Material Sourcing & Cost Control for Small Manufacturing Shops

Table of Contents

- Why Material Costs Hit Small Shops Harder

- Build a Short, Trusted Supplier List

- Standardize Materials Wherever Possible

- Track Yield, Not Just Price

- Buy Smarter, Not Bigger

- Design for Material Efficiency

- Use Scrap Intentionally

- Audit Your Material Process Quarterly

- Final Thoughts

- Printable: One-Page Material Audit Checklist

- FAQs

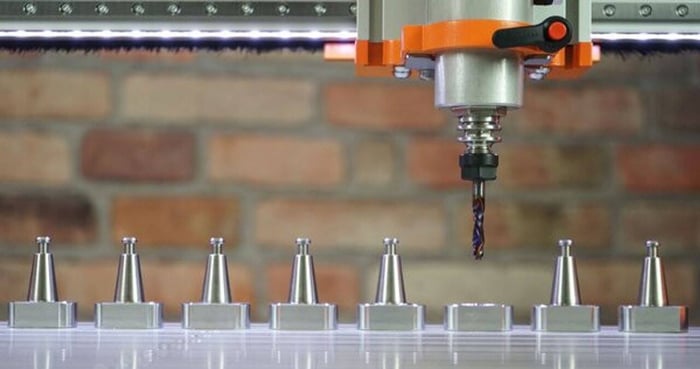

Small manufacturing shops live and die by margins. You can dial in feeds and speeds, optimize toolpaths, and squeeze every minute out of your machines—but if your material costs aren’t under control, profit still slips through the cracks.

Material sourcing isn’t just about finding the cheapest supplier. It’s about consistency, predictability, waste reduction, and smart buying decisions that support your production flow. Whether you’re running a CNC router, small mill, laser, or hybrid shop, better material discipline can quietly become one of your biggest competitive advantages.

Why Material Costs Hit Small Shops Harder

Large manufacturers can absorb material price swings with volume discounts and long-term contracts. Small shops don’t have that luxury. A single bad buy—warped plywood, inconsistent aluminum stock, mislabeled plastics—can increase scrap rates, slow setups and machining, and force rework or remakes.

The goal isn’t perfection. It’s control.

Large Baltic birch plywood panels for laser cutting, engraving, CNC and DIY projects. From 1/8" to 3/4" thick and from 12"x12" to 24"x48" or 36"x36".

Large Baltic birch plywood panels for laser cutting, engraving, CNC and DIY projects. From 1/8" to 3/4" thick and from 12"x12" to 24"x48" or 36"x36".Build a Short, Trusted Supplier List

Instead of chasing new vendors for every job, focus on building 2–3 reliable suppliers per material type. Look for vendors who offer consistent grades and tolerances, clear labeling and documentation, reliable lead times, and are willing to answer technical questions.

Pay attention to how material arrives. Poor packaging often leads to hidden damage that only shows up once machining starts.

Standardize Materials Wherever Possible

Custom materials kill margins faster than most shops realize. If you can standardize sheet sizes, thicknesses, and a small set of go-to grades (alloys, plastics, wood goods), you gain predictable feeds and speeds, repeatable fixturing, fewer tool changes, and easier inventory tracking.

Even small changes—like limiting acrylic thicknesses or using one aluminum alloy for most jobs—can simplify your entire workflow.

Track Yield, Not Just Price

The cheapest sheet isn’t always the cheapest part. Two suppliers might offer the same nominal material, but one warps under clamping, one machines cleaner, and one produces better edge quality.

Track yield per sheet, not just cost per unit. If one material produces 10% less scrap, it’s often worth paying more upfront.

A simple spreadsheet can reveal patterns quickly. Track:

- Supplier

- Material and thickness/grade

- Price and date

- Scrap rate (estimated is fine)

- Machining notes (warp, tearout, edge finish, etc.)

Buy Smarter, Not Bigger

Bulk buying can help—but only if it aligns with your workflow. Before buying larger quantities, ask:

- Do I use this material every month?

- Does it store safely in my shop?

- Will it degrade, warp, oxidize, or absorb moisture?

Dead inventory ties up cash and floor space. A slightly higher per-sheet cost with steady turnover is often healthier than a “deal” that sits unused for six months.

Design for Material Efficiency

Cost control doesn’t start at purchasing—it starts at design. Encourage:

- Efficient nesting and consistent part orientation

- Avoiding unnecessary thickness

- Designing to standard sheet sizes and common stock dimensions

- Reusing common blanks across jobs

Good CAM strategies can reduce waste dramatically without adding machine time.

Use Scrap Intentionally

Scrap happens—but unmanaged scrap is wasted opportunity. Many shops save offcuts for fixtures, use smaller remnants for test cuts, and label usable scrap by size and material.

If you can, designate a “usable scrap” rack so good material doesn’t get thrown out—or forgotten.

Audit Your Material Process Quarterly

At least once every few months, step back and ask:

- Which materials are eating margin?

- Which suppliers cause the most problems?

- Where does scrap really come from—design, setup, machining, or handling?

These audits don’t need to be formal. A one-hour review can uncover issues that quietly drain profit all year.

Final Thoughts

Material sourcing and cost control aren’t glamorous—but they’re foundational. Shops that treat material as a strategic input, not just a commodity, earn more predictable jobs, cleaner production runs, better quoting accuracy, and stronger margins without raising prices.

In a competitive manufacturing landscape, quiet efficiency often wins.

Printable: One-Page Material Audit Checklist

How to use: Print this section and complete it quarterly or whenever material costs start creeping up.

1. Material Inventory Snapshot

- ☐ Primary materials currently stocked:

- ☐ Approximate quantities on hand:

- ☐ Average time material sits before use:

Aluminum (alloy / thickness): _______________________________

Plywood / MDF: _____________________________________________

Plastics (type / thickness): _________________________________

Other: _____________________________________________________

Inventory status:

☐ Overstocked ☐ Understocked ☐ Just right

2. Supplier Reliability Check

For primary materials, check all that apply:

- ☐ Consistent quality

- ☐ Accurate labeling

- ☐ On-time delivery

- ☐ Proper packaging

- ☐ Responsive communication

Problem supplier(s): _______________________________________

Notes: ____________________________________________________

3. Scrap & Waste Reality Check

Scrap rate feels:

☐ Acceptable ☐ Too high ☐ Unknown

Primary scrap causes (check all that apply):

- ☐ Warping / flatness issues

- ☐ Thickness inconsistency

- ☐ Poor edge quality

- ☐ Setup errors

- ☐ Design inefficiency

- ☐ Tool wear

- ☐ Handling or storage damage

4. Yield vs. Price Check

☐ Cheapest material performs best

☐ Mid-priced material performs best

☐ Premium material saves time and reduces scrap

Best-performing material: _________________________________

Material causing issues: _________________________________

5. Design & CAM Alignment

- ☐ Parts nest efficiently

- ☐ Designs use standard stock sizes

- ☐ Thicknesses are justified

- ☐ CAM strategies minimize waste

- ☐ Fixtures use scrap where possible

One design or CAM change to test next cycle:

___________________________________________________________

6. Scrap Reuse & Storage

- ☐ Usable scrap is labeled

- ☐ Scrap is sorted by material

- ☐ Scrap is reused regularly

- ☐ Scrap storage is organized

Immediate improvement to make:

___________________________________________________________

7. Action Items

Top 3 fixes to test:

1. _______________________________________________________

2. _______________________________________________________

3. _______________________________________________________

Material or supplier to reevaluate: ________________________

Next audit date: _________________________________________

Tip: Bookmark this page and reprint this checklist every quarter.

FAQs

How can small manufacturing shops reduce material costs without buying cheaper stock?

Small shops often reduce material costs by improving consistency rather than chasing lower prices. Standardizing materials, choosing reliable suppliers, improving part nesting, and reducing scrap typically saves more money than switching to the cheapest available stock.

What causes the most material waste in small shops?

The most common causes are warped or inconsistent material, poor nesting or design choices, setup errors, dull tooling, and improper storage. In many shops, waste comes from multiple small issues rather than a single obvious mistake.

Is it better to buy materials in bulk or as needed?

It depends on usage patterns and storage conditions. Materials used consistently and stored properly can benefit from bulk purchasing. Infrequently used materials often tie up cash and floor space, making smaller, more frequent purchases the better option.

How do I know if a material supplier is costing my shop money?

Warning signs include inconsistent thickness, unexpected warping, poor edge quality, frequent rework, and unclear labeling. If a material slows setups or increases scrap, it may be more expensive overall—even if the purchase price is lower.

Why is tracking yield more important than tracking material price?

Yield reflects how much usable product you get from each sheet or bar. A higher-priced material that machines cleanly and produces less scrap often results in a lower cost per finished part than cheaper material with poor consistency.

How can design choices affect material costs?

Design decisions such as unnecessary thickness, non-standard stock sizes, or inefficient part layouts increase waste. Designing parts around standard material dimensions and nesting them efficiently helps reduce scrap and improve overall cost control.

Should small shops keep and reuse scrap material?

Yes, when managed intentionally. Clearly labeled and organized scrap can be reused for fixtures, test cuts, and small parts. Unsorted or forgotten scrap, however, often becomes wasted material instead of a cost-saving resource.