Saw Blade Tooth Geometry: The Secret to a Perfect Cut

Table of Contents

Not all "circular" blades are created equal. The right saw blade turns rough lumber into clean, precise cuts — while the wrong one burns, chips, or tears your material. In this guide, we’ll break down the different types of saw blades by material, machine, and tooth geometry so you can match every cut to the perfect blade and get pro-level results in your shop.

First, a definition: Geometry?

Blade geometry—the shape, angle, and spacing of each tooth—determines how a blade shears, scrapes, or slices through material. Choose the geometry for your material and cut type to get cleaner edges and longer blade life.

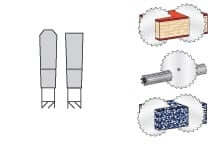

ATB – Alternate Top Bevel

Best for: Crosscutting wood, plywood, MDF, laminates

Each tooth is beveled alternately left and right, acting like tiny scissors that slice fibers.

- Clean finish, reduced tear-out

- Typically slower feed than ripping grinds

Pro Tip: Choose Hi-ATB for melamine/laminate when you need ultra-clean edges.

FTG – Flat Top Grind

Best for: Ripping solid wood

Square, flat teeth chip material straight out of the kerf.

- Fast, durable, efficient

- Rougher surface; plan to sand or plane

TCG – Triple-Chip Grind

Best for: Non-ferrous metals, plastics, laminates

Alternates a trapezoidal “chipper” tooth with a flat raker for burr-resistant, durable cutting.

- Smooth cuts in aluminum/acrylic

- Resists chipping and heat wear

Hi-ATB – High Alternate Top Bevel

Best for: Veneer, melamine, thin laminates

Steeper bevels (≈30–40°) slice like a razor for show-face panels.

- Superb edge quality

- Dulls faster; reserve for fine work

ATB+R – Combination Grind

Best for: All-purpose jobsite use

Groups of ATB teeth followed by a flat raker balance crosscutting and ripping.

Hollow Ground

Best for: Laminates, veneers, plastics

Concave faces slice smoothly without chipping or burning; leaves a polished edge.

Quick Geometry Reference

| Grind Type | Cut Style | Finish | Best For |

|---|---|---|---|

| FTG | Ripping | Fair | Solid wood |

| ATB | Crosscutting | Excellent | Wood, plywood |

| Hi-ATB | Crosscutting (ultra-fine) | Superb | Melamine, veneer |

| TCG | Specialty | Smooth | Non-ferrous, plastics, laminates |

| ATB+R | Combination | Very good | All-purpose |

| Hollow Ground | Finish | Glass-smooth | Veneer, acrylic |

Takeaway: Pick geometry for the material and cut. That’s the shortest path to cleaner edges and longer blade life.

See our page, Saw Blade Terminology, for more information.

Hook (Rake) Angle Explained

While tooth geometry defines how each tooth cuts, the hook angle—the forward or backward tilt of each tooth—controls how aggressively the blade feeds through the material.

- Positive Hook (10°–22°): The teeth lean forward, pulling the blade into the cut quickly. Great for ripping softwood or fast feed rates.

- Low or Neutral Hook (0°–6°): Provides control for crosscuts or hardwoods where tear-out is a concern.

- Negative Hook (–2° to –6°): The teeth lean slightly backward, reducing “grab.” Ideal for melamine, laminates, aluminum, and plastics.

Tip: Miter saws and radial arm saws often use negative or low hook angles to keep the blade from feeding too aggressively into the workpiece.

Clearance Angles and Tooth Life

Each tooth also has clearance angles that prevent friction and burning as it passes through the cut:

- Top Clearance (12°–15°): The relief behind the tooth’s cutting edge, ensuring it doesn’t rub the surface after the cut.

- Side Clearance (1°–2°): The slight taper on each side of the tooth that minimizes drag and keeps the blade cool.

These subtle angles protect both the workpiece and the carbide tip. Too little clearance causes heat buildup and burning; too much can weaken the tooth or lead to vibration.

Material-Specific Geometry Quick Reference

| Material | Suggested Geometry | Why It Works |

|---|---|---|

| Melamine / Double-Sided Panels | Hi-ATB + Negative Hook + Shallow Gullets | Chip-free edges and smooth surfaces on coated panels. |

| Aluminum / Non-Ferrous Metals | TCG + Negative Hook + Thick Plate | Burr-free cuts, less grabbing, and reduced vibration. |

| Solid Hardwood (Ripping) | FTG + Positive Hook (~20°) + Deep Gullets | Efficient chip removal and fast feed rates. |

| Plywood / Veneered Panels | ATB + Low Hook + High Tooth Count | Clean crosscuts without splintering delicate veneers. |

Tip: The perfect geometry combines the right tooth shape, hook angle, and gullet size for the material—not just the number of teeth.

When Geometry Goes Wrong

Using the wrong geometry can cause chatter, burning, or chip-out. For example, a high positive hook on melamine may pull the board into the blade and tear the surface, while a dull Hi-ATB edge can burn instead of slice. Always check that the grind and hook match your material and saw type.

The right saw blade doesn’t just change your cut — it changes your work. Whether you’re crosscutting solid wood, trimming melamine panels, or slicing through aluminum, understanding blade geometry and material matching will save you time and deliver cleaner, smoother results.

Explore our full selection of Amana Tool® Saw Blades, and find the perfect blade for your next project.

FAQs

What does saw blade tooth geometry mean?

Tooth geometry refers to the shape, angle, and spacing of the teeth on a saw blade. Each geometry—like ATB, FTG, or TCG—is designed for specific materials and cut types. The right geometry helps you get smoother cuts, reduce tear-out, and extend the life of your blade.

What’s the difference between ATB, FTG, and TCG saw blades?

- ATB (Alternate Top Bevel): Angled teeth alternate left and right for smooth crosscuts in wood and plywood.

- FTG (Flat Top Grind): Flat teeth for fast ripping in solid wood.

- TCG (Triple-Chip Grind): A mix of trapezoidal and flat teeth for cutting metals, plastics, and laminates cleanly.

Each geometry has a specific purpose—using the right one means cleaner results and less wear on your tools.

Why would I choose a Hi-ATB blade instead of a standard ATB?

Hi-ATB blades have a steeper bevel angle, which slices wood fibers more aggressively. That makes them perfect for coated panels, veneers, and melamine where chip-free edges matter. The trade-off? They dull faster than standard ATB blades, so reserve them for fine finishing work.

What does ATB+R mean on a saw blade?

ATB+R (Alternate Top Bevel + Raker) describes a combination grind—groups of ATB teeth followed by one flat-top “raker” tooth. It’s a versatile geometry that performs well for both ripping and crosscutting, making it a favorite for general-purpose blades.

How do I know which tooth geometry to use for my project?

Match your geometry to the material and type of cut:

- FTG for fast rips in solid wood.

- ATB for crosscuts in wood and plywood.

- Hi-ATB for laminates and melamine.

- TCG for metal and plastic.

- Hollow Ground for ultra-smooth edges on veneer or acrylic.

When in doubt, check the blade’s labeling or ToolsToday product page—it’ll specify the recommended materials and cut direction.