Engraving Bits Compared: Dremel® vs. Amana Tool®

Table of Contents

When people search for “dremel engraving bits” they’re often at the entry point: rotary tools, hobby engraving, and small craft jobs. But when precision, repeatability, and production throughput matter, Amana Tool’s engraving tooling (including its In-Groove insert system) is the pro-grade step up. This guide compares Dremel engraving bits, Amana solid-carbide engraving bits, and the Amana In-Groove system so you can pick the right tool for your work.

Dremel Engraving Bits: Hobby-Friendly

Dremel engraving bits are designed for handheld rotary tools (Dremel 3000, 4000 and similar). They’re inexpensive, easy to use, and widely available — ideal for personalizing gifts, etching designs into small pieces, and light craft work.

Typical characteristics

- Shank: mostly 1/8" (fits common rotary tool collets)

- Materials: high-speed steel, carbide, and diamond-coated tips for very hard surfaces

- Shapes: ball/round, cone, cylinder, diamond point

- Best for: soft woods, plastics, jewelry, leather, occasional glass or ceramic etching (diamond bits)

Benefits

- Low cost and widely available in multipacks

- Good for quick freehand detail and hobby projects

- Easy to change — no special equipment required

Limitations

- Shorter edge life when used on harder materials or in high-use scenarios

- Limited profile variety compared to professional CNC tooling

- Shallow cut capacity and not built for production CNC routers

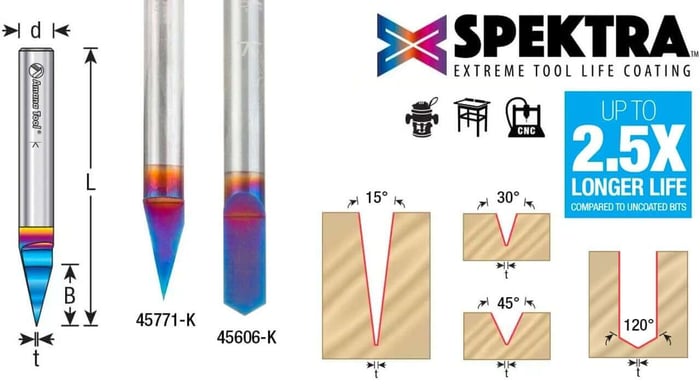

15°, 30°, 45° and 120° Solid Carbide Spektra Extreme Engraving Bits for Signmaking Amana Tool® solid carbide router bits provide consistent, repeatable quality. Every tool is guaranteed to match the geometry on the prints, every time on every order.

15°, 30°, 45° and 120° Solid Carbide Spektra Extreme Engraving Bits for Signmaking Amana Tool® solid carbide router bits provide consistent, repeatable quality. Every tool is guaranteed to match the geometry on the prints, every time on every order. Amana Tool — solid-carbide engraving bits (professional grade)

Amana Tool engraving bits are manufactured to CNC shop standards: precision-ground carbide, tight tolerances, and geometries optimized for clean cuts and efficient chip evacuation. These bits are designed for routers and CNC spindles rather than handheld rotary tools.

Typical characteristics

- Shanks: available in 1/8", 1/4", and 1/2" (fits routers and CNC collets)

- Materials: solid carbide or carbide-tipped geometries

- Shapes: V-bits (30°, 45°, 60°, 90°), fine-point engraving, tapered ballnose, core box, corner rounds, etc.

- Best for: hardwoods, MDF, HDU sign foam, plastics, laminates, and non-ferrous metals

Benefits

- Longer edge life and consistent cuts across long runs

- Wide range of cutting profiles for lettering, detailed carving, and signmaking

- Engineered for repeatable CNC results — less cleanup and better finish

Limitations

- Each cutting profile is a dedicated bit — if you need many profiles you'll buy many bits

- When the flutes or tip dull, the entire bit needs replacement or professional sharpening

In-Groove CNC Insert Engraving Tools The Most Versatile System for Signmaking, Lettering & Engraving!

In-Groove CNC Insert Engraving Tools The Most Versatile System for Signmaking, Lettering & Engraving! Amana In-Groove Insert Engraving System — the production advantage

For shops that engrave daily — sign shops, panel engraving, part-number marking or any application where spindle time is billable — Amana’s In-Groove Insert System is designed to reduce downtime, increase flexibility, and lower lifetime tooling cost.

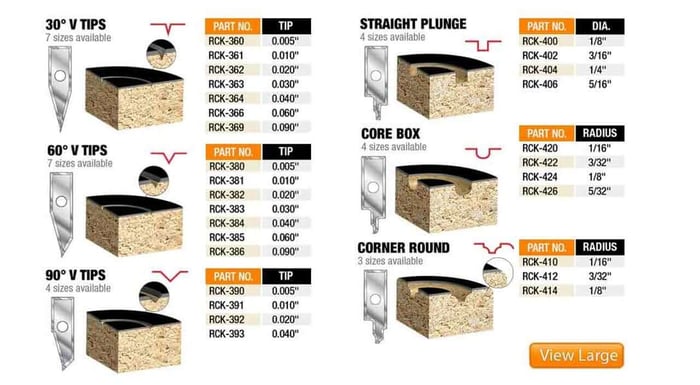

How it works

A single tool body accepts small, precision insert knives. Instead of buying a separate solid-carbide bit for each profile, you keep one (or a few) bodies and change the tiny insert to get a new profile: V-tips, corner rounds, core boxes, ball nose, straight engraving, and more.

Key advantages

- Profiles on demand: one body supports ≈30 interchangeable insert shapes.

- Faster changeovers: many shops can swap inserts in-machine without removing the tool from the spindle.

- Lower consumable cost: replace a small carbide insert instead of the entire bit.

- Longer edge life: industrial-grade inserts are optimized for durability and clean edges.

- Less waste: only the insert is discarded, not the entire tool.

Quick comparison table

| Feature | Dremel Engraving Bits | Amana Solid-Carbide Bits | Amana In-Groove Insert System |

|---|---|---|---|

| Target user | Hobbyists, DIYers | CNC woodworkers, sign shops | Production shops, signmakers, high-throughput CNC |

| Tool type | Rotary tool accessories | CNC router bits | CNC insert tooling system (tool body + inserts) |

| Durability | Short edge life on hard or abrasive materials | Long edge life; reliable for production | Longest life overall — replace only the insert |

| Profiles per tool | One profile per bit | One profile per bit | One body supports ~30 different insert profiles |

| Changeover speed | Quick bit swap (hand tool) | Requires tool change / collet swap | Insert swap in spindle; minimal downtime |

| Cost structure | Low upfront; disposable | Mid to high per bit; replace or sharpen | Higher initial buy-in for bodies; low ongoing cost for inserts |

Which should you choose?

Start with Dremel bits if you are experimenting with engraving, doing occasional freehand work, or simply want a low-cost way to learn technique.

Choose Amana solid-carbide bits when you move to router-based engraving, require clean, repeatable cuts, or work across a wide range of materials and need the improved edge life and geometry options that professional work demands.

Upgrade to the Amana In-Groove system when spindle time is valuable: sign shops, production CNC operations, and any shop where fast changeovers, many profiles, and predictable tooling costs matter. The In-Groove system converts profile flexibility into real labor and consumable savings.

FAQs

What’s the difference between engraving and etching?

Engraving removes material with a cutting tool or bit, creating grooves or recesses in the surface. Etching usually refers to using chemicals, lasers, or abrasives to mark a surface without cutting as deeply. Engraving with CNC or rotary tools is more durable and precise for signage, woodworking, and metal marking.

Can Dremel engraving bits cut metal?

Yes, Dremel engraving bits can mark soft metals like aluminum, brass, or copper. However, they aren’t designed for deep cuts or industrial use. For long-lasting results on harder metals, CNC users typically turn to solid-carbide or insert-based engraving bits.

What engraving bits work best for glass?

Dremel diamond-tipped engraving bits are a popular choice for hobby glass etching and detailing. For CNC routers, specialized diamond drag engraving bits or fine-point carbide bits provide cleaner results and greater consistency on glass, acrylic, or crystal.

Which engraving bit is best for CNC signmaking?

Amana Tool solid-carbide V-tip and In-Groove insert engraving bits are widely used by professional signmakers. They allow for crisp lettering in wood, HDU, plastics, and even aluminum, with longer tool life than hobby-grade bits.

How do I choose the right engraving bit for my project?

Consider your material (wood, plastic, metal, or glass), your tool (rotary tool vs. CNC router), and the desired detail level. Hobbyists often start with Dremel engraving sets, while professionals choose Amana Tool carbide or In-Groove insert systems for durability and flexibility.