Workflow Layout for Small-Batch Production

Table of Contents

- How Small Shops Can Run Faster, Smarter, and More Profitably

- 1. Start With a Linear, Forward-Moving Workflow

- 2. Create a CNC-First Production Core

- 3. Standardize Tooling for Faster Changeovers

- 4. Segment Your Shop Into Functional Micro-Zones

- 5. Adopt Lean Manufacturing Principles (Sized for Small Shops)

- Make your own cart with Matt's downloadable & customizable Utility Cart CNC Plans

- 6. Use Carts to Move Work Instead of People

- Final Thoughts: Build a Shop That Works With You, Not Against You

- FAQs

How Small Shops Can Run Faster, Smarter, and More Profitably

Small professional shops face a unique challenge: every job is different, batch sizes are tiny, and production must stay profitable despite frequent changeovers. A well-designed workflow layout for small-batch production can dramatically improve efficiency, reduce mistakes, and keep turnaround times predictable — even when customers want everything “by tomorrow.”

Whether your shop runs CNC routers, CNC mills, or a hybrid of manual and automated equipment, the right workflow keeps your team moving smoothly from raw stock to finished parts. Below is a practical, CNC-focused guide to designing a layout that supports small-batch flexibility without sacrificing speed.

1. Start With a Linear, Forward-Moving Workflow

The core principle of an efficient workshop layout is unidirectional flow. Material should move forward — never backtrack — from:

- Material Receiving & Storage

- Rough Cutting / Breaking Down Stock

- CNC Machining

- Finishing / Secondary Operations

- Quality Control

- Packing & Shipping

This reduces travel time, improves job tracking, and minimizes pileups in high-traffic areas. In small-batch environments, where changeovers happen constantly, linear flow prevents chaos.

Shop Tip:

Position your CNC machines so operators can move quickly between stations. For example, placing a CNC router near rough-cut saws reduces the number of times large sheets or blanks need to be handled.

2. Create a CNC-First Production Core

In small shops today, CNC equipment drives the majority of precision work. Your workflow layout should reflect that.

Why the CNC Zone Matters

- It’s the most consistent bottleneck.

- It dictates tool selection and job scheduling.

- It determines how quickly setups can change over.

Place CNC machines in an area with:

- Clear feed and outfeed zones

- Tool staging nearby

- Dust collection optimized for high throughput

- Room for carts or racks loaded with upcoming jobs

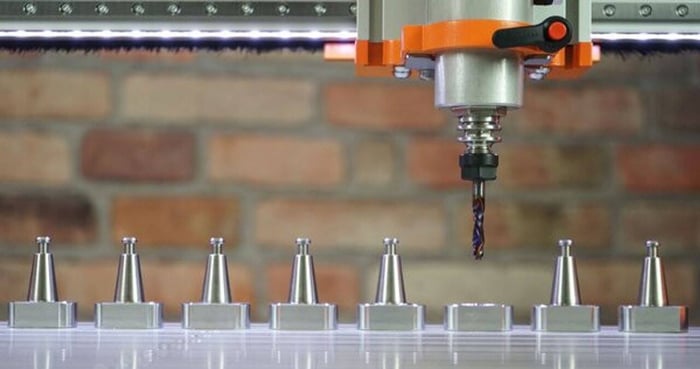

Tool Staging: The Hidden Efficiency Multiplier

One of the fastest ways to speed up small-batch work is to keep CNC tooling organized by job type, not by drawer.

Create a CNC tooling station near your machines stocked with:

- Job-ready router bit sets

- Downcut / upcut spiral bits

- Compression bits for plywood

- Aluminum-cutting end mills

- Spoilboards, clamps, and hold-downs prepared in advance

When operators don’t have to search for tooling, you cut setup times dramatically.

3. Standardize Tooling for Faster Changeovers

Small-batch production lives or dies on setup efficiency. Standardizing your cutting tools can save hours per week.

Use Consistent Tool Diameters and Profiles

Where possible:

- Use the same diameter end mills for pockets and profiles.

- Choose multi-purpose compression bits for varied sheet goods.

- Keep a consistent “tooling library” in your CAM software.

This allows operators to reuse program templates, reduce toolpath editing, and maintain predictable feed and speed settings.

CNC Bit Essentials for Small Shops

High-frequency tools worth standardizing include:

- 1/4" and 1/8" solid carbide spiral bits (wood, plastics, composites)

- Compression bits for clean top/bottom edges

- O-flute bits for acrylic and aluminum

- V-bits for engraving and chamfering

- Surfacing bits for tramming spoilboards

Amana Tool router bits like solid carbide spirals or premium compression bits work especially well here because they hold tolerances across a wide range of materials and batch sizes.

4. Segment Your Shop Into Functional Micro-Zones

Even in a small footprint, dividing your shop into purpose-built areas helps operators stay organized.

Recommended Zones

A. Material Prep Zone

- Panel saw or bandsaw

- Chop saw

- Labeling station

- Space for staging incoming stock

B. CNC Production Zone

- CNC router or mill

- Tooling cart

- Workholding station

- Dust collection

- Prep table for loading/unloading

C. Secondary Operations Zone

Includes whatever your shop uses:

- Edge banding

- Drilling

- Sanding

- Assembly

D. Quality Control Zone

Even a tiny QC table with calipers, fixtures, and gauge blocks avoids mistakes that bounce back into production.

E. Packing & Fulfillment Zone

A designated packing station prevents parts from getting lost or damaged when multiple jobs run at once.

5. Adopt Lean Manufacturing Principles (Sized for Small Shops)

You don’t need giant-factory “Lean” to get the benefits. A handful of principles work exceptionally well in small-batch CNC environments:

5S Organization

Sort, Set in order, Shine, Standardize, Sustain.

CNC bits, clamps, wrenches, and collets should all have homes.

Single-Minute Exchange of Dies (SMED)

The Lean method that reduces setup times.

In practice, this means:

- Prepare tooling while the machine is running

- Use quick-change workholding

- Keep duplicate “high-use” bits ready to go

Visual Workflow Tracking

A whiteboard or digital board listing:

- Job number

- Material type

- Tooling required

- Stage (Prep → CNC → QC → Pack)

This keeps small teams aligned at a glance.

Make your own cart with Matt's downloadable & customizable Utility Cart CNC Plans

Make your own cart with Matt's downloadable & customizable Utility Cart CNC Plans

Make your own cart with Matt's downloadable & customizable Utility Cart CNC Plans

Make your own cart with Matt's downloadable & customizable Utility Cart CNC Plans6. Use Carts to Move Work Instead of People

In small-batch production, jobs move constantly — so make the work mobile. Use rolling carts or racks to:

- Carry prep-cut blanks to CNC stations

- Hold tooling organized by job

- Stage work waiting for finishing

- Move completed batches to packing

This minimizes operator movement and keeps traffic lanes clear.

Final Thoughts: Build a Shop That Works With You, Not Against You

Small-batch production demands agility, precision, and fast changeovers — and your shop layout plays a huge role in all three. With a unidirectional workflow, a CNC-centric production core, standardized tooling, and lean micro-zones, even a small shop can run like a well-tuned manufacturer.

ToolsToday customers consistently find that investing in high-quality CNC bits and organizing tooling stations around their most-used cutters delivers some of the biggest efficiency gains of all.

FAQs

What is the best workflow layout for small-batch production?

The best workflow layout for small-batch production is a linear, forward-moving design where material flows from receiving to CNC machining to finishing without backtracking. This layout minimizes handling time, reduces clutter, and helps operators manage frequent changeovers more efficiently.

How can CNC machines improve a small shop’s workflow?

CNC machines centralize precision work and provide consistent repeatability, making them the core of an efficient workflow. By placing CNC equipment in a dedicated production zone with nearby tooling, prep tables, and dust collection, shops reduce setup time and keep jobs moving smoothly.

What tools should be kept near the CNC station?

Keep high-use CNC router bits, collets, wrenches, clamps, spoilboards, and job-specific tooling within arm’s reach of the CNC machine. Common essentials include spiral bits, compression bits, O-flute bits, V-bits, and surfacing bits—ideally organized on a dedicated tooling cart or wall rack.

How does standardizing CNC tooling help with small-batch production?

Standardizing tooling—such as using consistent bit diameters and preferred bit types—reduces the time spent reprogramming toolpaths and adjusting feeds and speeds. This makes changeovers faster and improves accuracy across different materials and job types.

How can small shops reduce downtime between jobs?

Shops can reduce downtime by preparing tooling while the CNC is running, using rolling carts to stage upcoming jobs, maintaining an organized tooling station, and implementing simple lean practices like 5S and visual job tracking. These steps make transitions smoother and increase total machine uptime.