11 Router Bits Every Woodworker Should Own

Table of Contents

Router bits shape, groove, trim, and join wood — making the router one of the most versatile tools in your shop. But with hundreds of bit styles available, it can be tough to know where to start.

This guide breaks down the most essential router bits you should own, what each one does, and when to use it. We’ll also explain key factors like shank size, flute count, and why some bits are better for CNC than handheld routing.

Choosing the Right Router Bit Types: What You Need to Know First

- Bit Types: Straight-Cutting vs. Edge-Forming (Profile) Bits

Straight-Cutting Bits remove material from the interior or edge of a board. These include straight, spiral, flush-trim, rabbeting, and slot-cutting bits.

Edge-Forming Bits shape the outside edges with decorative or functional profiles — like round-over, chamfer, ogee, or cove bits. - Shank Size: 1/4" vs. 1/2"

1/2" shank bits are sturdier, vibrate less, and give cleaner cuts — ideal for full-size routers.

1/4" shank bits are fine for trim routers or light-duty use. - Flute Count: 1, 2, or More?

1-flute bits are more aggressive and clear chips better in softwoods.

2-flute bits offer smoother cuts and are common in most woodworking.

3+ flutes are mostly for CNCs or specialized work where finish matters more than speed. - Plunge vs. Non-Plunge Bits

Only certain bits are designed for plunging into the material vertically (like spiral bits). Don’t try to plunge with a non-plunge bit unless you're routing in from the edge. - Cutting Diameter

This is the width of the cut the bit makes. Common sizes like 1/4" & 1/2" are useful for dadoes, grooves, and rabbets. Larger bits (like 1/2" or more) remove a lot of material quickly — so they require slower feed rates and router speeds to avoid burning or tear-out. Always adjust your settings accordingly. It is often better to remove material in multiple passes. - Handheld vs. CNC Use

Some bits are better suited to CNC use because they handle higher speeds, complex toolpaths, or produce cleaner edges under automated control. For example, spiral bits (especially compression bits) shine in CNC settings. Conversely, edge-forming bits like ogee or round-over are more often used with handheld or table-mounted routers, where the user can guide the bit along the workpiece edge manually.

11 Router Bits Every Woodworker Should Own

1. Straight-Plunge Bit

Great for dadoes, grooves, and mortises. Unlike edge-forming bits, this one cuts straight into the face of the wood.

- Best for: cabinetry, shelves, drawer bottoms

- Sizes to start with: 1/4", 1/2"

- Popular Item: Amana Tool 45201 Solid Carbide Cutting Edge Straight Plunge High Production 5/32" Diameter x 1/4" Shank x 7/16" Cutting Height Router Bit Shop Now

Straight vs. Spiral Plunge Bits: Straight bits are cheaper and fine for basic joinery in softwoods. But spiral bits offer cleaner cuts and better chip evacuation, especially in hardwoods or plywood.

2. Spiral-Plunge Bit

These bits have a spiral cutting edge — upcut, downcut, or compression styles — for cleaner edges and less tear-out.

- Best for: mortises, grooves, and CNC routing

- Tip: Upcut = clean bottoms; Downcut = clean tops; Compression = best of both

- Popular Item: Amana Tool 46415 Solid Carbide Spiral Plunge 1/4" Diameter x 1" Cutting Height x 1/4" Shank x 1" Cutting Height 2-Flute Down-Cut Router Bit Check It Out

3. Flush-Trim Bit

A must-have for trimming laminates, veneers, and template work. The bearing rides along your pattern while the bit cuts flush.

- Best for: pattern routing, veneer, laminates

- Popular Item: Amana Tool 45475 Carbide Tipped Flush Trim Plunge Template 3/8" Diameter x 1/2" Cutting Height x 1/4" Shank w/ 2 Upper Ball Bearings Router Bit See This Bit

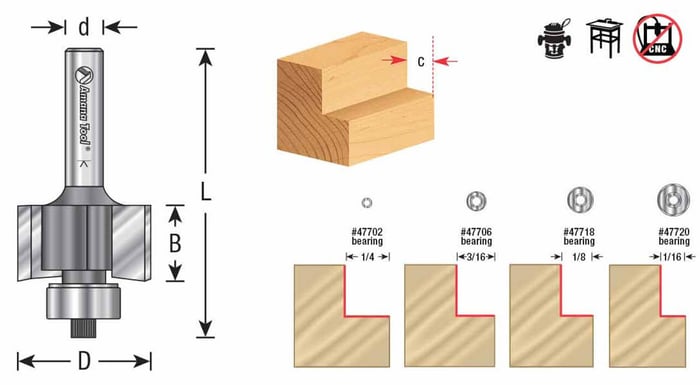

4. Rabbeting Bit

Quickly cuts L-shaped shoulders along the edge. Great for joinery, drawer backs, and cabinet construction.

- Best for: drawer boxes, cabinet backs

- Tip: Look for sets with multiple bearings to adjust the rabbet width.

- Popular Item: Amana Tool 49350 Multi-Rabbet Five Different Rabbet Depths 1-3/8" Diameter x 1/2" Shank x 1/2" Cutting Height Router Bit Shop Now

Like flush-trim bits, rabbeting bits typically feature a pilot bearing.

Unlike flush bits, the cutting blade on a rabbeting bit is not "flush" with the bearing, but instead cuts deeper than the pilot. The bigger the difference, the deeper your rabbet will be.

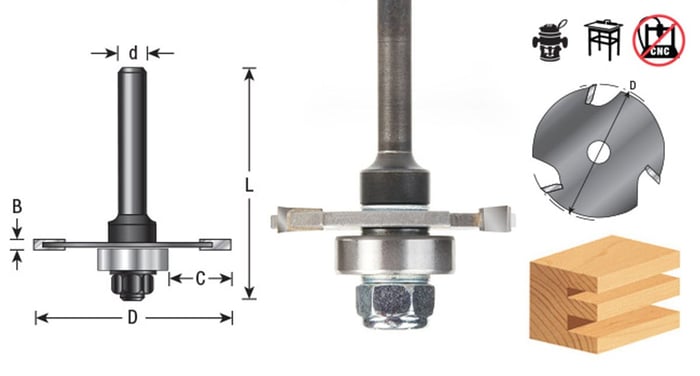

5. Slot-Cutting Bit

Cuts thin grooves into edges for splines, biscuits, or T-moldings. Ideal for cabinetry and flooring.

- Best for: spline joints, edge slots

- Tip: Some models offer interchangeable bearings to vary slot depth.

- Popular Item: Amana Tool 53406 Slotting Cutter Assembly 3 Wing x 1-7/8" Diameter x 1/4" Shank x 1/8" Cutting Height Router Bit See This Bit

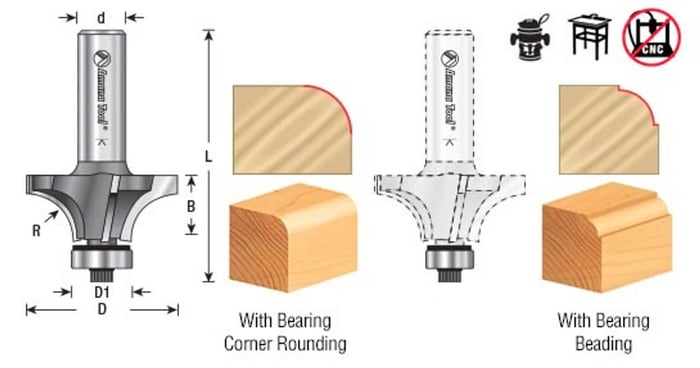

6. Round-Over Bit

Softens square edges for a finished, professional look. The radius determines how much curve you get.

- Best for: tabletops, shelves, frames

- Start with: 1/4" and 3/8" radius sizes

- Popular Item: Amana Tool 49496 Carbide Tipped Corner Rounding 1/8" Radius x 3/4" Diameter x 3/8" Cutting Height x 1/4" Shank w/ Lower Ball Bearing Router Bit Get It Here

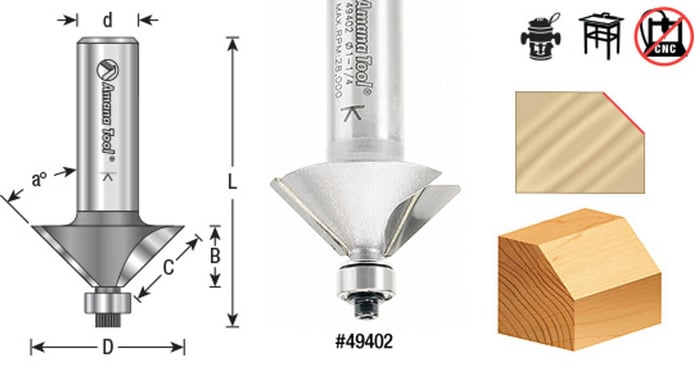

7. 45° Chamfer Bit

Cuts clean beveled edges. Chamfers are decorative but also help ease edges on sharp corners.

- Best for: picture frames, shelves, accent edges

- Tip: Can also be used to create V-grooves by joining two chamfered boards.

- Popular Item: Amana Tool 49400 Carbide Tipped Chamfer 45 Degree x 1-1/4" Diameter x 1/2" Cutting Height x 1/4" Shank w/ Lower Ball Bearing Router Bit Details

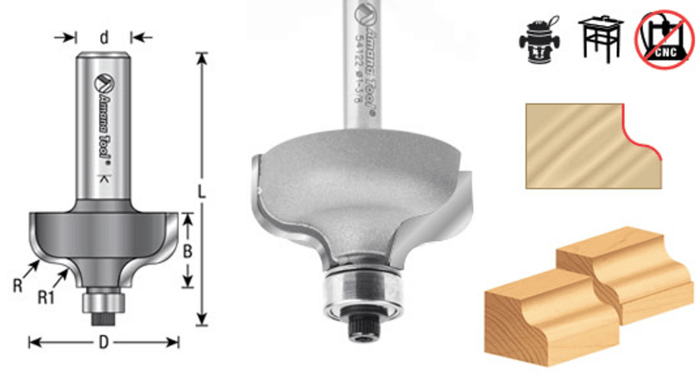

8. Roman Ogee Bit

Classic profile for decorative edge work. Ideal for traditional-style furniture or cabinetry.

- Best for: picture frames, cabinet doors, table edges

- Most common: 1/4" radius

- Popular Item: Amana Tool 49207 Carbide Tipped Roman Ogee 3/8" Radius x 2" Diameter x 1" Cutting Height x 1/2" Shank w/ Lower Ball Bearing Router Bit Get Yours Here

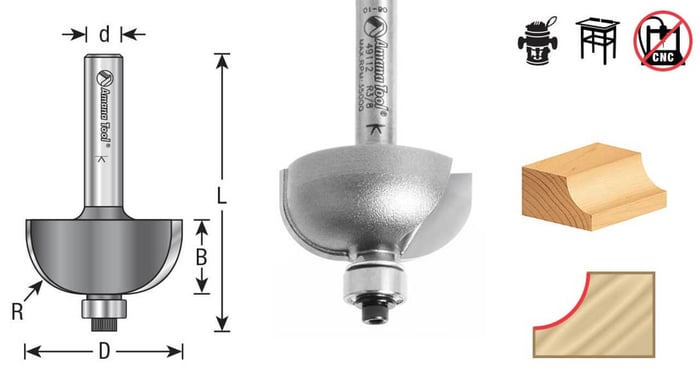

9. Cove Bit

The opposite of a round-over bit — instead of curving out, it curves in. Adds elegant detail to molding and edges.

- Best for: decorative edges, furniture legs

- Start with: 1/4" or 3/8" radius

- Popular Item: Amana Tool 49118 Carbide Tipped Cove 1/2" Radius x 1-3/8" Diameter x 3/4" Cutting Height x 1/2" Shank w/ Lower Ball Bearing Router Bit Shop Now

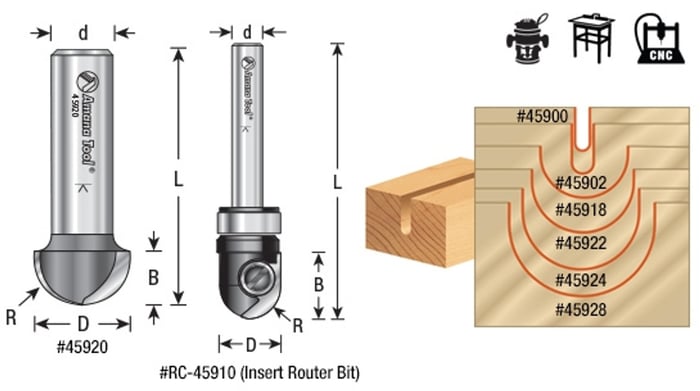

10. Core-Box Bit

This is a plunge bit. Creates round-bottomed grooves — perfect for flutes, engraving, or shallow carving.

They’re also perfect for juice grooves, or drip grooves - those shallow channels routed near the edge of a cutting board to catch juices from meat, fruit, or other juicy foods, so the liquid doesn’t spill off the board and make a mess on the counter.

- Best for: columns, panels, wooden signs

- Versatile sizes: 1/4" and 3/8" diameters

- Popular Item: Amana Tool 45926 Carbide Tipped Core Box 1/2" Radius x 1" Diameter x 11/16" Cutting Height x 1/2" Shank Router Bit More Details

11. V-Groove Bit

I guess you can call it a plunge bit? It's definitely not a profile bit. It's really the start of a whole new category of carving & engraving bits. But that's a discussion for another day.

Cuts V-shaped decorative grooves or lettering. A go-to for sign makers and panel detailing.

- Best for: signmaking, decorative grooves

- Start with: 90° cutting angle

- Popular Item: Amana Tool 45704 Carbide Tipped V Groove 90 Degree x 1/2" Diameter x 1/4" Cutting Height x 1/4" Shank Router Bit Most Popular V-Groove

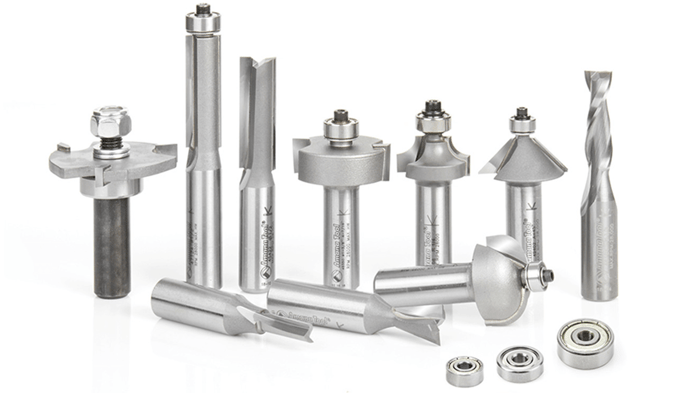

Should You Buy a Router Bit Set?

Should You Buy a Router Bit Set?

Starter sets are great if you’re just getting into woodworking and want to experiment with multiple cuts. Look for:

- Carbide tips – longer-lasting and cleaner cutting than HSS

- 1/2" shank – more stable and durable

- Well-labeled case – to help you actually find the bit you need

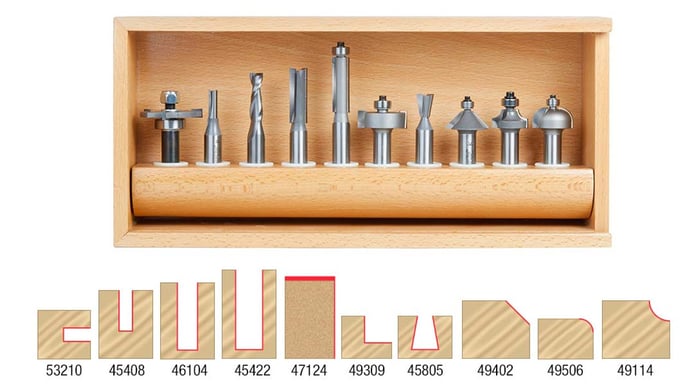

- Popular Set: Amana Tool AMS-410 10-Pc Woodworkers Must Have Router Bit Set 1/2" Shank Set

- For handheld routers accepting 1/4" bits only, you can't go wrong with the Timberline TRS-120 12-Piece Carbide Tipped Router Bit Set 1/4 Inch Shank. 1/4" Shank Set

- No set is perfect. The AMS-410 contains:

- Amana Tool 53210 Slotting Cutter 3 Wing x 1-7/8" Diameter x 1/4" Cutting Height x 5/16" Inner Diameter

- Includes Amana Tool 47605 Router Arbor with Hex Nuts, Washers and Ball Bearing, and 3 ball bearing guides (1/2", 5/8", & 3/4")

- Amana Tool 45408 Solid Carbide Cutting Edge Straight Plunge High Production 1/4" Diameter x 3/4" Cutting Height x 2-1/2" Long 1/2" Shank Router Bit Details

- Amana Tool 46104 Solid Carbide Spiral Plunge 3/8" Diameter x 1-1/4" Cutting Height x 1/2" Shank x 3" Long 2 Flute Up-Cut Router Bit Get It Here

- Amana Tool 45422 Carbide Tipped Straight Plunge High Production 1/2" Diameter x 1-1/2" Cutting Height x 1/2" Shank x 3-1/8" Long Router Bit Available Individually

- Amana Tool 47124 Carbide Tipped Flush Trim 1/2" Diameter x 1-1/2" Cutting Height x 1/2" Shank x 3-7/8" Long Router Bit w/ Lower Ball Bearing

Just the Flush Trim - Amana Tool 49309 Rabbeting 1/2" Depth x 1-3/8" Diameter x 1/2" Cutting Height x 1/2" Shank Router Bit Shop Now

- Amana Tool 45805 Carbide Tipped Dovetail 10 Degree x 1/2" Diameter x 5/8" Cutting Height x 1/2" Shank Router Bit Add a Dovetail Bit

- Amana Tool 49402 Carbide Tipped Chamfer 45 Degree x 1-1/4" Diameter x 1/2" Cutting Height x 1/2" Shank w/ Lower Ball Bearing Router Bit See More

- Amana Tool 49506 Carbide Tipped Corner Rounding 1/4" R x 1" Inch Diameter x 1/2" Cutting Height x 1/2" Shank w/ Lower Ball Bearing Router Bit Check It Out

- Amana Tool 49114 Carbide Tipped Cove 3/8" Radius x 1-1/8" Diameter x 9/16" Cutting Height x 1/2 Shank w/ Lower Ball Bearing Router Bit Details

- Amana Tool 53210 Slotting Cutter 3 Wing x 1-7/8" Diameter x 1/4" Cutting Height x 5/16" Inner Diameter

So 2 straight-plunge; 1 spiral; no v-groove bit; and instead of an ogee, you get a dovetail bit.

Which is a really cool bit, dovetails are awesome -- but "12 Router Bits Everyone Should Own" just doesn't have the same ring. :)

Final Tips

- Use the right speed. Larger bits need slower RPMs to avoid burning.

- Secure your material. Especially with aggressive plunge cuts.

- Let the bit do the work. Don’t force the cut — that’s how you burn wood and dull bits.

Explore Pro-Quality Router Bits at ToolsToday

We carry top-of-the-line carbide router bits from Amana Tool — trusted by woodworkers and signmakers worldwide. Whether you're working by hand or on a CNC, you'll find the right bit for the job.

FAQs

What are the most essential router bits for general woodworking?

The foundational bits every woodworker should own include straight-plunge, round-over, flush-trim, rabbeting, and slot-cutting bits. These cover a wide range of basic joinery, edge profiling, and template routing tasks .

What’s the difference between straight-plunge and spiral-plunge router bits? When should I use each?

Straight-plunge bits are cost-effective and great for general cuts like grooves and mortises. Spiral-plunge bits (upcut, downcut, or compression) offer cleaner edges and better chip removal—excellent for hardwood, plywood, or CNC work.

How do I choose between a 1/4″ and 1/2″ shank router bit?

A 1/2″ shank is sturdier, vibrates less, and delivers cleaner cuts—ideal for larger handheld routers. A 1/4″ shank is sufficient for trim routers or light-duty applications.

Which router bit is best for decorative edge profiles like ogee or cove?

Roman ogee bits create classic ornate furniture edges; cove bits carve inward curves for elegant molding details. Round-over bits soften edges with smooth curves—choose based on the desired aesthetic.

What’s the purpose of a flush-trim bit?

Flush-trim bits, with a guide bearing, are essential for trimming laminates, veneers, or following templates—ensuring perfectly flush edges.

Why and when should I use a rabbeting or slot-cutting bit?

Rabbeting bits quickly cut L-shaped shoulders along edges for joinery in drawers or cabinets. Slot-cutting bits are ideal for creating grooves for splines, biscuits, or T-molding—especially useful in cabinetry and flooring.

Can I plunge with any router bit?

No—only plunge / plungeable bits (like spiral-plunge types) are designed for vertical plunging. Non-plunge bits shouldn’t be plunged unless routing from an edge, as misuse can damage the bit or material (or both).

Should I buy a router bit set or individual bits?

While sets can offer savings and convenience, many woodworkers recommend buying individual high-quality bits as needed to avoid paying for bits you may never use.

Which router bits are best for CNC versus handheld use?

CNC routing benefits from spiral bits (especially compression) for chip control at high speeds. Handheld or table routing typically uses edge-forming bits like ogee or round-over, where manual guidance is key.

How do flute counts affect router bit performance?

Single-flute bits are more aggressive and better at clearing chips—great for softwoods. Two-flute bits offer smoother cuts and are widely used. Three or more flutes are designed for CNC or tasks where edge finish is the priority.