Selecting the Right CNC Router for Low-Volume Manufacturing (and How to Get the Most from It)

Table of Contents

For small manufacturers, every minute and every cut counts. Whether you’re producing custom furniture, short-run signage, or prototype components, the right CNC router will transform your workflow — boosting precision, throughput, and consistency without adding headcount.

What “Low-Volume Manufacturing” Really Means

Low-volume manufacturing isn’t hobby-level tinkering — but it’s not a full-scale factory either. It’s that productive middle ground:

- Custom furniture and cabinetry runs in the dozens, not thousands

- Sign shops producing steady commercial orders

- Prototype or contract manufacturing of specialized parts

- Businesses that rely on repeatable precision, but value flexibility

For these operations, the ideal CNC router balances industrial durability with manageable footprint and cost — rugged enough for daily production, sized for a small or midsize shop.

Key Factors When Choosing a Production-Grade CNC Router

1) Table Size & Material Handling

A larger work area (e.g., 24"×36", 48"×96") increases efficiency for sheet goods and nested parts. If you’re cutting cabinet panels, full-size signage, or large components, table size determines not just what fits, but how many parts you process per setup.

2) Spindle Power & Duty Cycle

For production work, spindle horsepower and continuous-duty rating matter more than max travel speed. Higher-torque spindles handle dense hardwoods, plastics, and non-ferrous metals while maintaining consistent chip load and surface finish over long runs.

Look for routers designed for continuous use — they’ll hold tolerances longer and minimize unplanned downtime.

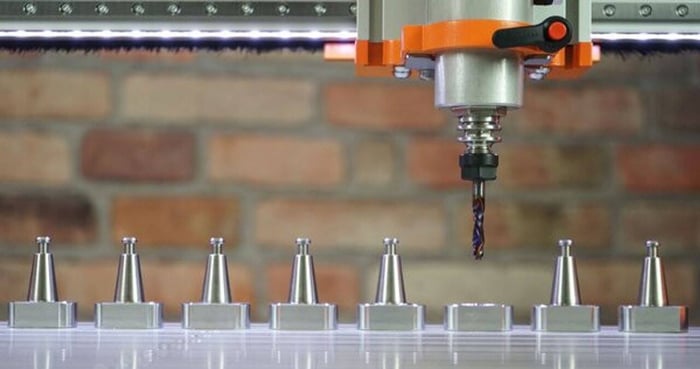

3) Tool Change & Workflow Efficiency

Automatic tool changers (ATC) save serious time when you run multiple operations. Even without full ATC, quick-swap collets or organized tool racks can keep throughput steady and setups consistent.

4) Software Compatibility & Integration

Repeatability is everything. Choose a router that plays nicely with common CAD/CAM platforms (e.g., Vectric VCarve, Aspire, Fusion 360) and supports reliable post-processors, nesting, and templated jobs for repeat runs.

5) Support, Training & Parts Availability

Production time is revenue. Machines backed by reliable support and parts availability — like those from Axiom, Next Wave, and STEPCRAFT (carried by ToolsToday) — keep your shop running when every hour counts.

CNC Routers for Low-Volume Production Available at ToolsToday

Axiom Precision CNC Routers (Pro+, Elite, AR Series)

Built for serious work in compact spaces, Axiom Precision machines deliver industrial-grade performance without an industrial footprint.

- Rigid steel frames reduce vibration and improve cut quality

- Optional vacuum table and 4th-axis for advanced workflows

- Continuous-duty spindles designed for sustained production

- Excellent pairings with Amana Tool Spektra® and insert-carbide bits

Best for: cabinet shops, furniture makers, and light production of composites or aluminum.

Next Wave Shark HD Series

The Shark HD lineup is ideal for smaller production runs, signage, and woodworking businesses needing consistent accuracy in a compact footprint.

- Rigid aluminum gantry with precision linear bearings

- Plug-and-play controller simplifies training for small teams

- Great choice for repeat signage and engraving workflows

Best for: signmakers, custom engravers, and short-run woodworking production.

STEPCRAFT D-Series (D.840 / D.600)

STEPCRAFT brings modular German engineering to small-scale production and prototyping in wood, plastics, and light metals.

- Modular design supports easy toolhead swaps

- Strong balance of precision, footprint, and affordability

- Excellent for labs and specialty parts manufacturing

Best for: prototyping labs, specialty components, and light manufacturing.

Tooling & Accessories That Multiply ROI

A CNC router is only as good as its tooling and setup. To maximize uptime and reduce cost per part, focus on:

- Router Bits: Choose Amana Tool Spektra® coated or insert-carbide bits for cool cutting and long tool life in production runs.

- Hold-Down Systems: Vacuum tables, T-slot clamps, and spoilboards keep parts secure and repeatable.

- Dust Collection: Effective extraction improves surface quality and operator safety. See dust collection solutions.

- Maintenance: Lubrication and inspection schedules protect spindle bearings and linear motion components.

Getting the Most Out of Your CNC Investment

For small manufacturers, success comes down to precision, uptime, and workflow efficiency. The right CNC router doesn’t just cut material — it cuts waste, setup time, and operator fatigue.

- Match table size to your production mix

- Choose spindle power and duty cycle for your hardest materials

- Adopt accessories that drive repeatability

- Rely on support that minimizes downtime

Ready to upgrade?

Explore our full line of production-ready CNC routers and Amana Tool bits engineered for continuous professional use.

FAQs

What is the best CNC router for small-scale manufacturing?

For small manufacturers, the best CNC router is one that balances industrial performance with a compact footprint. Machines like the Axiom Precision Pro+ or Next Wave Shark HD series are built for continuous-duty operation and precision, making them ideal for low-volume production without requiring factory-scale space or investment.

How much spindle power do I need for low-volume CNC production?

If you’re cutting hardwoods, plastics, or aluminum in a small manufacturing setup, aim for a spindle in the 2–3 HP range, with a continuous-duty rating. This ensures consistent torque and surface finish during longer production runs, while avoiding overheating or vibration issues common in lighter-duty machines.

What size CNC router table is best for a small production shop?

Most small manufacturers do well with a 24"×36" to 48"×96" work area, depending on material size and workflow. A larger table allows nested sheet layouts and batch cutting, while smaller tables are better for shops focused on compact parts or prototypes.

How can I extend router bit life in production work?

Using Amana Tool Spektra® coated or insert-carbide bits can extend tool life dramatically. Keep bits clean, ensure proper chip evacuation, and maintain correct feed rates and spindle speeds. Regular inspection and timely replacement also prevent costly rework and machine wear.

What accessories improve CNC productivity for small manufacturers?

For consistent, repeatable results, invest in a vacuum hold-down or T-slot clamping system, reliable dust collection, and quality CAM software for efficient nesting and toolpath management. These upgrades reduce setup time, improve surface finish, and maximize machine uptime.