Avoid Tearout in Plywood: Pro Tips for Clean Cuts & Crisp Edges

Table of Contents

Plywood is strong and stable—but its thin face veneers and alternating grain make it prone to tearout. Use these proven techniques to get showroom-clean results with routers, saws, and CNC.

Why Plywood Tears Out—and How to Beat It

Plywood is an engineered panel built from thin veneers glued at alternating 90° grain directions. That cross-laminated structure is fantastic for stability and strength—but it also means a cutter is always working with the grain on one layer and against it on the next. Add paper-thin face veneers and tough glue lines, and you’ve got a material that chips the moment tooling or technique isn’t dialed in.

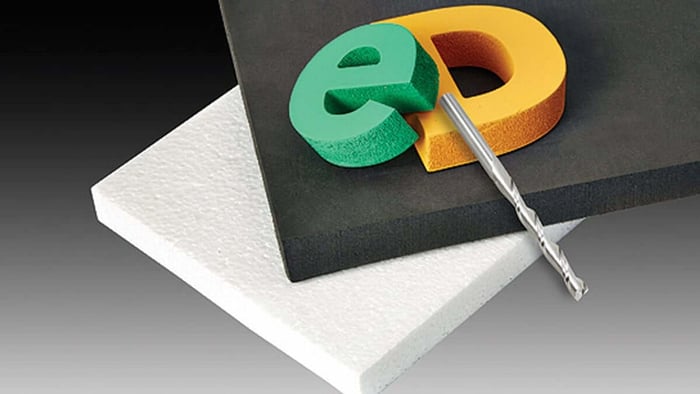

ToolsToday offers Baltic Birch Plywood in thicknesses from 1/8" to 3/4"

ToolsToday offers Baltic Birch Plywood in thicknesses from 1/8" to 3/4"What Exactly Is Plywood?

Plywood consists of 3–13+ plies of wood veneer bonded with adhesive. The grain of each ply is oriented perpendicular to its neighbors for strength and dimensional stability. Face veneers are cosmetic and thin; inner plies carry most of the structure and may vary in quality depending on grade.

Quick take:

- Pros: strong, stable, cost-effective, large panels

- Cons: thin face veneers, alternating grain, glue lines → tearout risk

Why Plywood Is Susceptible to Tearout

- Alternating grain: every pass hits end-grain on some layer, pushing fibers up and out.

- Paper-thin faces: tiny chips = ruined surface; there’s no material to sand away.

- Voids in cores: lower grades may have gaps that blow out the veneer above.

- Glue lines: resins abrade tooling quickly; dull cutters pry instead of slice.

- Unsupported exit: without backing, veneers splinter as the tool exits.

Tearout: Plywood vs. Solid Wood

| Factor | Solid Wood | Plywood |

|---|---|---|

| Grain direction | Mostly consistent (with occasional reversals near knots). | Alternates every layer—always some against-grain cutting. |

| Surface thickness | Full thickness; minor tearout can be planed/sanded. | Very thin face; even small chips expose core. |

| Internal structure | Relatively uniform. | Glue lines, possible voids, mixed plies. |

| Tool wear | Dulls slower. | Adhesives dull tools faster → more chip risk. |

| Entry/exit edges | Splintering mainly on exit edge. | Both entry and exit edges vulnerable. |

Amana Tool 46415 Solid Carbide Spiral Plunge 1/4" D x 1" Cutting Height x 1/4" Shank x 2.5" Long 2-Flute Down-Cut Router Bits are ideal for plywood.

Amana Tool 46415 Solid Carbide Spiral Plunge 1/4" D x 1" Cutting Height x 1/4" Shank x 2.5" Long 2-Flute Down-Cut Router Bits are ideal for plywood.How to Avoid Tearout in Plywood

1) Choose the Right Cutter

- Routing (handheld/trim table/CNC):Use spiral geometry & solid carbide.

- Down-cut spiral: presses top veneer down → clean top face; mind chip evacuation.

- Up-cut spiral: best chip clearing and clean bottom face; top face can fuzz.

- Compression spiral: up-shear at the tip + down-shear above → clean both faces; ideal for sheet goods.

- Table/track/circular saw: High-tooth-count, carbide-tipped plywood blade (e.g., 60–80T on 10").

- Jigsaw: get one designed for plywood to protect the top veneer.

Tooling note:

Quality carbide and proper grind matter. Compression spirals with optimized up/down flute lengths are the gold standard for plywood, especially on CNC.

2) CNC-Specific Tips

- Bit choice: Compression spiral, sized so the neutral point sits within the sheet thickness at full depth.

- Stepdown: Use multiple shallow passes; finish with a 0.3–0.5 mm full-depth contour cleanup.

- Hold-down: Vacuum, tabs, or onion-skin (leave ~0.3 mm) to prevent panel chatter and edge blowout.

- Toolpaths: Conventional rough, climb finish often yields the crispest edge on veneers.

- Dust extraction: Keep the kerf clean so chips don’t recut and pry the veneer.

These Spektra bits are designed for plywood. Little known secret: Spektra bits work in table routers, too - and a coated bit will always cut cleaner, for longer, than an uncoated bit.

These Spektra bits are designed for plywood. Little known secret: Spektra bits work in table routers, too - and a coated bit will always cut cleaner, for longer, than an uncoated bit. 3) Keep Tools Razor Sharp

- Glue lines abrade edges—rotate, hone, or replace bits and blades more often than you would for solid wood.

- Listen/feel for tearout: more noise or push force often signals a dull edge.

4) Support the Fibers

- Zero-clearance inserts on table/miter saws eliminate gaps around the blade.

- Sacrificial backers behind the cut (router, drill press, jigsaw) prevent exit-edge splintering.

- Painter’s tape over the cut line helps hold veneer fibers together.

- Score the line with a sharp knife before cutting to pre-sever face fibers.

5) Dial In Feed, Speed & Pass Strategy

- Light finishing pass: Leave ~0.3–0.5 mm (0.012–0.020") for a final clean-up climb pass.

- Avoid forcing the cut: Too fast = chipping; too slow = heat/burn & early dulling.

- Climb cut (with care): A very shallow climb pass can reduce lifting on veneers; use with firm workholding and proper stance.

6) Orient for the Clean Face

- Table/track saw: Best face up (teeth cut downward through the face).

- Handheld circular saw: Best face down (teeth exit upward on the top surface).

- Router: Match bit to face—down-cut protects top; up-cut protects bottom; compression protects both.

Common mistake:

Trying to “fix” tearout by sanding through a face veneer. Don’t. You’ll expose the core and make finishing harder. Prevent it at the tool instead.

Quick Checklist: Gear That Reduces Tearout

- Compression, down-cut, and up-cut spiral router bits (carbide).

- High-tooth-count plywood/crosscut saw blade with a zero-clearance insert.

- Painters tape, sharp utility knife, quality backer boards.

- Good dust extraction to keep the cut clean and cool.

Bottom Line

Plywood wants to chip because of its construction—but with sharp spiral tooling, proper support, and smart feeds and passes, you can deliver factory-clean edges on both faces. Set up once, and tearout stops being a gamble and starts being rare.

FAQs

What router bit is best for plywood?

A compression spiral is the top choice because it shears down on the top veneer and up on the bottom, leaving both faces clean.

Why does my plywood still chip with a fine-tooth blade?

If your insert isn’t zero-clearance, fibers can still break away. Add a zero-clearance insert, use painter’s tape, and score the cut line.

Down-cut or up-cut spiral—when should I use each?

Down-cut protects the top face (great for handheld routing). Up-cut clears chips and protects the underside. Compression covers both faces, especially on CNC.

Can I sand out tearout on veneer plywood?

Not safely. Face veneers are thin; sanding through exposes the core. Prevent tearout at the machine with sharp tooling and proper support.

Does cutting direction matter on a table saw vs. circular saw?

Yes. Put the best face up on a table/track saw; best face down with a handheld circular saw due to tooth direction.