CNC Router Bits vs Regular Bits: Why It Matters for Projects

How CNC Router Bits Differ from Regular Router Bits<span class="fr-marker" data-id="0" data-type="true" style="display: none; line-height: 0;"></span><span class="fr-marker" data-id="0" data-type="false" style="display: none; line-height: 0;"></span>

What are CNC Router Bits?

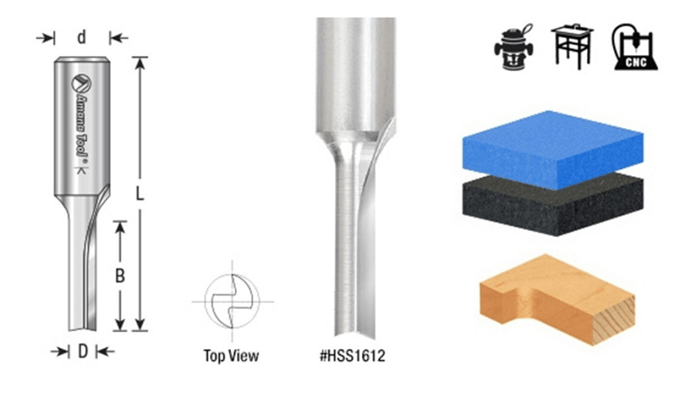

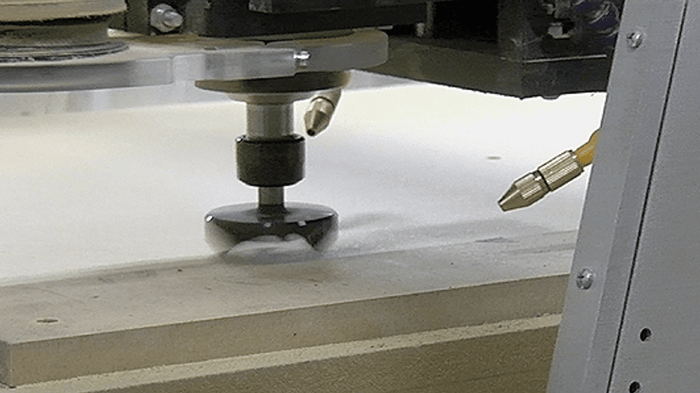

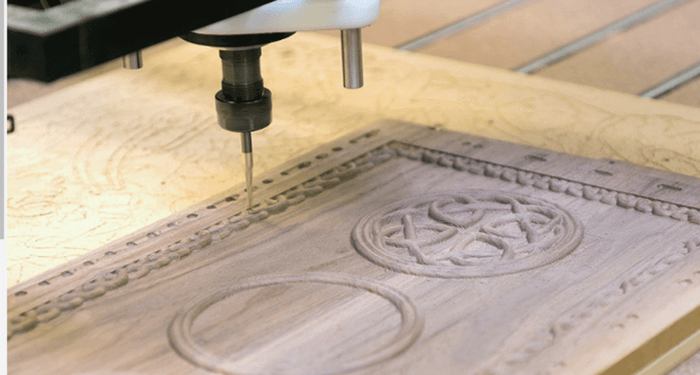

CNC router bits are precision tools designed for use with CNC machines. These tools are optimized for cutting materials such as wood, metal, and plastics at high speeds with exceptional accuracy, which is crucial for automated processes. Regular bits, on the other hand, are not built to handle such high precision and speed.

Differences Between CNC Router Bits and Regular Router Bits

The key difference between CNC router bits and regular bits lies in their design. CNC bits are engineered for high-speed, precise cutting, making them ideal for CNC machines. Regular bits are not designed to handle the demands of CNC operations, which leads to less accurate cuts and faster wear.

Materials and Construction

The construction of CNC bits often involves materials like high-speed steel (HSS) or carbide. These materials ensure that the bits can perform effectively on a range of workpieces, including harder materials like metal and dense woods. Regular bits are often made from lower-grade materials and are not designed for the high speeds and precision needed in CNC operations.

Performance and Precision

CNC bits are designed to maintain high cutting speeds and sharpness for long periods. With proper maintenance, these bits can consistently produce high-quality results. In contrast, regular bits may dull quickly or become less effective when used in CNC machines, leading to inefficient and inaccurate results.

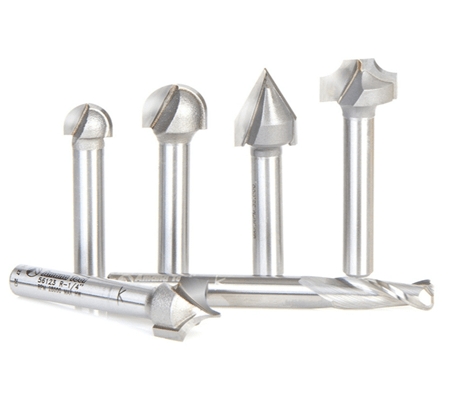

Amana Tool AMS-223 6-Pc CNC Lettering Router Bit Set, 1/4 Inch Shank For the most demanding signmaking lettering and engraving tasks. Designed for creating signs and other CNC projects in a variety of materials.

Amana Tool AMS-223 6-Pc CNC Lettering Router Bit Set, 1/4 Inch Shank For the most demanding signmaking lettering and engraving tasks. Designed for creating signs and other CNC projects in a variety of materials.Why Regular Router Bits Shouldn't Be Used in CNC Machines

Using regular bits in a CNC machine can lead to a number of issues, including poor quality cuts, increased wear on the tools, and potential damage to both the machine and the workpiece. CNC bits are specifically designed to handle the high-speed, automated operations of CNC machines.

Potential Damage to Machine and Workpiece

Regular bits are not built for the high-speed rotation and precision required in CNC machining. Using these tools can result in excess vibration, overheating, and inaccuracies that damage both the workpiece and the machine itself. For instance, using a regular bit on a harder material like metal can cause the bit to wear down prematurely, resulting in poor-quality cuts.

Inefficiency and Inaccuracy

When you use regular bits in CNC machines, you risk encountering inefficiencies and inaccuracies in your work. CNC bits are designed to ensure precision in automated settings, allowing for faster and more accurate cuts. Regular bits, however, may not produce the same level of detail and may slow down production.

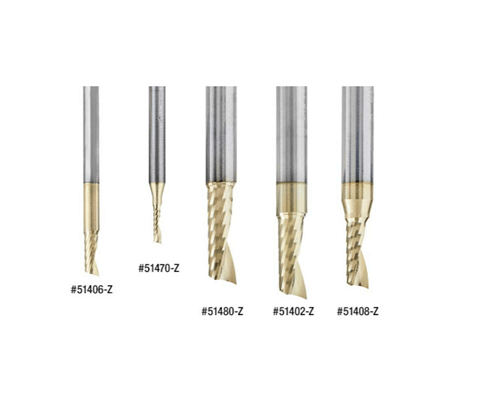

Amana Tool 51373-Z-5, 5-Pack CNC SC Spiral O Single FluteAluminum Cutting 1/8 D x 5/16 CH x 1/4 SHK x 1-1/2 Inch Long Up-Cut ZrN Coated Router Bits with Mirror Finish.

Amana Tool 51373-Z-5, 5-Pack CNC SC Spiral O Single FluteAluminum Cutting 1/8 D x 5/16 CH x 1/4 SHK x 1-1/2 Inch Long Up-Cut ZrN Coated Router Bits with Mirror Finish.Choosing the Right CNC Bits for Your Project

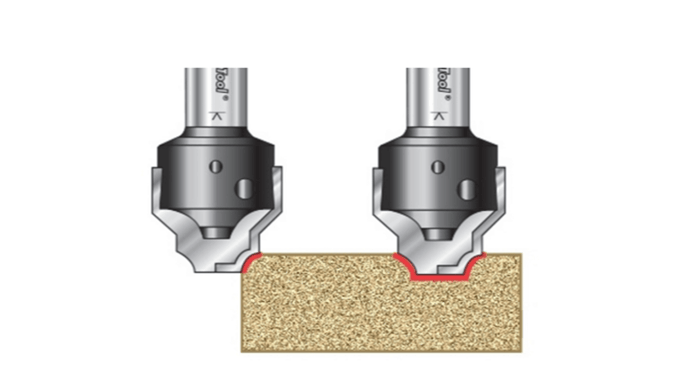

Choosing the right CNC bits for your project is essential to achieving high-quality results. Factors like material type, cutting geometry, and application should all be considered to ensure that you are using the correct tool for the job.

Factors to Consider

When selecting CNC bits, take into account the type of material you're working with, as well as the desired cut type and finish. For example, spiral bits are great for clean cuts on wood, while straight bits are ideal for heavy-duty cuts. Understanding the material properties and cutting needs will help you choose the right tools for your project.

Types of CNC Bits

There are many types of CNC bits, each suited to different tasks:

- Spiral bits are ideal for smooth finishes and efficient chip removal.

- Straight bits are used for heavy-duty cutting, like sign-making.

- Up-cut bits lift chips away from the workpiece, preventing burn marks.

- Down-cut bits push chips downward, providing a clean edge on the top surface.

- Compression bits combine up-cut and down-cut designs for a clean finish on both sides of laminated materials.

Proper Maintenance and Care for CNC Bits

Maintaining CNC bits is essential for ensuring long-lasting performance. Regular inspections, cleaning, and proper storage can extend the life of your tools and ensure optimal cutting efficiency.

Tips for Prolonging Lifespan

To extend the life of CNC bits, focus on proper chip removal during cutting, avoid excessive heat buildup, and inspect the tools regularly for wear. These practices can help maintain the sharpness of your bits and prevent premature wear.

Solid Carbide CNC 118 Degree Point Spade Drills / Router Bits for Steel, Stainless Steel & Non-Ferrous Materials.

Solid Carbide CNC 118 Degree Point Spade Drills / Router Bits for Steel, Stainless Steel & Non-Ferrous Materials.Frequently Asked Questions

What is the difference between CNC bits and regular bits?

CNC bits are specifically designed for high-speed, precise cuts in CNC machines, while regular bits are intended for handheld or stationary routers.

Can I use regular router bits in a CNC machine?

While it’s technically possible, it’s not recommended. Regular bits are not built to handle the high speeds or precision of CNC operations, which can lead to poor-quality results and possible damage to the machine.

What are the key features of CNC bits?

CNC bits are typically designed with more flutes, a stronger shank, and coatings that withstand the high speeds and temperatures of CNC machines.

Are CNC bits more expensive than regular bits?

Yes, they tend to be more expensive, but they offer better durability and performance, making them more cost-effective over time.