (the tape reads from left-to-right or right-to-left). The same goes for the stacked track packages…there’s one for the right and one for the left. The single-track kits include one 4' track, five mounting brackets, two stops, a combination inch/metric tape, a 1/8" screwdriver-handled hex key and mounting hardware. The stacked track kits have all the same components plus a second 4' track and two more stops.

Like all Woodpeckers tools, the SteathStop is precisely built and carefully inspected in Strongsville, Ohio factory (just south of Cleveland).

Additional Info

- Creating consistent cuts in woodworking projects

- Enhancing precision in repeated cutting tasks

- Streamlining the process of making multiple cuts of the same length

- Improving safety by minimizing the need to measure and mark each cut manually

- Facilitating intricate woodworking designs that require accurate and repeatable cuts

- Increasing efficiency in woodworking shops by reducing setup time for cuts

- Allowing for quick adjustments between cuts without losing accuracy

- Enabling fine-tuning of cuts for perfect alignment and fit in joinery

- Supporting complex projects that involve cuts at various lengths but require consistency

- Optimizing the use of materials by ensuring precise cuts, reducing waste

- Enhancing the capability of a standard miter saw to perform like a more advanced cutting system

- Providing a solution for projects that require closely spaced cuts, impossible with traditional methods

- Adapting to different woodworking setups, whether for hobbyists or professional shops

- Allowing woodworkers to focus more on creativity and less on the technicalities of cutting

- Streamlining the production of custom furniture pieces that require precision cutting

-

-

Download Manual Instructions

Download Manual Instructions StealthStop Miter Saw Fence & Stop System | Woodpeckers Woodworking Tools

StealthStop Miter Saw Fence & Stop System | Woodpeckers Woodworking Tools Upgrade Your Miter Station With STEALTHSTOP | Deep Dive | Woodpeckers Tools

Upgrade Your Miter Station With STEALTHSTOP | Deep Dive | Woodpeckers Tools Making The StealthStop | Woodpeckers Tools | Production Update

Making The StealthStop | Woodpeckers Tools | Production Update